Assembly method of radiator and device applying method

An assembly method and radiator technology, which are applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of destroying assembly accuracy and assembly consistency, labor intensity of staff, and difficulty in balancing assembly, and achieve assembly methods. Quick and convenient, fast and convenient pipe routing operation, high-efficiency assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

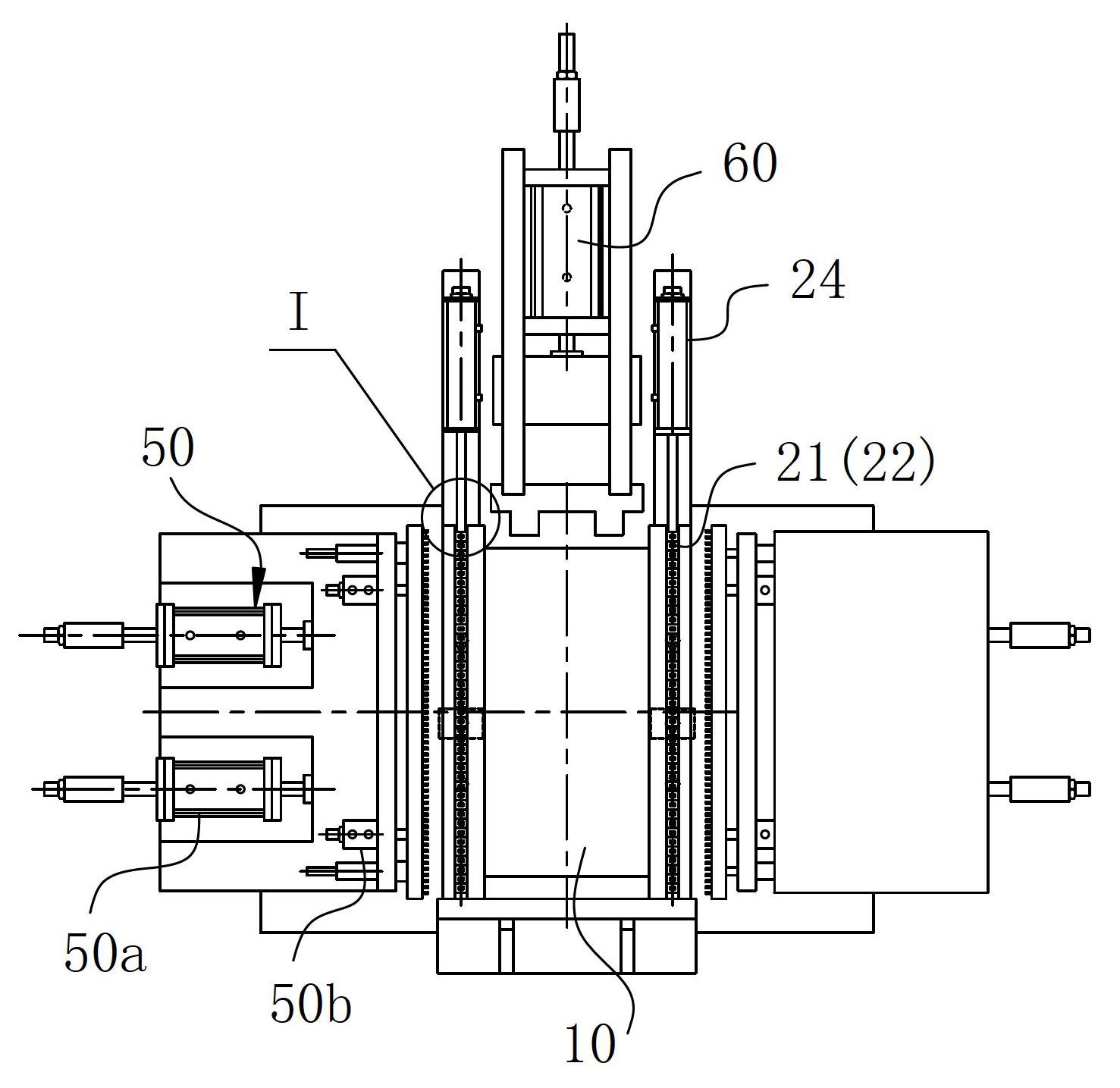

[0019] A method for assembling a radiator, comprising the following steps:

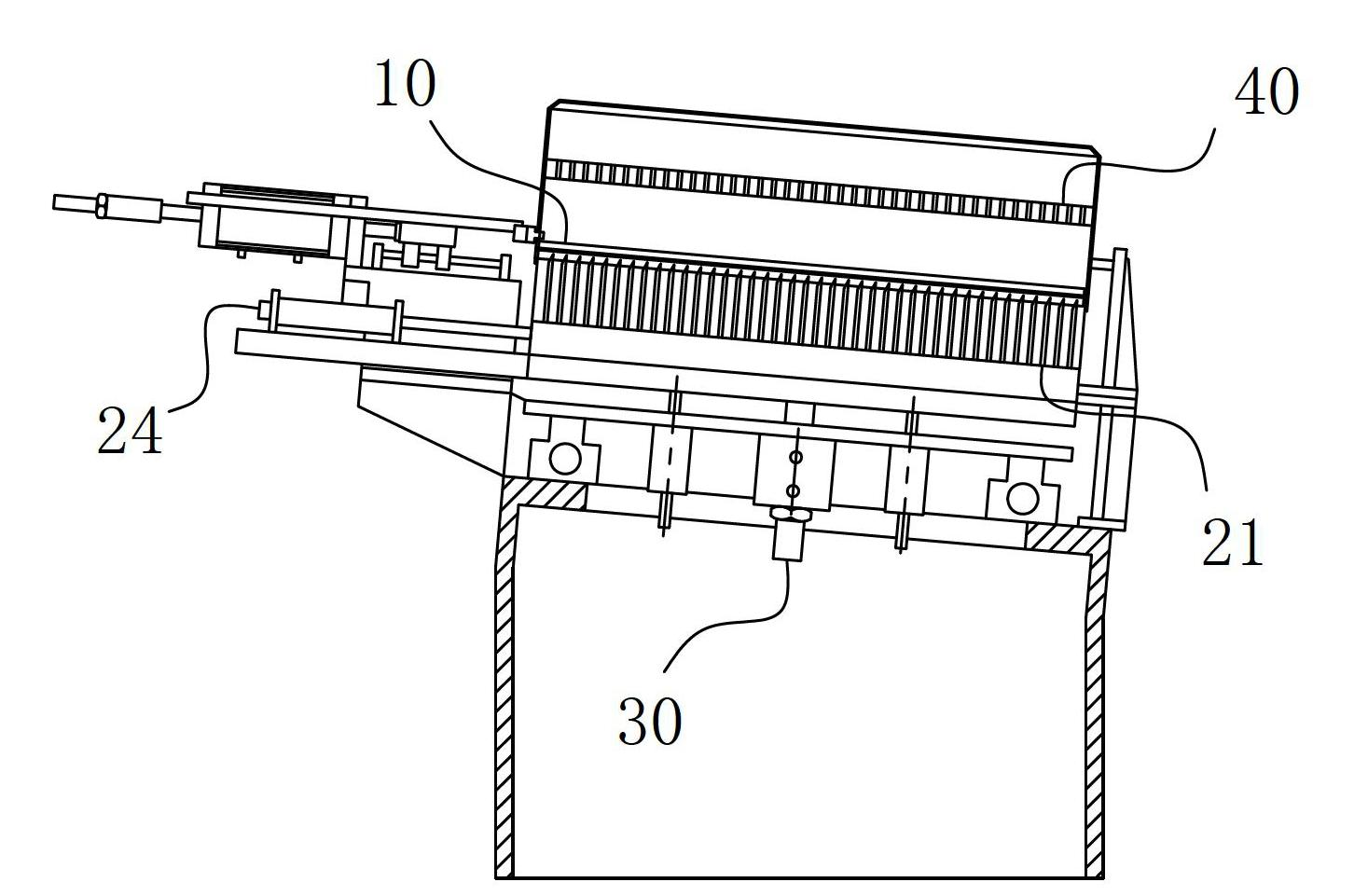

[0020] (1) Set up the working platform 10, and arrange the cooling pipes evenly on the working platform 10;

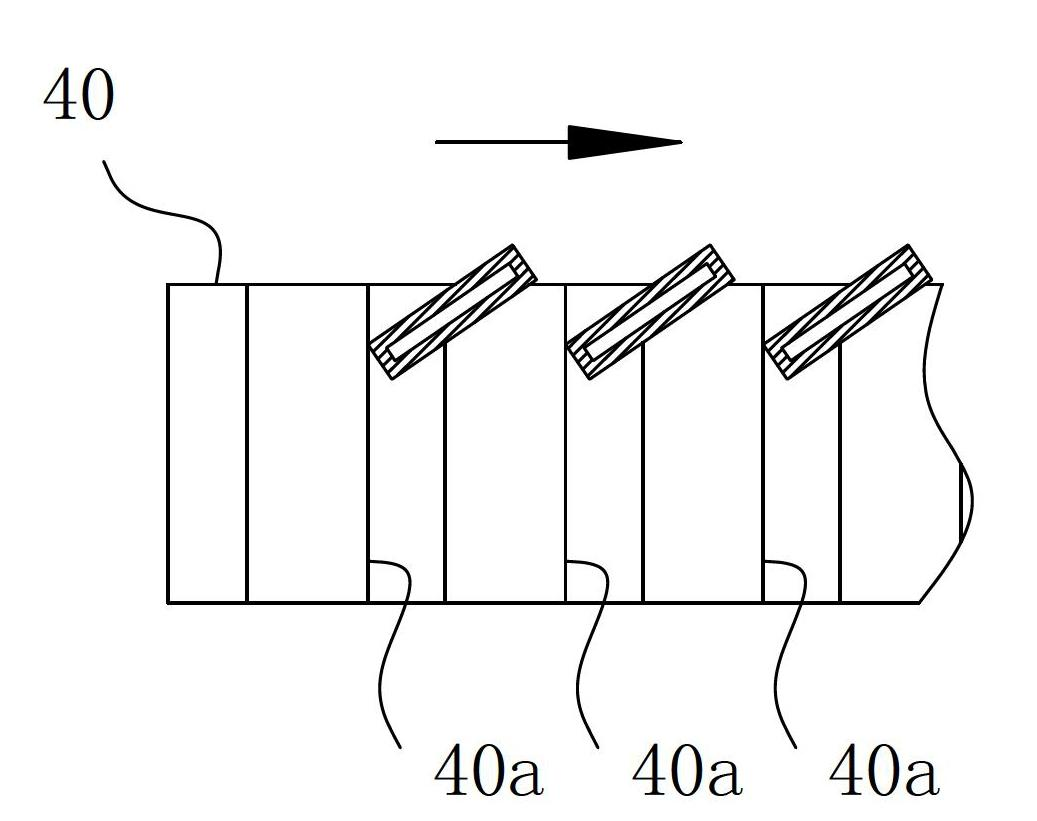

[0021] (2) Place a heat dissipation strip in the gap between the heat dissipation pipes;

[0022] (3) Install splints on both sides of the assembly composed of heat dissipation pipes and heat dissipation strips, and clamp the heat dissipation pipes, heat dissipation strips and splints;

[0023] (4) Install fixing plates at both ends of the heat dissipation pipe and the heat dissipation strip to complete the assembly process.

[0024] In step (1), the distance between the heat pipes is greater than or equal to the width of the heat dissipation belt in a straight state; at the same time, guide grooves are arranged above the working platform 10, and the guiding paths of the guide grooves are located on the fixing ports of the heat pipes on the working platform 10. First, the whole group or part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com