Front cabin flume assembly and mounting method thereof

An installation method and the technology of the water tank, which are applied in the sub-assembly of the upper structure, transportation and packaging, and the upper structure, can solve the problems of waste of space, difficulty in assembly, error of the front cabin water tank assembly, etc., and achieve simplified layout and guaranteed Finished product quality, effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

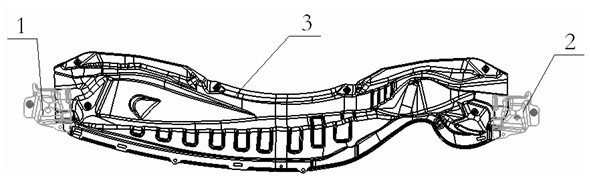

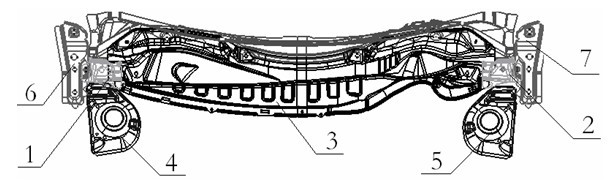

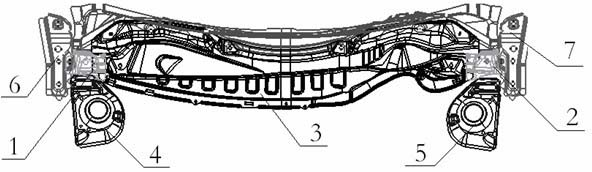

[0019] Such as figure 1 As shown, the front cabin running water tank of the present embodiment is formed by welding three sections of front cabin running water tank bodies 1, 2, 3, wherein the front cabin running water tank bodies 1, 2 are provided with bolt holes.

[0020] The installation method of the above-mentioned front cabin gutter assembly includes the following steps:

[0021] A: Weld the front cabin water tank body 1, 2, and 3 together to form the front cabin water tank assembly;

[0022] B: Install the left and right front wheel house shock absorbers 4 and 5 on the car body;

[0023] C: Connect the two ends of the front cabin gutter assembly to the corresponding car connection plates 6 and 7 with bolts.

[0024] In the above-mentioned installation method, after the installation of the shock absorber is completed, the bolts are used to fix the front compartment water tank assembly, so that there is no need to leave space for the installation tool of the shock absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com