Extraction needle mechanism of double-station winder

A technology for extracting needles and winding machines, which is applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., and can solve the problems of limited overall structure, uneven force on winding needles, and winding positioning accuracy Low-level problems, to achieve the effect of improving equipment efficiency, saving operating efficiency, and avoiding distraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

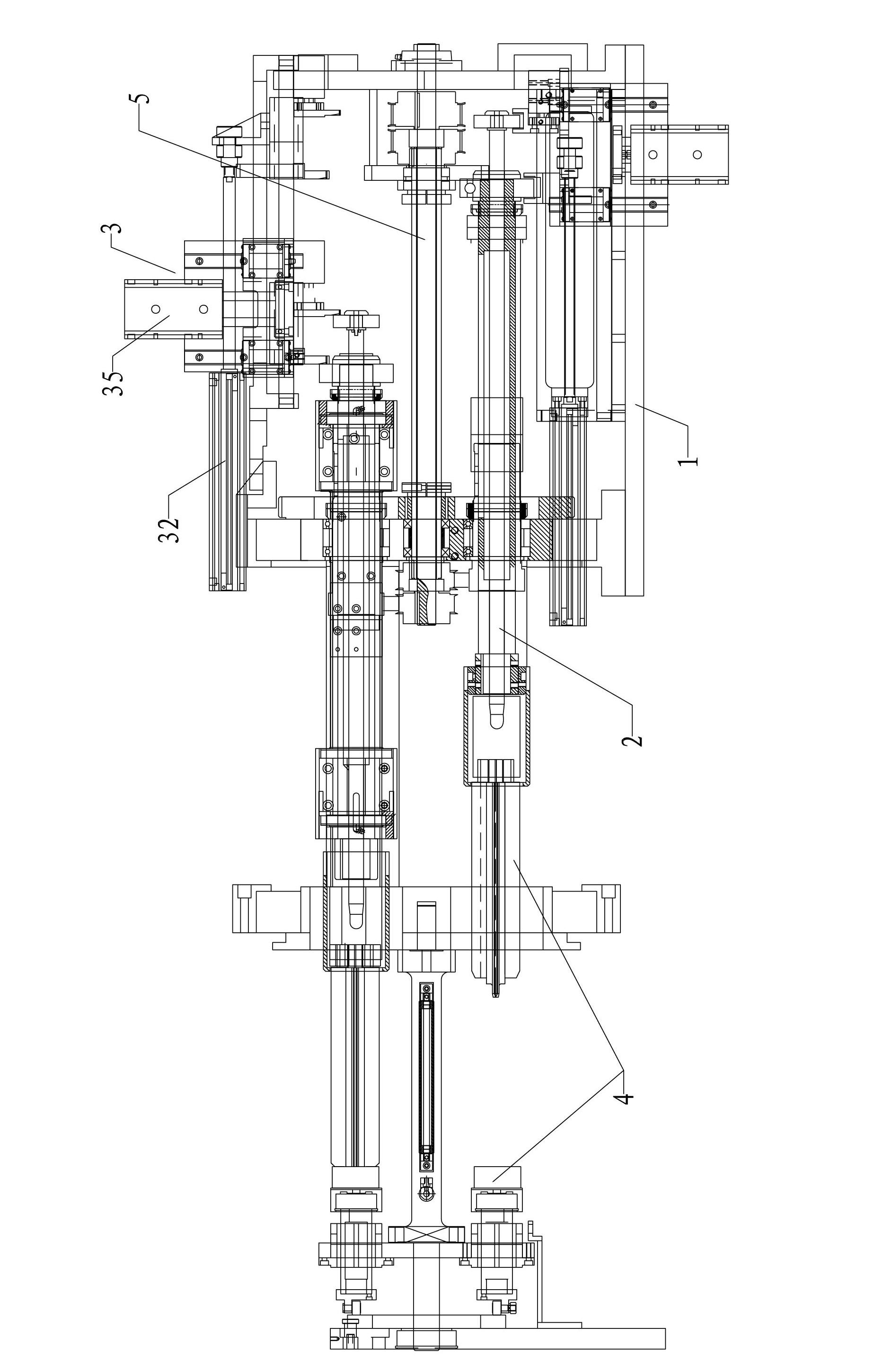

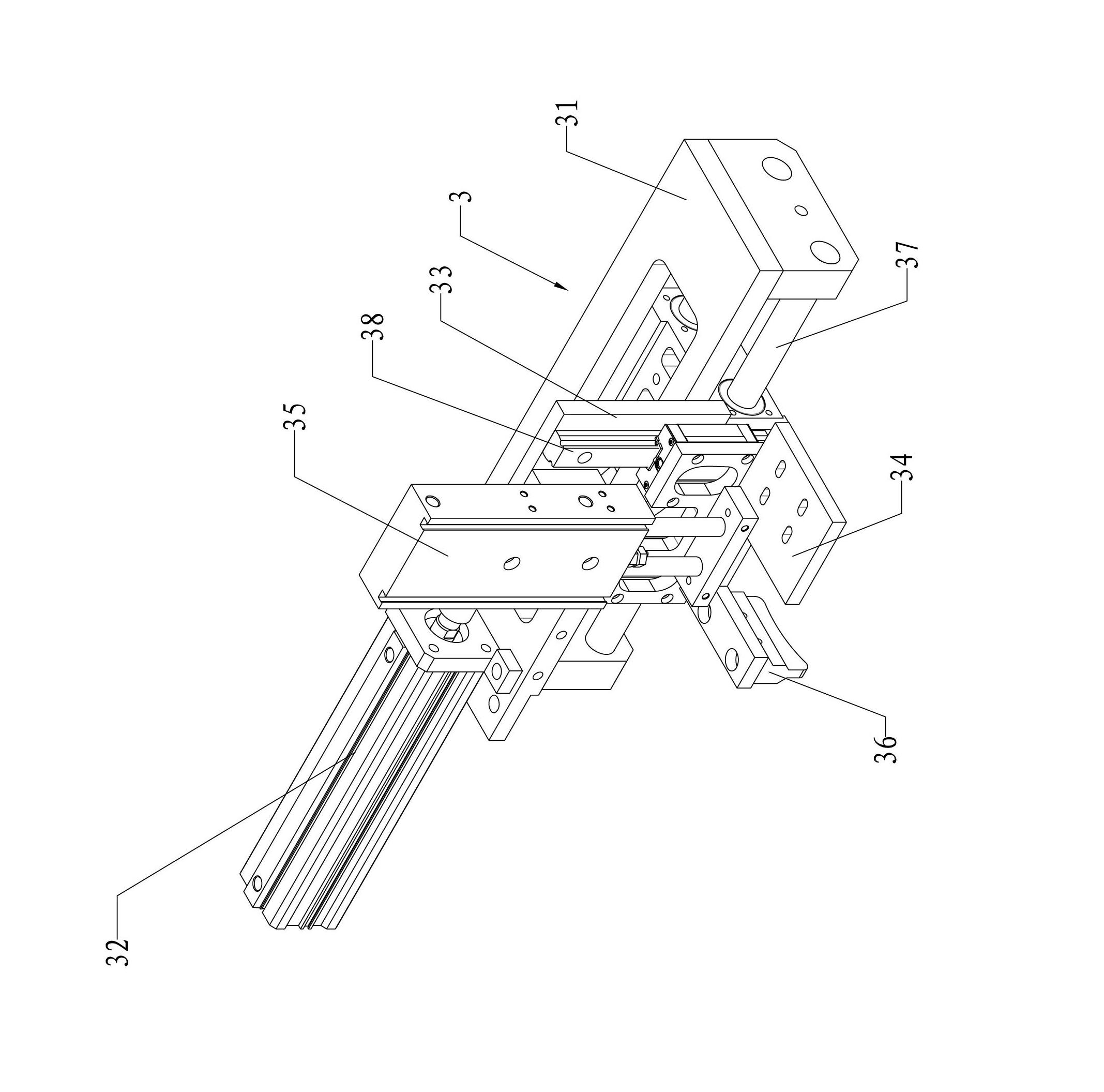

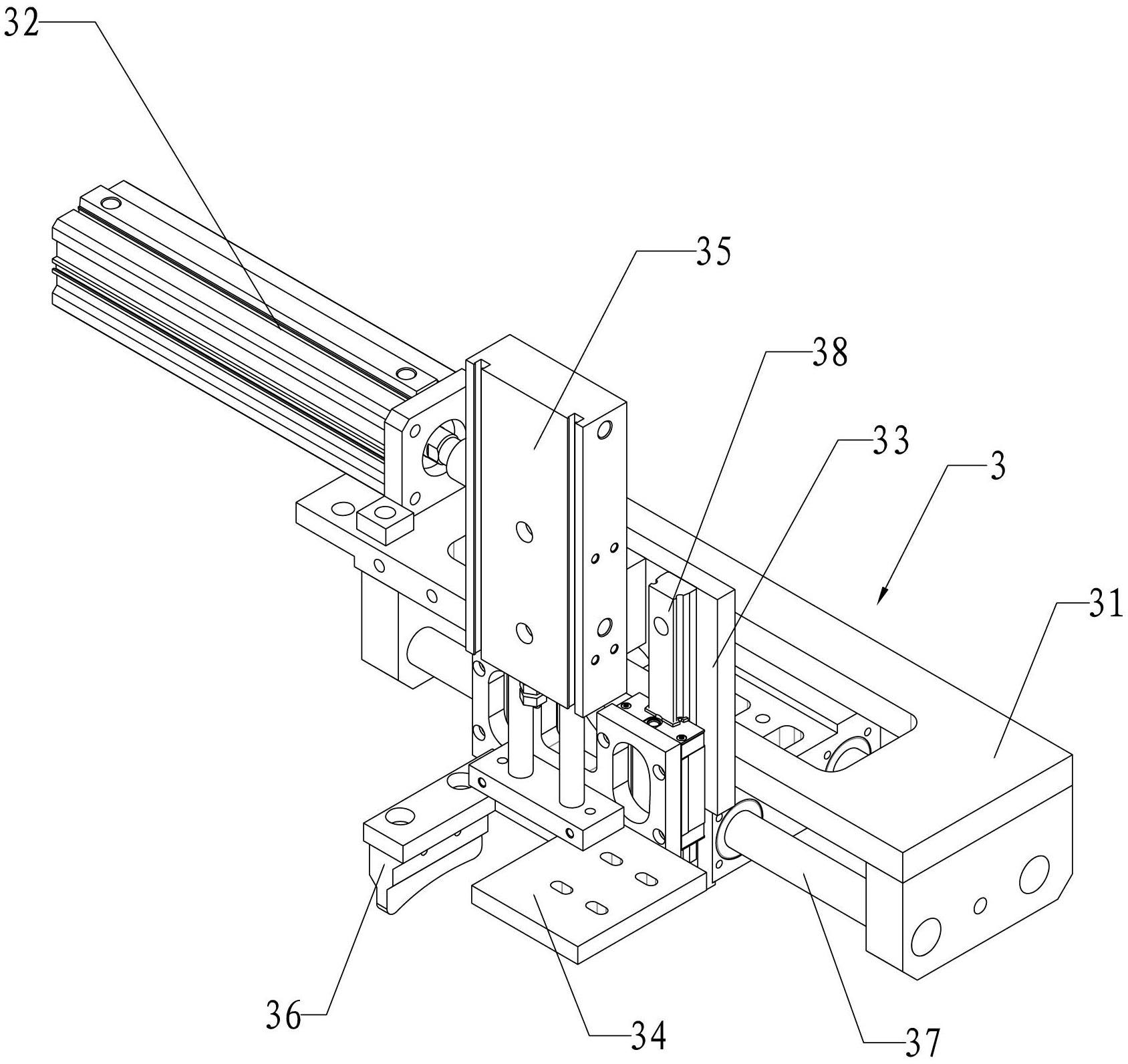

[0019] see figure 1 and attached figure 2 , shown in the accompanying drawing is a needle-drawing mechanism 3 of a double-station winding machine provided in this embodiment, including a frame 1, and the frame 1 is provided with two needle-rolling shafts 2, two needle-rolling shafts 2. It is slidably arranged on the frame 1, and is controlled by the needle withdrawal mechanism 3 arranged on the frame 1. The front ends of the two needle winding shafts 2 are provided with a needle rolling device 4, and the frame 1 is also provided with There is a needle winding shaft drive transmission assembly 5 that controls the rotation of the two needle winding shafts 2 at two stations;

[0020] The needle extraction mechanism 3 includes a fixed frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com