Method and device for manufacturing artificial stone

A technology for preparing device and artificial stone, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of finished product physical properties (strength and fragility, etc.), and achieve the effect of improving wear resistance and pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

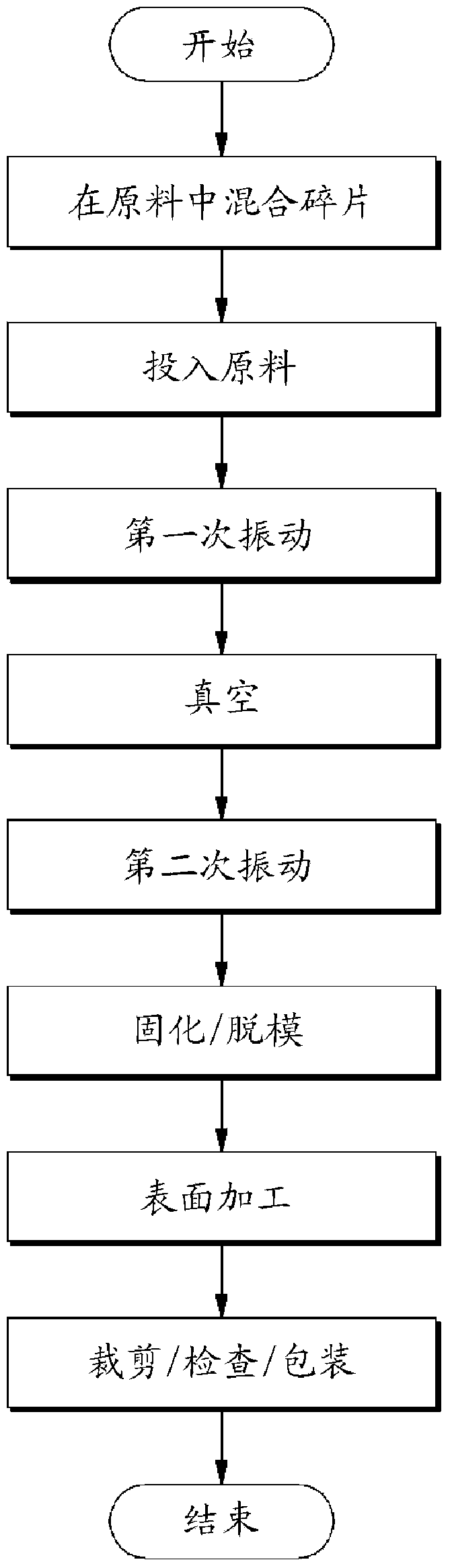

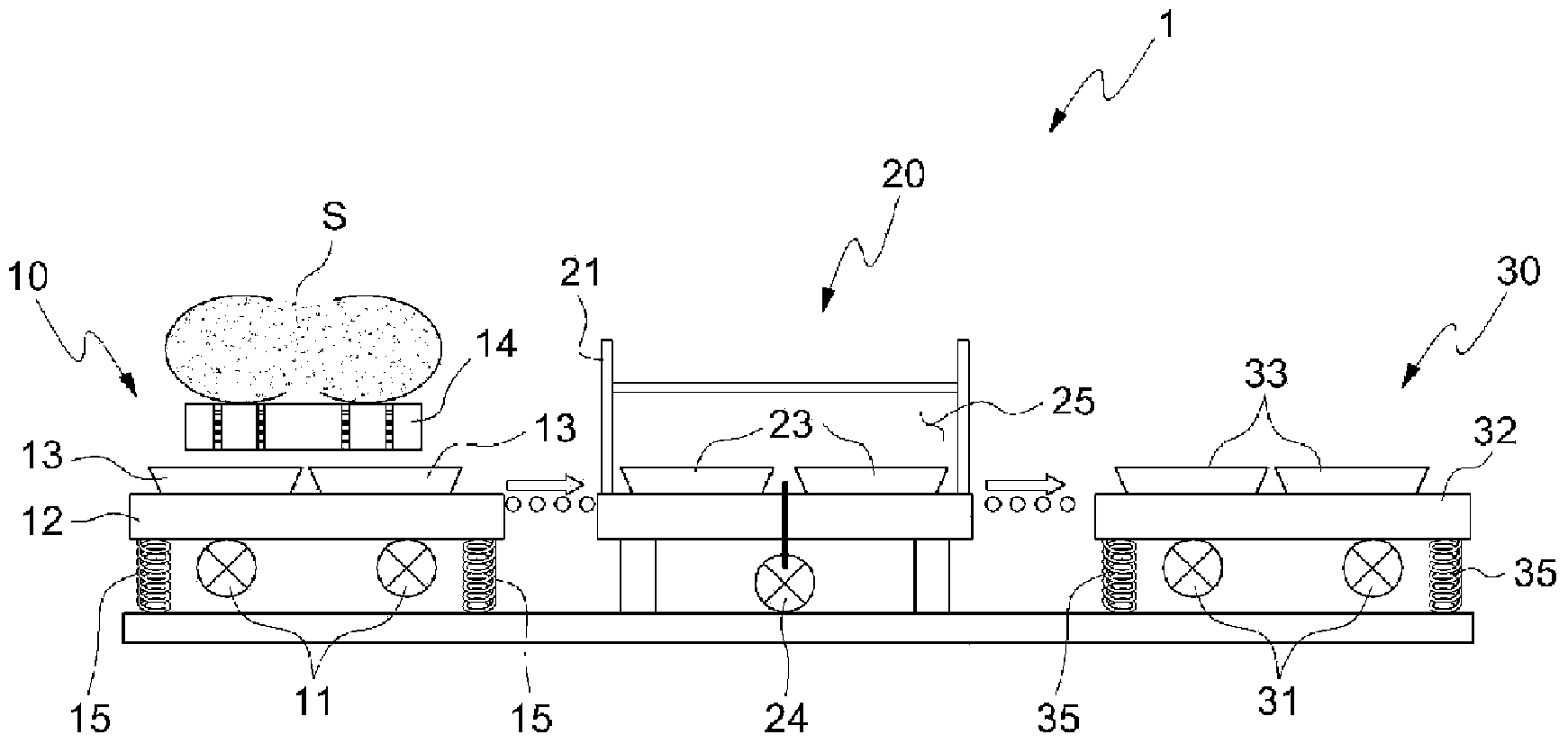

[0016] The preparation method of artificial stone according to an embodiment of the present invention includes the following steps: (a) mixing two or more fragments with different particle sizes in the artificial stone raw material; (b) putting the artificial stone raw material mixed with the fragments into The step of mold; and (c) under normal pressure, using a vibrating device, with a vibration frequency of 1800rpm to 7000rpm, applying vibration for 10 seconds to 1 minute for the first time, so that the raw materials are evenly dispersed in the mold.

[0017] And, the preparation method of artificial stone also includes the following steps: (d) in order to remove the air bubbles of the raw material, under the vacuum condition of 30mmHg or more, apply a vacuum for 10 seconds to 30 seconds; and (e) under normal pressure, Using a vibrating device, at a vibration frequency of 1800rpm to 7000rpm, applying vibration for a second time for 30 seconds to 5 minutes to shape the artifi...

Embodiment

[0044] Cement-like artificial stones were prepared using natural stone fragments.

[0045] First, cement slurry as a binder of the artificial stone is put into a mold. At this time, the cement slurry used contains about 150 parts by weight of natural stone chips of about 5 mm in size, about 100 parts by weight of natural stone chips of about 2 mm in size, and about 50 parts by weight of cement for 100 parts by weight of cement. natural stone powder, about 30 parts by weight of water and about 2 parts by weight of plasticizer.

[0046] After putting the cement slurry into the mold, use the vibrating device to apply vibration for about 15 seconds for the first time to spread the cement slurry with a specified thickness. After the mold is put into the vacuum chamber and apply a vacuum for about 25 seconds to remove the inside of the slurry bubbles. After that, re-use the vibrating device to apply vibration to the mold for the second time for about 3 minutes, so that the natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com