Connected support applicable to mounting precast beam

A technology of prefabricated beams and joints, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as uneven force, increased noise, construction cost, management, quality control difficulties, etc., to achieve convenient construction, firm connection, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

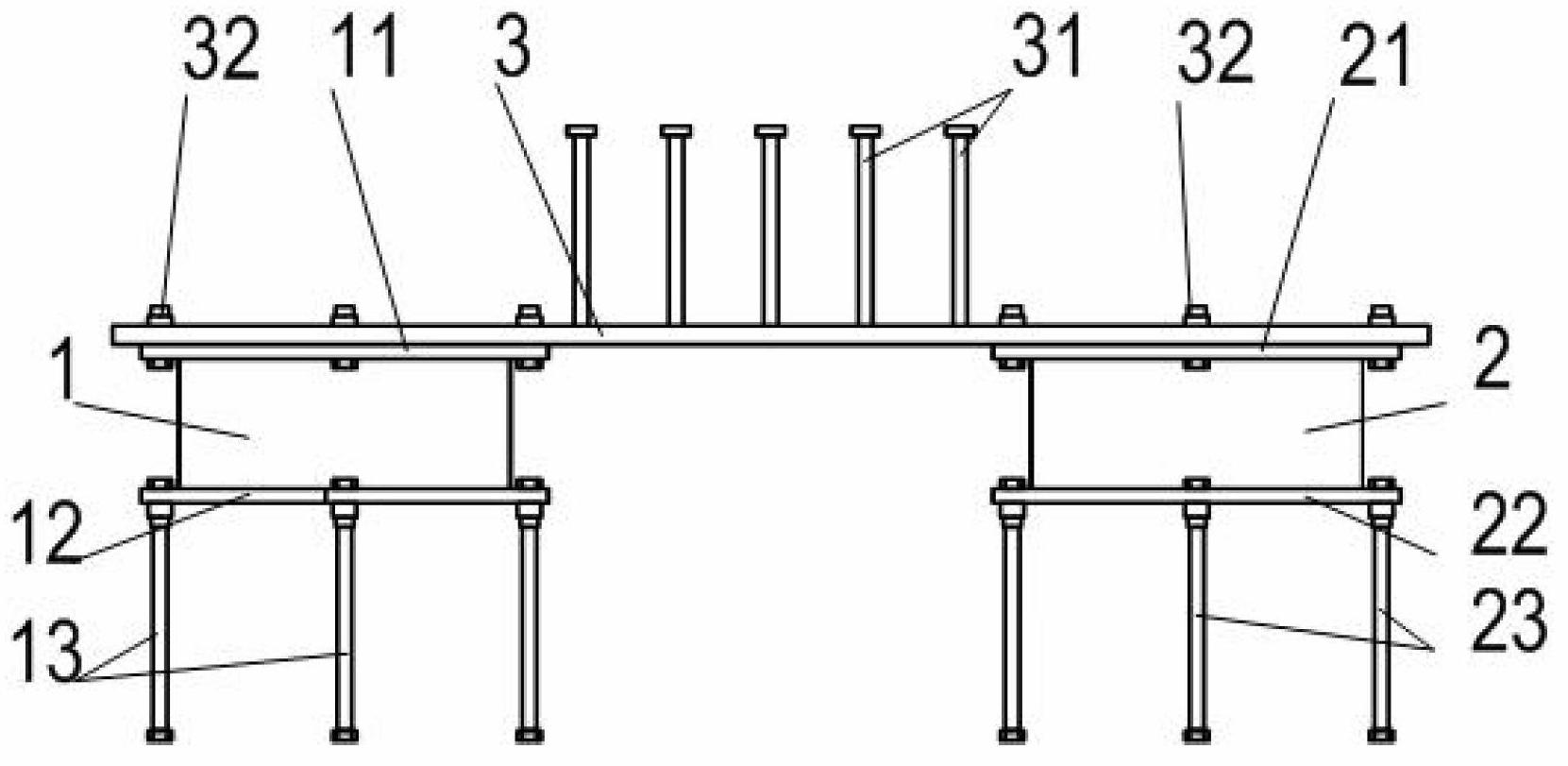

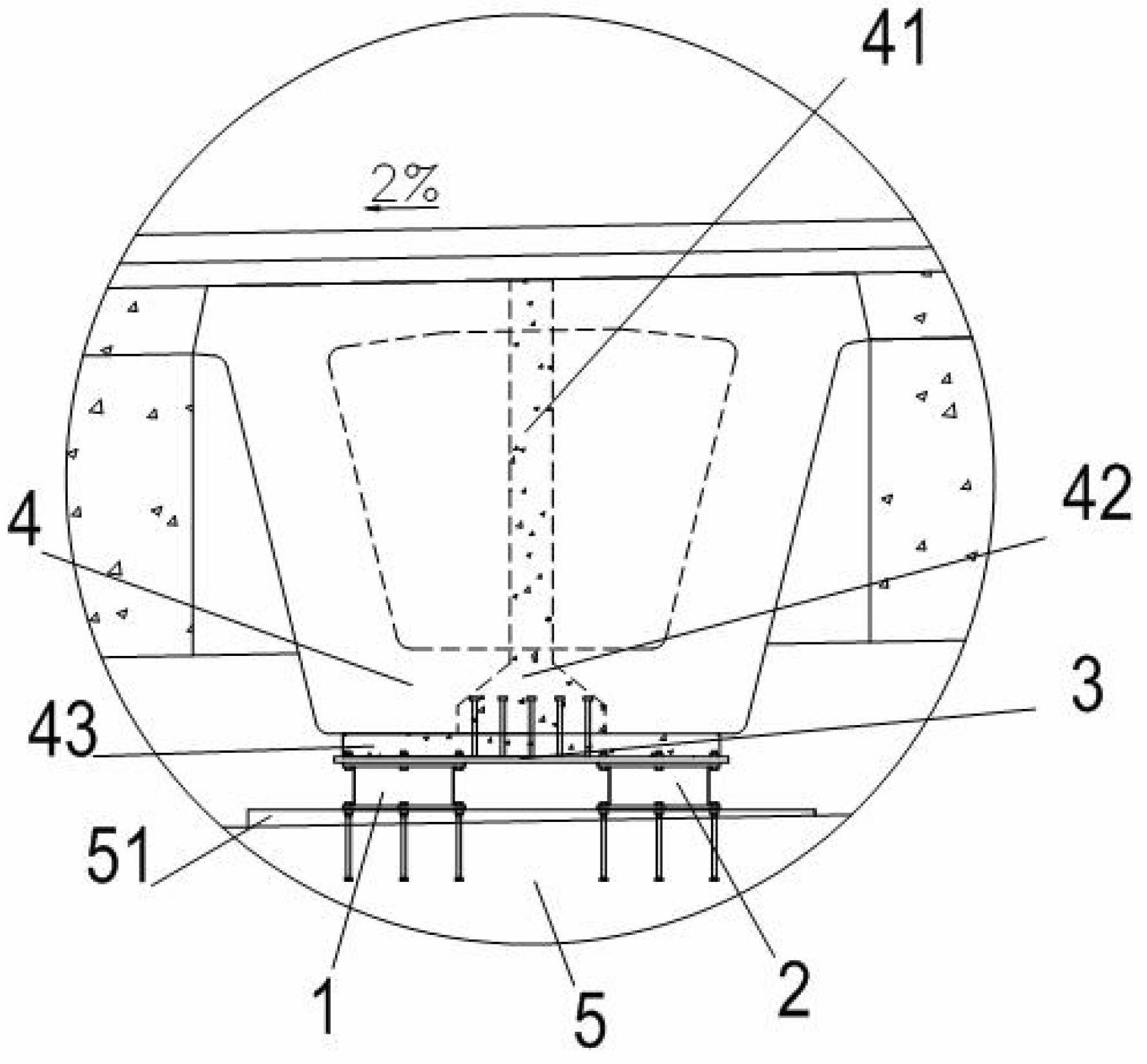

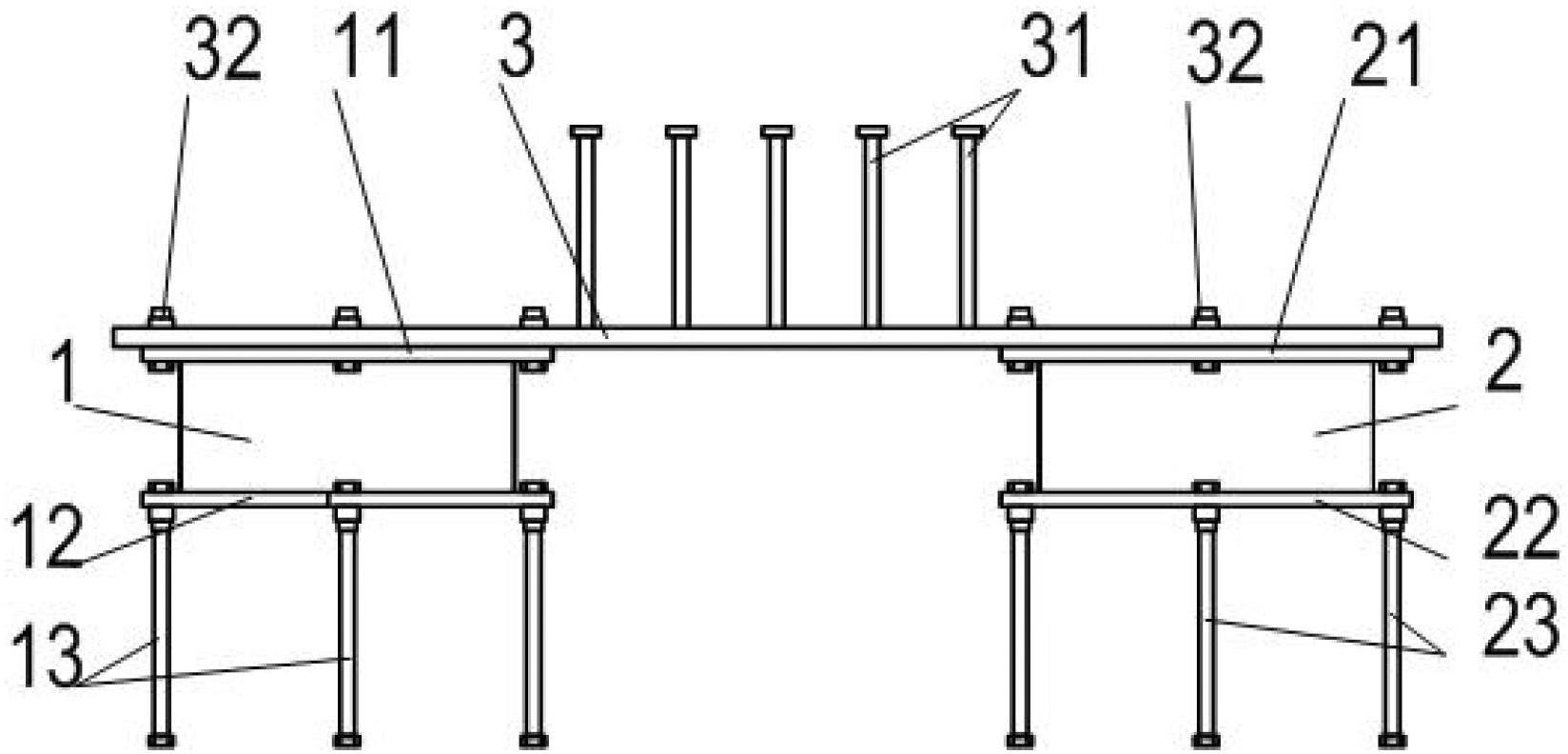

[0017] Such as figure 1 , figure 2 As shown, a specific embodiment of the conjoined support suitable for the installation of prefabricated beams of the present invention mainly includes a conjoined steel plate 3, and the upper side of the conjoined steel plate 3 is provided with a plurality of upper positioning parts fixedly connected with the prefabricated beam 4. Connector 31. The lower side of the conjoined steel plate 3 is fixedly connected to the first support main body 1 through the first upper steel plate 11 , and is fixedly connected to the second support main body 2 through the second upper steel plate 21 .

[0018] The special feature of the present invention is that the upper positioning connector 31 is located between the first support body 1 and the second support body 2 . The upper positioning connector 31 is set between the first support body 1 and the second support body 2 (also the middle position of the prefabricated beam 4 hoisted later) instead of on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com