Manufacturing precision marking system of trademark-based subdividing process section, and use method of manufacturing precision marking system

A marking system, manufacturing technology, applied in the manufacturing precision marking system that subdivides the process area under the grade, label or nameplate, international patent classification G09F display, marking field, can solve the lack of interface with cost and energy consumption, target Inconsistency, inability to meet customer problems, etc., to achieve fine control, reduce production costs, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

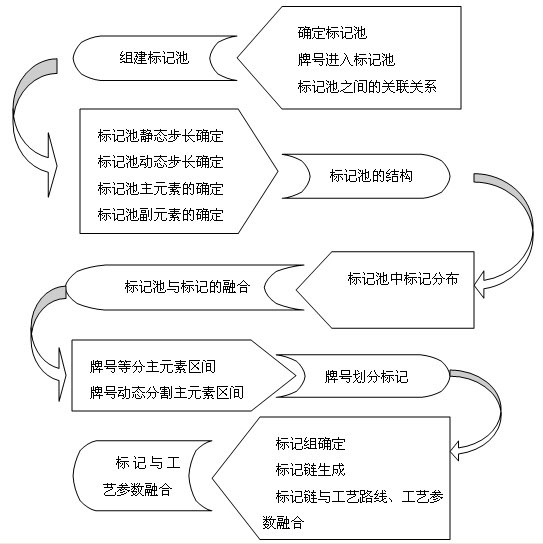

Method used

Image

Examples

Embodiment 1

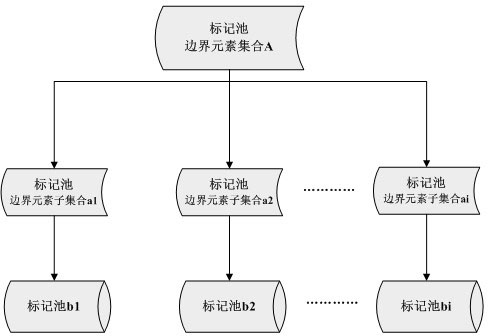

[0048] Embodiment 1: a) Establish or determine the mark pool boundary element set A for generating the mark pool; b) Group the mark pool boundary element set A into several groups of boundary element sub-sets ai; c) Different boundary element sub-sets The set ai establishes the corresponding tag pool bi.

[0049]

[0050] 2 Structural model and algorithm of token pool;

[0051] 1) A model for determining the static step size of the marker pool;

[0052] A) Rule description:

[0053] Using the equal division method, manually determine the value range of the main element and design the number of marks, the maximum is 36, the system calculates the average number, divides the number of marks by the value range of the main element, and obtains the static step size of the mark pool.

[0054] B) Algorithm description:

[0055] Set the lower limit of the main element value range of the tag pool to A1, the upper limit to A2, and the number of tags to N;

[0056] Then the static st...

Embodiment 2

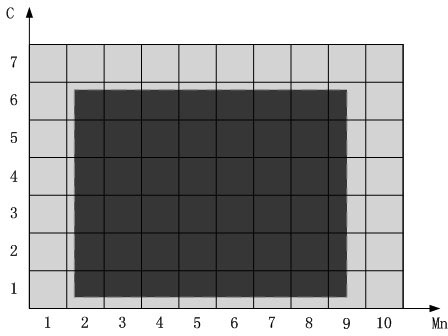

[0091] Example 2: The range of C in the grade is 0.2-6.8, the range of Mn is 1.2-9.5, and the range of the grade may only cover part of some marks.

[0092] 4 The model and algorithm of grade division marking;

[0093] 1) The model and algorithm for equally dividing the main element interval of the grade;

[0094] A) Rule description:

[0095]The grades of some high-end steel grades need to be marked separately according to the grade, instead of generating marks through the above-mentioned mark pool. The algorithm for equally dividing the main element interval is divided into two types: the equal section method and the golden section method. The equal section method is to divide the main element value interval of the brand into 3 sections on average, and the golden section rule is based on the golden section ratio of 0.618. For example, the interval is [0, 10], then the first golden section point is 10×0.618=6.18, and the second golden section point is 10×(1-0.618)=3.82, so ...

Embodiment 3

[0129] Marks and mark groups are marked within a limited range on the X and Y axes of the brand mark; when determining the mark group, it should be ensured that all mark groups cover the entire range of internal control standards, so as to avoid the problem that the process cannot be found after meeting the internal control; along the Y axis The direction marks are divided into 2-5 parts to form 2-5 mark groups, each mark group is set with a representative mark, the representative mark is the mark used in the production organization, and the interval range of the mark group is the target control during production scope.

[0130] That is, for example, the range of C in the grade is 0.0015-0.0085, and the range of Mn is 0.075-0.425; when determining the marking group, it should be ensured that all marking groups cover the entire range of internal control standards, so as to avoid the problem that the internal control cannot be found; Divide C into three parts to form three mark ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap