Upper cover of mixing and transporting device for high-flowability asphalt mixture

An asphalt mixture, mixing and transportation technology, applied in roads, road repair, roads, etc., can solve the problems of affecting the appearance of equipment, difficult to collect and waste asphalt materials, etc., and achieve the effects of low maintenance costs, normal operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

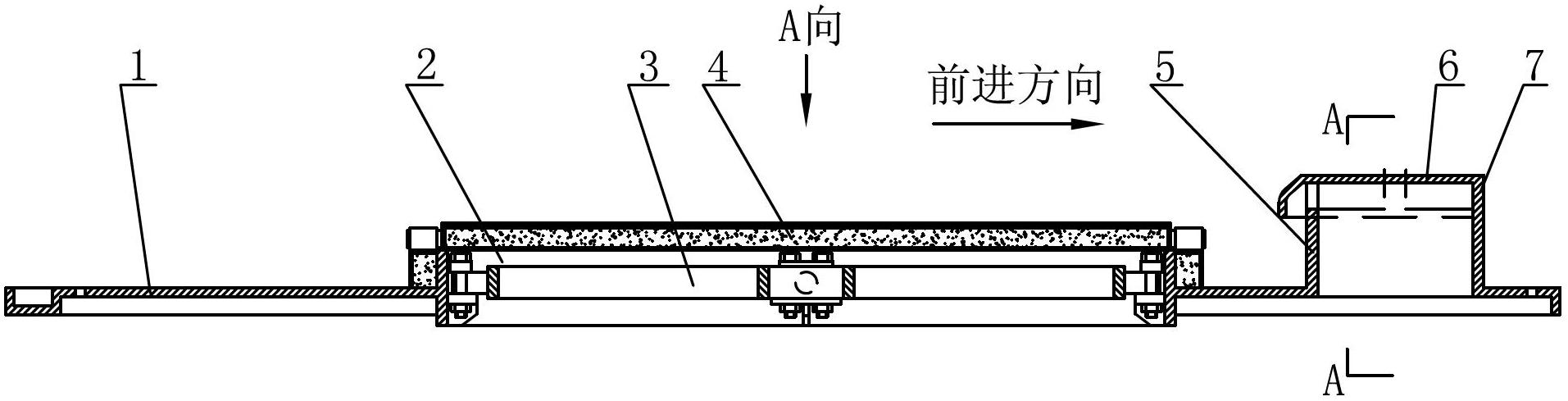

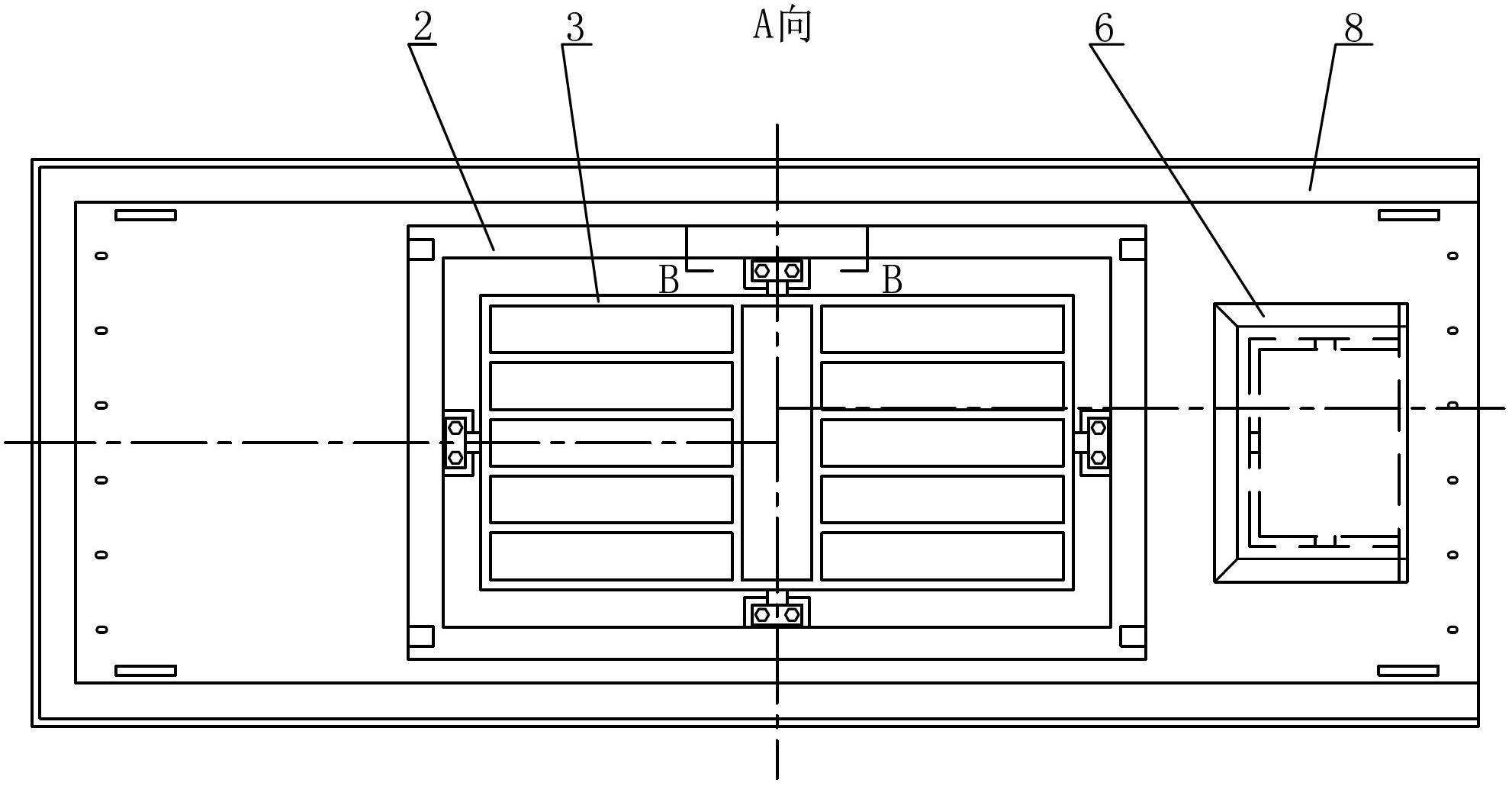

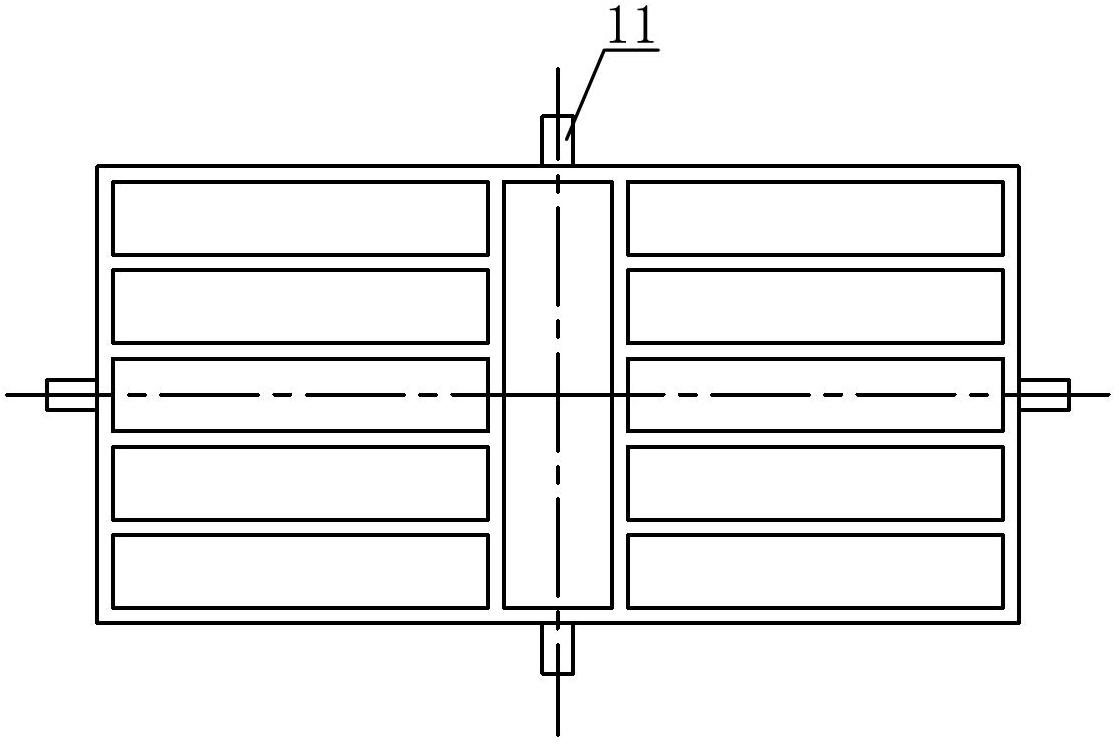

[0020] exist Figure 1~6 Among them, the upper cover of the large-fluidity asphalt mixture mixing and transportation equipment in this embodiment consists of an upper cover plate 1, a feed port 2, a filter screen 3, a door leaf 4 at the feed port, a rear side plate 5 of the smoke exhaust port, and a smoke exhaust hood 6 , smoke outlet front side plate 7, diversion groove 8, smoke outlet left side panel 9, smoke outlet right side panel 10, positioning block 11, support plate 12, smoke outlet 13, pressure plate 14, bolt 15, U Shape bolt 16 connection forms.

[0021] In order to facilitate the further understanding of the present invention, it is defined as that the advancing direction of the large fluidity asphalt mixture mixing and transporting equipment is the front.

[0022] The middle part of the upper cover plate 1 is processed with a feed inlet 2, and the asphalt mixture is added from the feed inlet 2, and the left, right, and rear edges of the upper surface of the upper ...

Embodiment 2

[0025] In this embodiment, the front side plate 7 of the smoke exhaust port and the rear side plate 5 of the smoke exhaust port are welded and connected with the left side plate 9 of the smoke exhaust port and the right side plate 10 of the smoke exhaust port to form a smoke exhaust pipe. The shape of the smoke exhaust pipe is Square column cylindrical body, the smoke exhaust pipe is connected with the combustion chamber of the large fluidity asphalt mixture mixing and transportation equipment, the upper end of the smoke exhaust pipe is covered with a smoke exhaust hood 6, and the front end of the smoke exhaust hood 6 is connected to the front side plate of the smoke exhaust port 7 is connected as a whole, there is a distance between the rear side wall of the exhaust hood 6 and the rear side plate 5 of the smoke exhaust port, a distance is maintained between the left side wall and the left side plate 9 of the smoke exhaust port, and a distance is maintained between the right sid...

Embodiment 3

[0027] In this embodiment, the front side plate 7 of the smoke exhaust port and the rear side plate 5 of the smoke exhaust port are welded and connected with the left side plate 9 of the smoke exhaust port and the right side plate 10 of the smoke exhaust port to form a smoke exhaust pipe. The shape of the smoke exhaust pipe is Square column cylindrical body, the smoke exhaust pipe is connected with the combustion chamber of the large fluidity asphalt mixture mixing and transportation equipment, the upper end of the smoke exhaust pipe is covered with a smoke exhaust hood 6, and the front end of the smoke exhaust hood 6 is connected to the front side plate of the smoke exhaust port 7 is connected as a whole, there is a distance between the rear side wall of the exhaust hood 6 and the rear side plate 5 of the smoke exhaust port, a distance is maintained between the left side wall and the left side plate 9 of the smoke exhaust port, and a distance is maintained between the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com