Capacitive touch screen

A capacitive touch screen and conductive film technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems affecting the appearance of the touch screen, touch screen bubbles, poor function, etc., to improve quality and aesthetic effect, The effect of reducing the formation of air bubbles and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below.

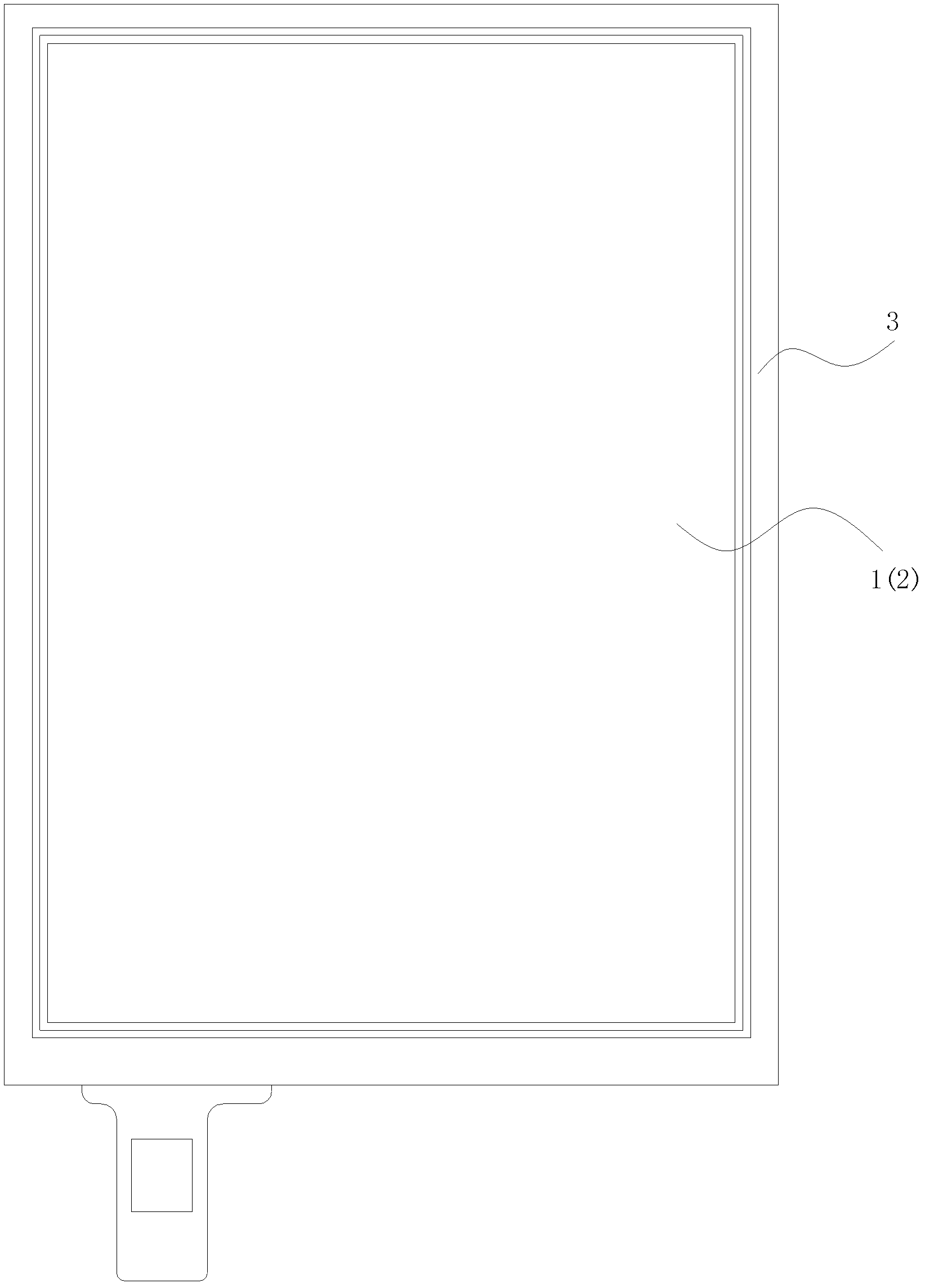

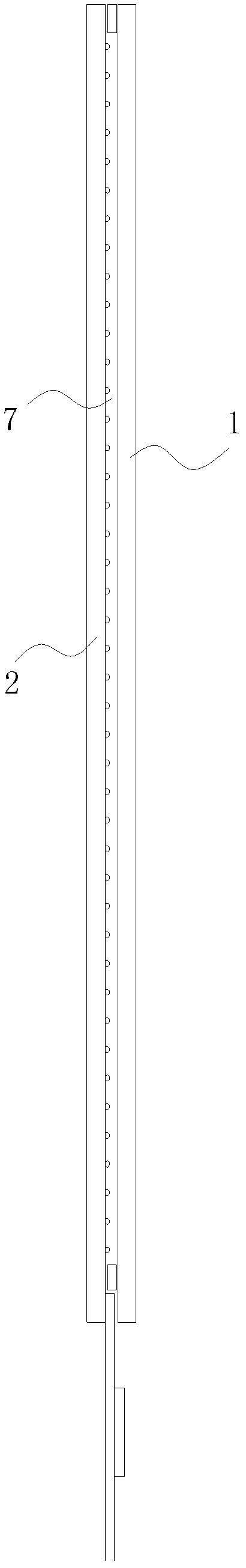

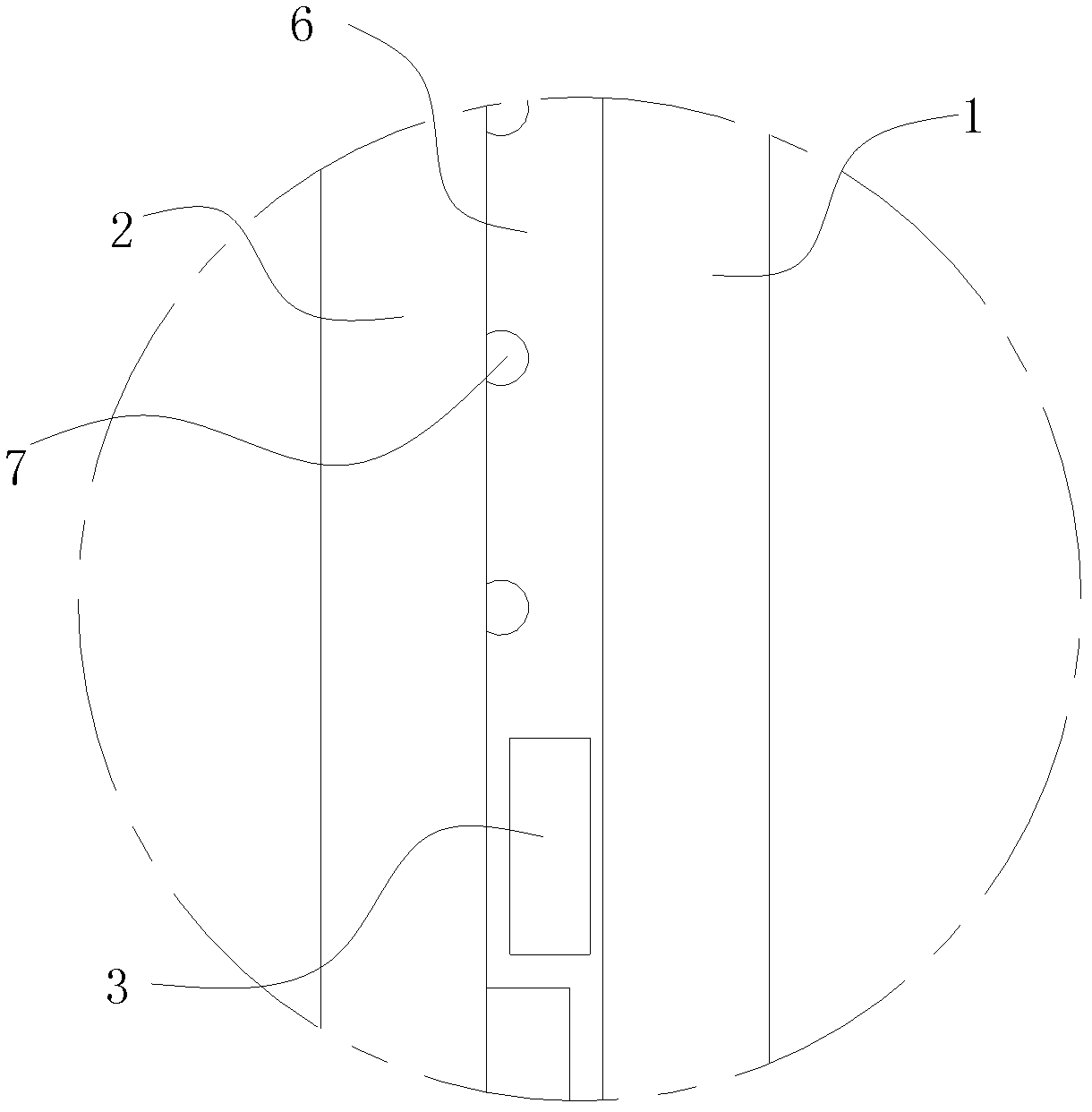

[0021] like Figure 1 to Figure 4 As shown, a capacitive touch screen includes an upper conductive film 1, a lower conductive film 2 and an optical adhesive layer 3, and the optical adhesive layer 3 is arranged between the upper conductive film 1 and the lower conductive film 2; the optical adhesive layer 3 includes an edge Part 4, forming a central void area 5 between the edge portions 4, the upper conductive film 1 and the lower conductive film 2 form a cavity 6 at the position of the central void area 5, and a plurality of insulating support platforms 7 are arranged in the cavity 6 .

[0022] Wherein, the edge portion 4 of the optical adhesive layer 3 is in the shape of a "mouth", the cavity 6 is a sealed structure, and the insulating support platform 7 is fixed to the lower conductive film 2 . The insulating support platforms 7 are uniformly distributed in the hollow area 5 in the middle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com