Fabrication method of stainless steel embossed pot

A production method and stainless steel technology, applied in the field of metal pressure processing, can solve the problems of poor three-dimensional effect and difficult processing of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

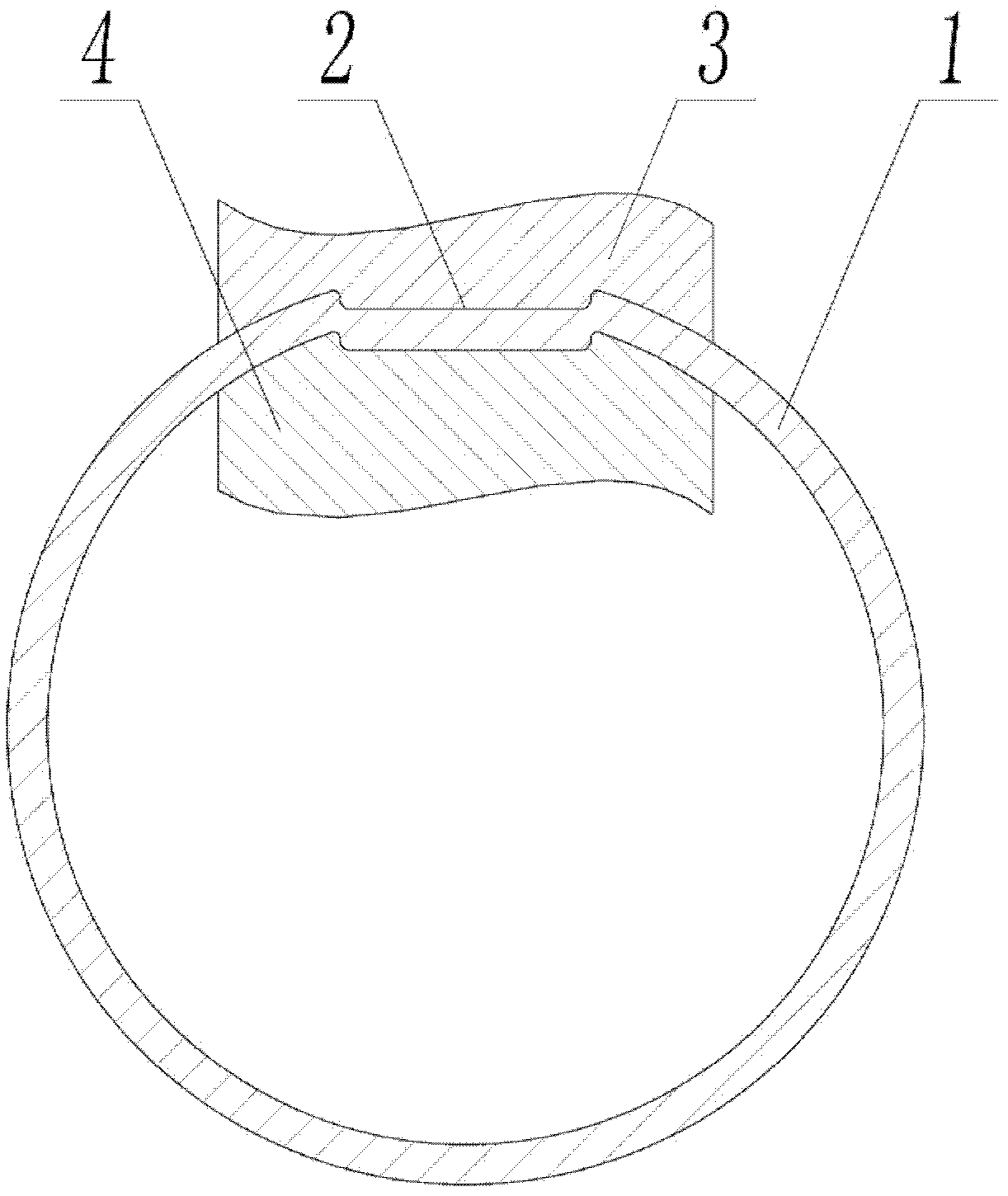

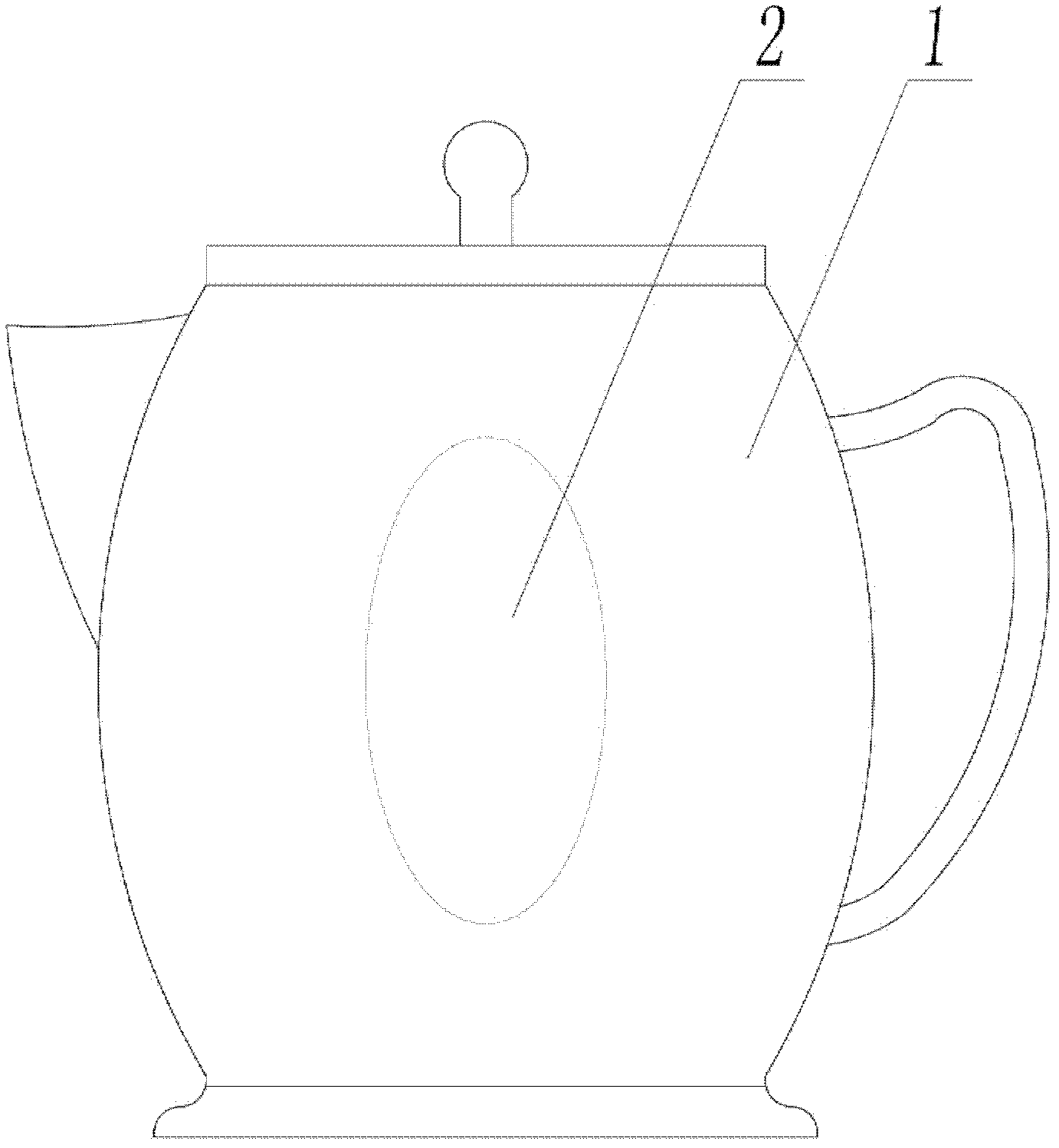

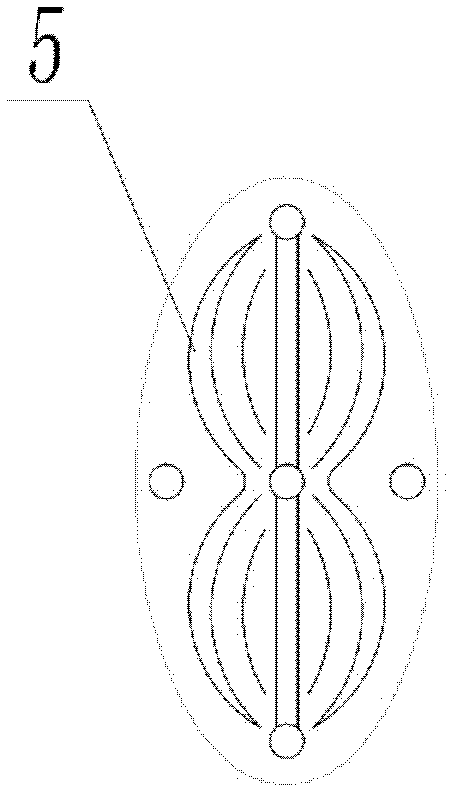

[0022] figure 1 It is a schematic diagram of the pressing and forming of the flower-shaped pool of the stainless steel embossing pot, figure 2 It is a schematic diagram of a stainless steel embossing pot with a flower-shaped pool. like figure 2 As shown, the profile shape of the flower-shaped pool 2 is oval. When pressing the flower-shaped pool 2 on the stainless steel pot body 1, the flower-shaped pool mold is used to press the inwardly concave oval flower-shaped pool 2 on the surface of the stainless steel pot body. The upper die 3 of the flower-shaped pool mold is a punch, and the punch is installed on the upper head of the molding equipment. The lower die 4 of the flower-shaped pool mold is a die, and the die is installed on the support arm opposite to the punch. The supporting arm of the die stretches into the inside of the kettle body 1, and then the upper pressure head equipped with the punch is pressed down, thereby pressing the inwardly recessed flower-shaped pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com