Method and device for producing molded trim parts

A decorative part and molding technology, applied in the field of manufacturing molded decorative parts, can solve problems such as adverse economic effects, and achieve the effect of high dimensional accuracy and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

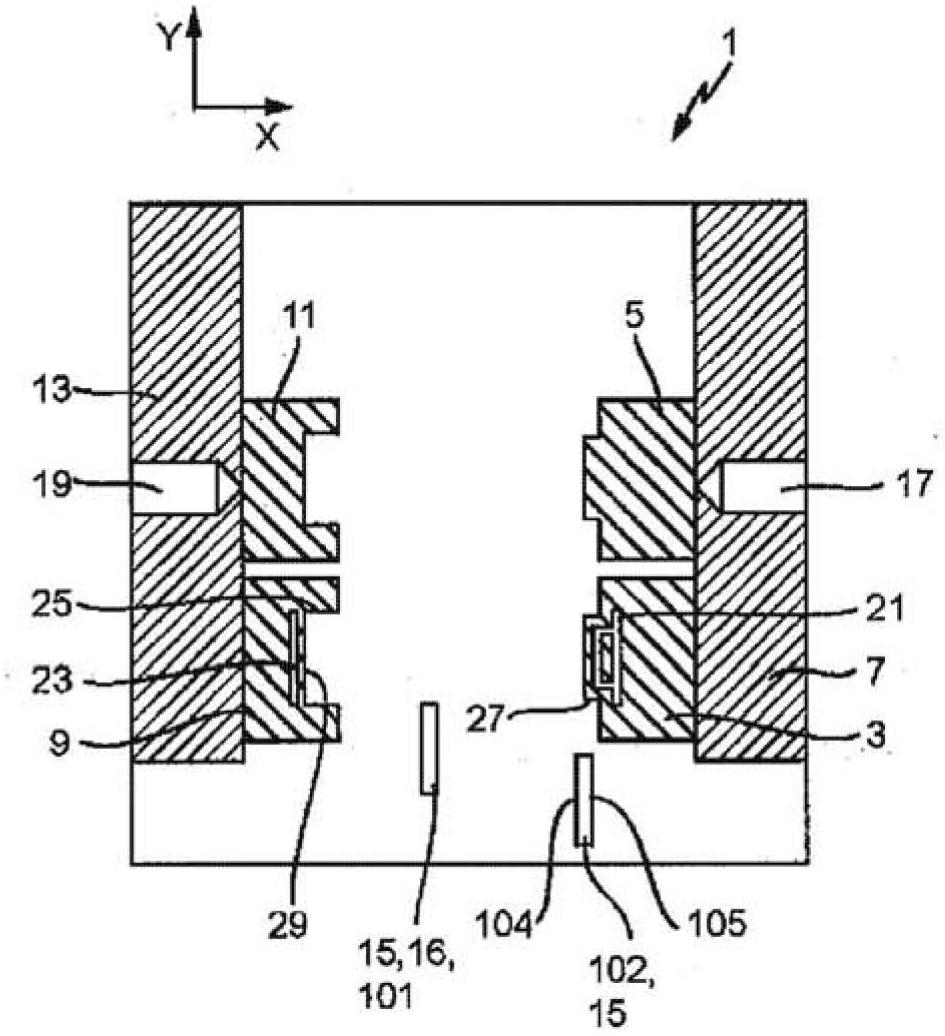

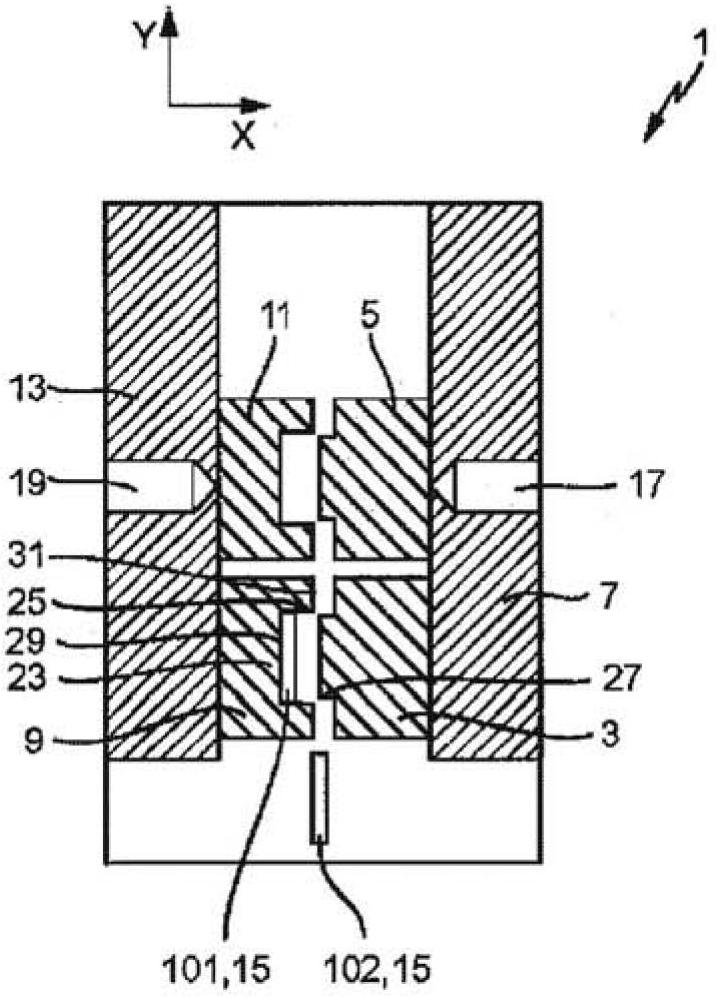

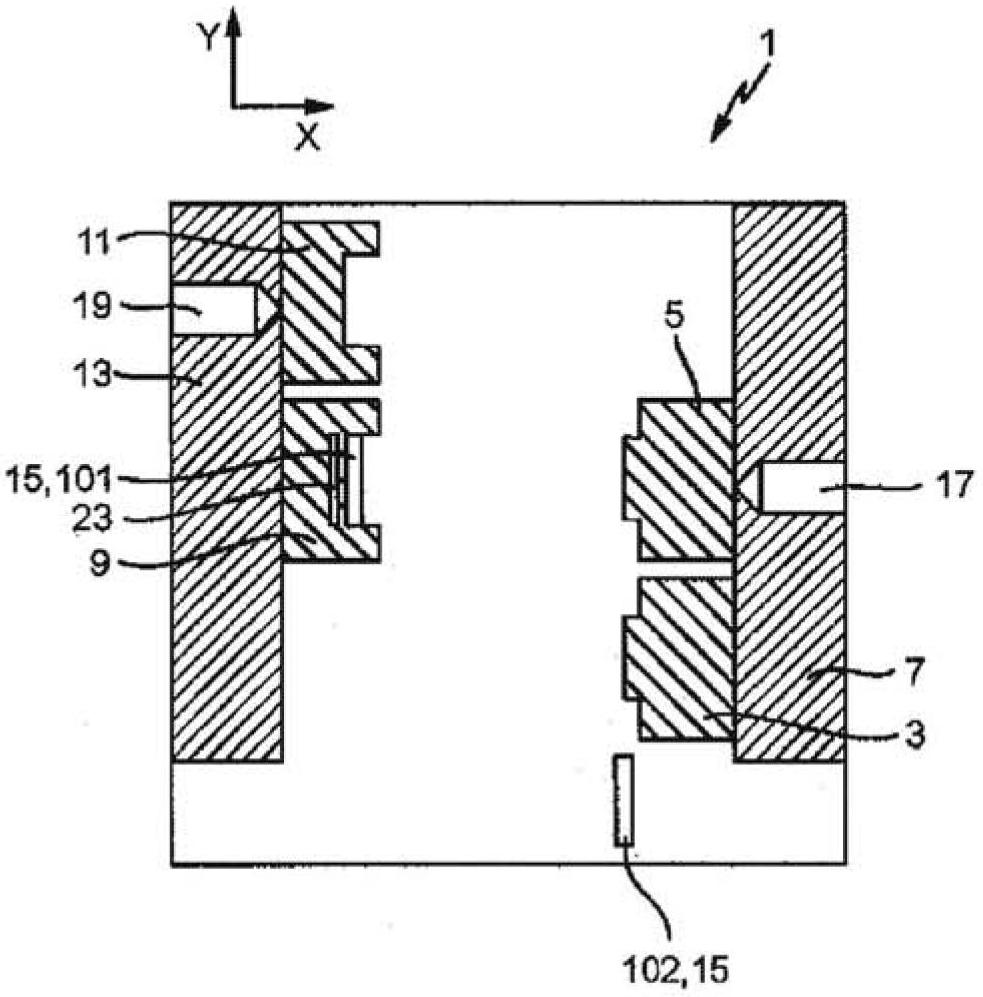

[0047] exist figure 1 The device 1 according to the invention shown in the figure has a pressing die 3 and an injection die 5 , which are arranged immovably on a common frame 7 . The device 1 also has a first die 9 and a second die 11 which are arranged side by side on a support 13 . The bearing 13 is movable relative to the frame 7 along the axes X and Y. The movement of the support 13 relative to the frame 7 then moves the two dies 9 , 11 in parallel relative to the dies 3 , 5 .

[0048] exist figure 1 , the support 13 is spaced apart from the frame 7 along the axis X in such a way that a decorative blank 16 can be inserted as a decorative workpiece 15 between the punches 3, 5 and the dies 9, 11—the device is thus in the open position . In addition, the position of the support 13 along the Y axis is selected such that the first die 9 lies opposite the pressing die 3 along the X axis and is assigned to it—the device 1 is in the pressing position.

[0049] For the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com