Sensible heat recovery device with ash capture for preventing slag bonding and staining

A sensible heat recovery and anti-slagging technology, which is applied in steam condensation, lighting and heating equipment, combustion methods, etc., can solve the problems of reducing overall efficiency, reducing the energy quality of syngas, and improving system operating costs, so as to improve heat transfer The effect of low effect, ash melting point and sodium potassium salt content, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

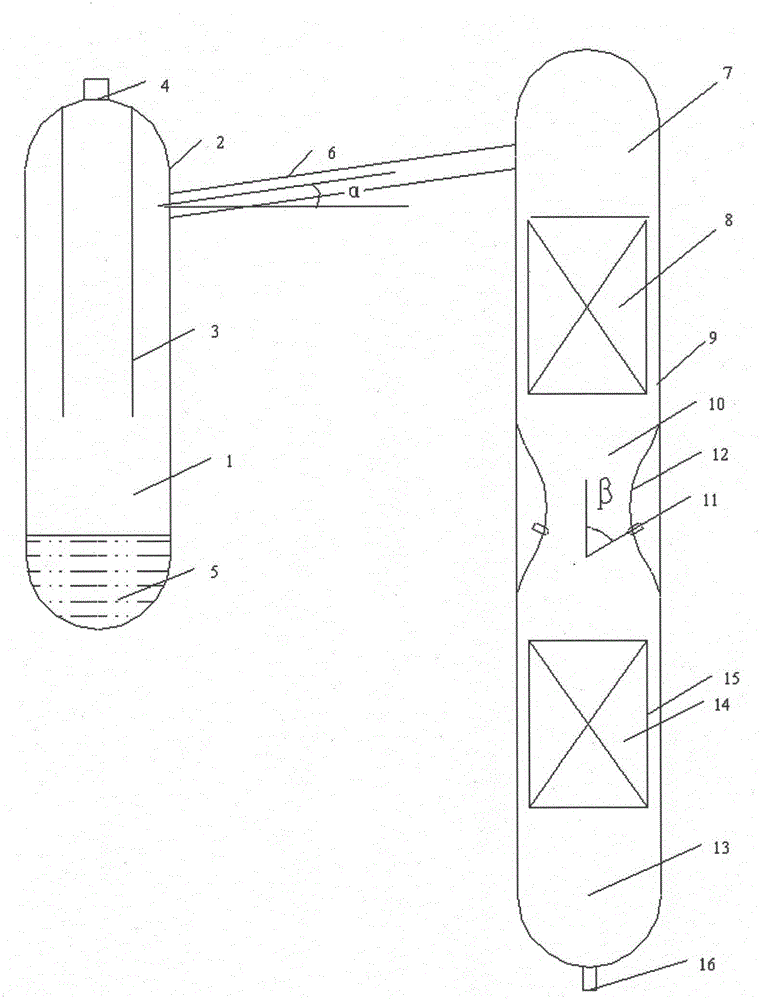

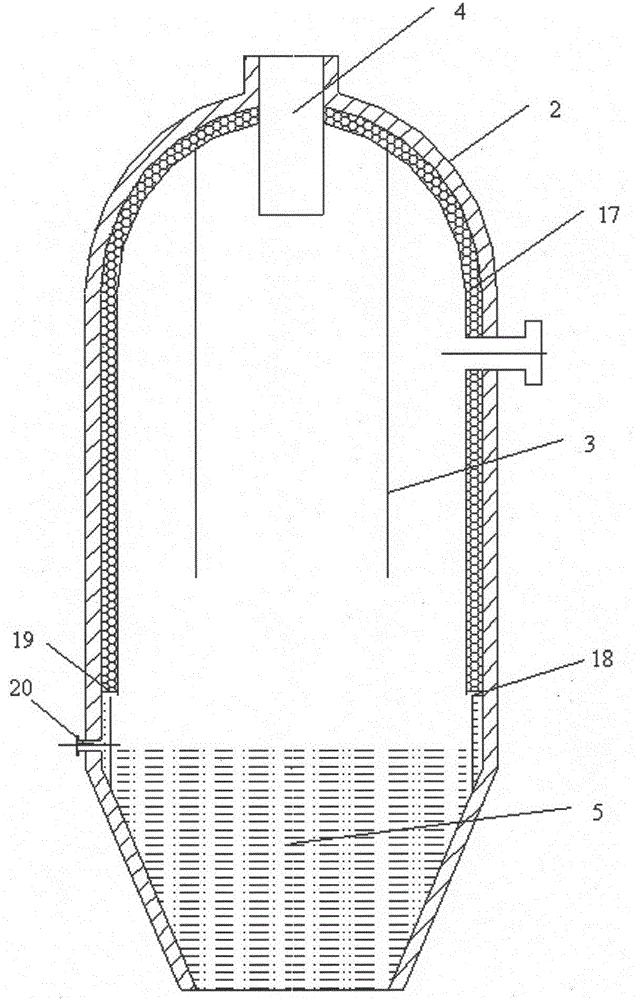

[0037] A dry powder gasifier with a daily processing capacity of 3,000 tons of coal has a gasification pressure of 4.0 MPa, the temperature at the inlet of the slagging chamber after gasification of the syngas is 1300°C, and the total gas flow out of the gasification chamber is 26,706 Nm3 / h. The inner diameter of the slag collection chamber is 3.6m, and the inner diameter of the slag catcher 3 is 2.5m. The slag catcher is made of high-temperature resistant alloy steel with a heat-resistant coating material on the surface. The guide chamber 7, the radiation heating surface 8 adopts a three-layer membrane water-cooled wall structure, the gas outlet temperature is 780°C, and the gas temperature after cooling by the quenching section 10 is 530°C, and the convection heating surface 14 adopts a membrane-type coil water-cooled wall structure, Gas outlet 260°C. The coal quality analysis is shown in the table below:

[0038] name

Embodiment 2

[0040] A dry powder gasifier with a daily processing capacity of 3,000 tons of coal has a gasification pressure of 4.0 MPa, the inlet temperature of the slagging chamber after gasification of the syngas is 1400°C, and the total amount of gasification of the syngas is 27,402 Nm3 / h. The inner diameter of the slag collection chamber is 3.7m, and the inner diameter of the slag catcher 3 is 2.5m. The slag catcher is made of high-temperature resistant alloy steel with a heat-resistant coating material on the surface. The guide chamber 7, the radiation heating surface 8 adopts a single-layer membrane water wall structure, the gas outlet temperature is 730°C, the chilling section does not use chilling gas, and directly enters the convection heating surface 14, and the convection heating surface 14 adopts membrane coil water cooling Wall structure, gas outlet 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com