Force moment measuring device and usage thereof

A technology of torque measurement and torque wrench, applied in the direction of torque/torsional force when tightening, can solve the problem of not being able to guarantee 100% qualified, and achieve the effect of eliminating installation quality accidents, easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

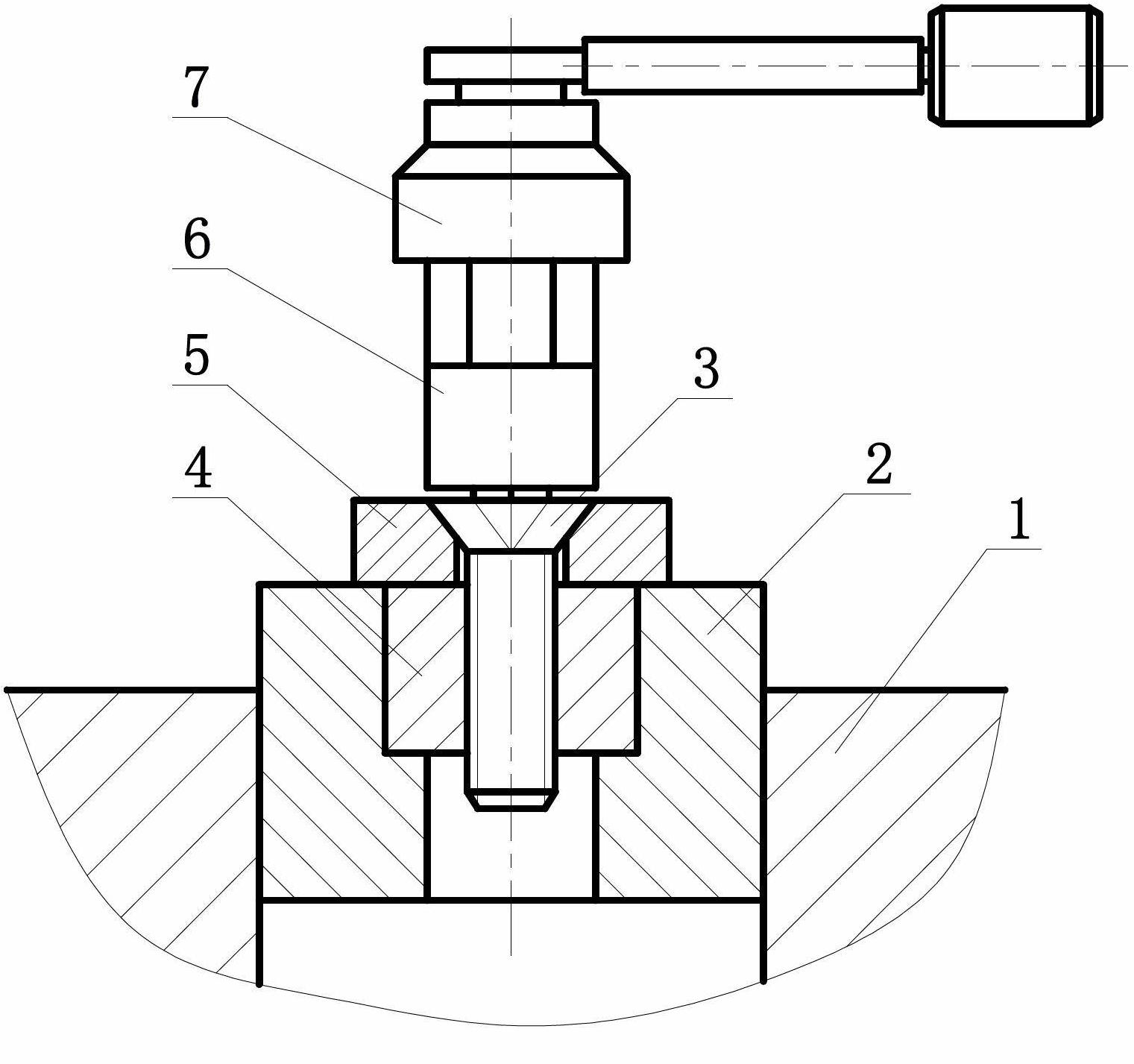

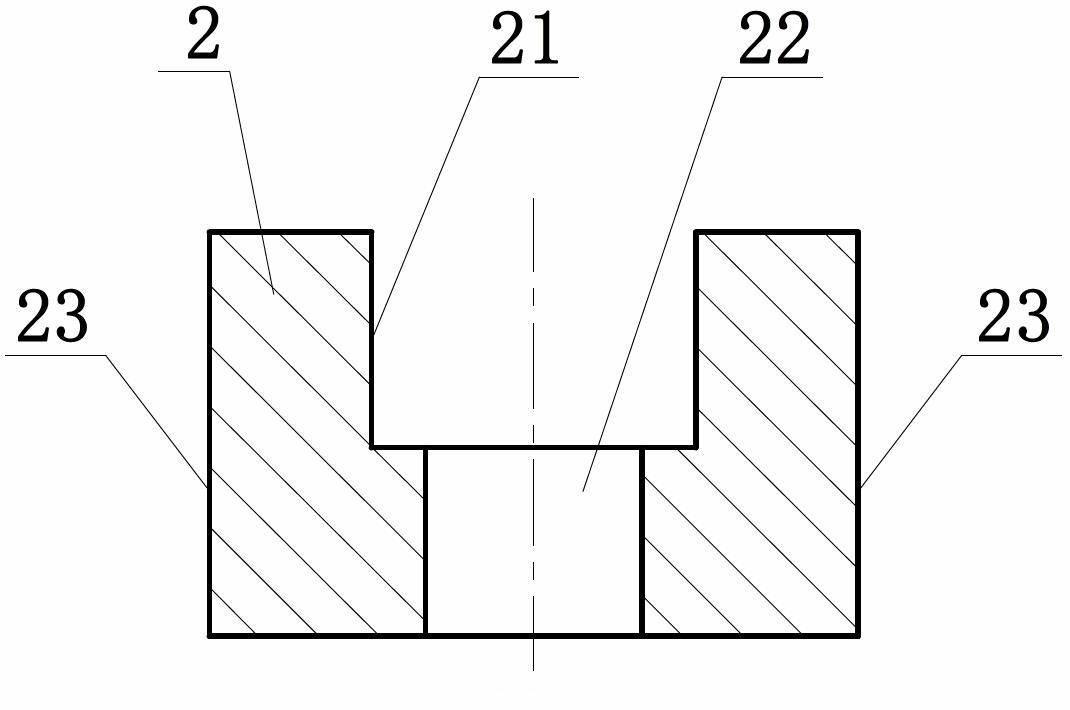

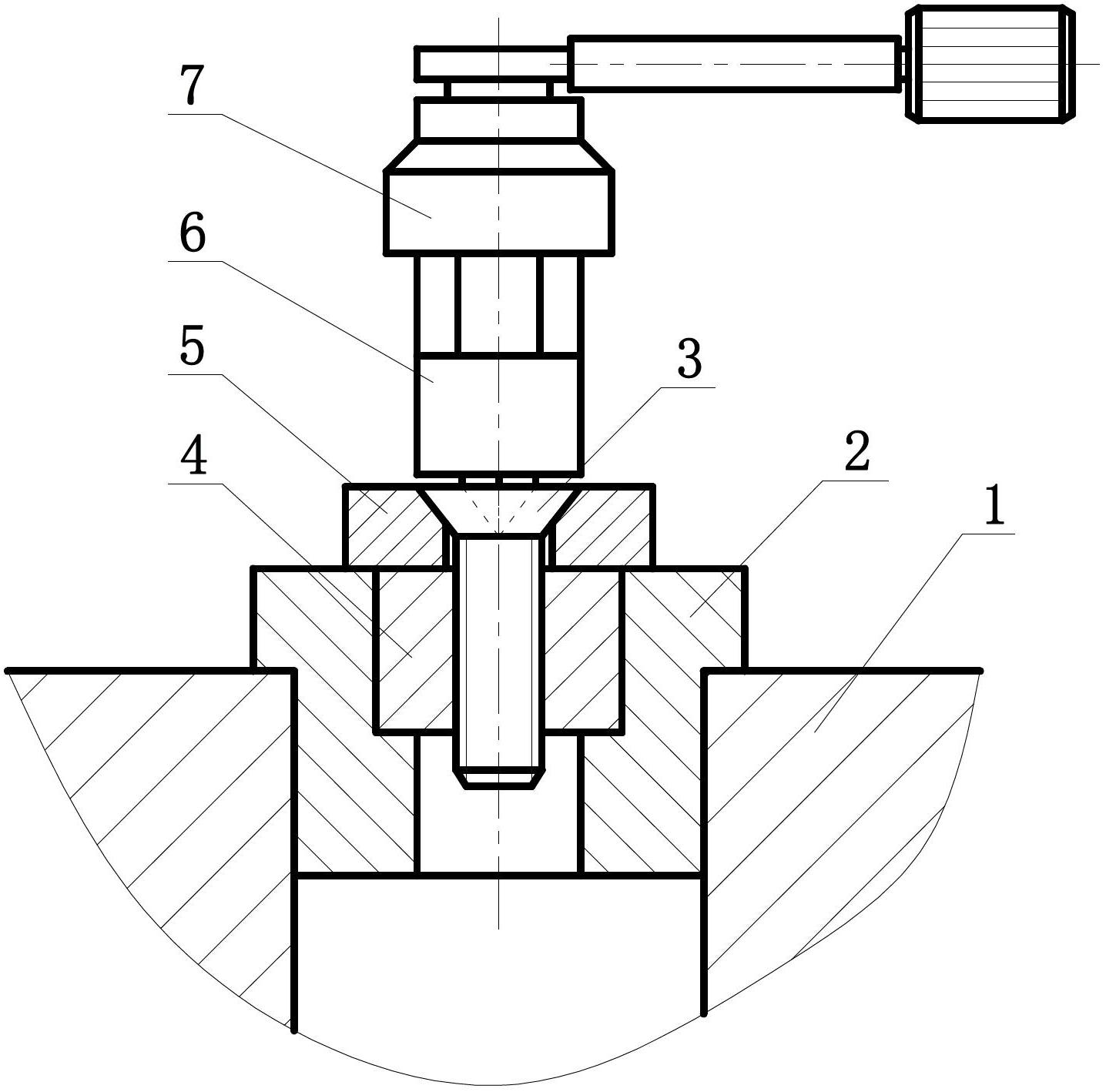

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention is a torque measuring device, comprising a positioning block 2, a hexagonal nut 4, a cross-recessed punch 6, and a torque wrench 7, such as figure 2 As shown, the upper end surface of the positioning block 2 has a groove 21 for placing a hex nut, and a through hole 22 is opened on its lower end surface, the groove 21 is connected with the through hole 22, and the positioning block 2 is also provided with two mutually parallel Clamping surface 23, the clamping surface 23 is symmetrical with respect to the central axis of the through hole 22 on the positioning block 2, the clamping surface 23 and the upper end surface of the positioning block are vertically intersected, in order to make the hexagonal nut 4 position, prevent its rotation, the hexagonal Position the nut 4 and prevent the hexagonal nut 4 from rotating. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com