Steel billet tilting gear

A steel turning machine and steel billet technology, applied in the field of steel billet turning machine, can solve the problems of high cost and complex structure, and achieve the effect of low cost, simple and compact structure, and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

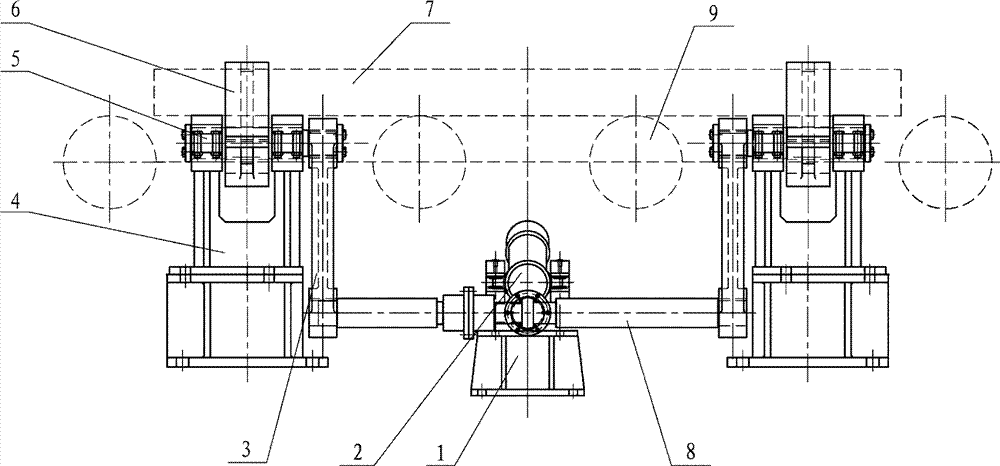

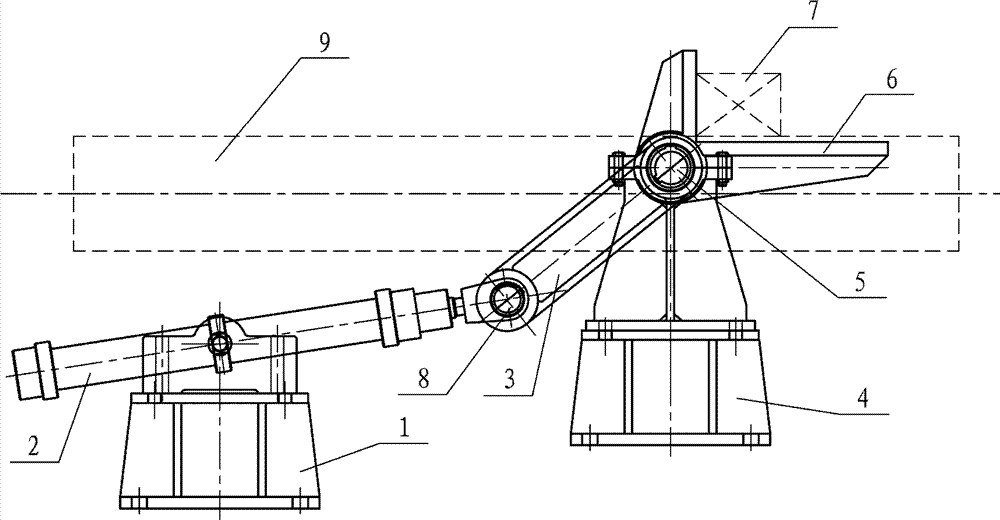

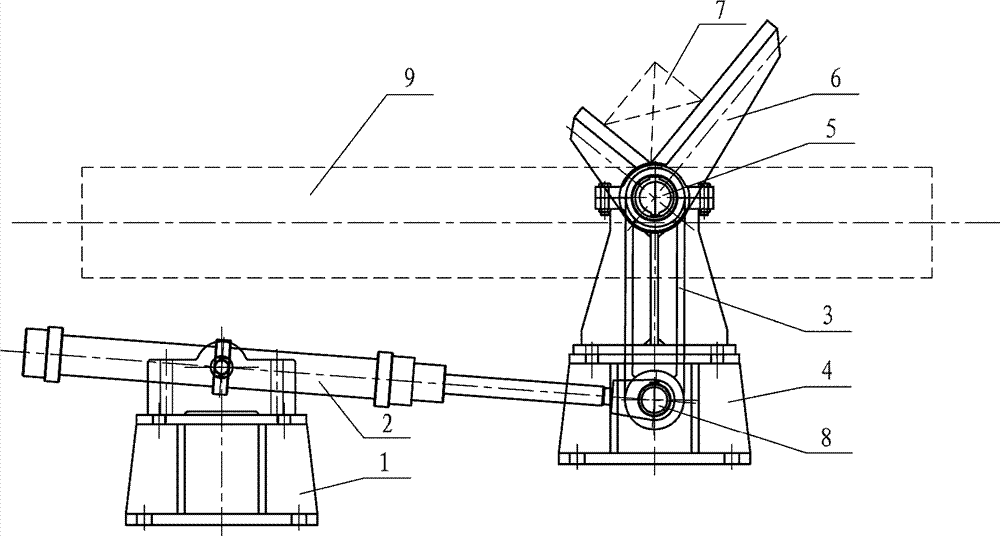

[0029] figure 1 is a front view showing a billet turner according to an embodiment of the present invention.

[0030] Such as figure 1 As shown, the steel billet turning machine according to the embodiment of the present invention mainly includes: a driving device including a first support 1 and a linear motion linear mechanism 2, the first support 1 is used to support the linear motion actuator 2; the steel turning device , including a second bearing 4, a rotating shaft 5 and a finger 6, the rotating shaft 5 is installed on the top of the second bearing 4 and is supported by the second bearing 4 for its rotation, and the finger 6 is fixedly installed on the rotating shaft 5, when the rotating shaft When 5 rotates, the claw 6 rotates together with the rotating shaft 5; the connecting rod assembly is connected between the rotating shaft 5 and the hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com