A visual recognition device and method suitable for placement machines

A technology of visual recognition and placement machine, which is applied in the direction of assembling printed circuits, printed circuits, and electrical components with electrical components. Efficiency, accurate and fast component placement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

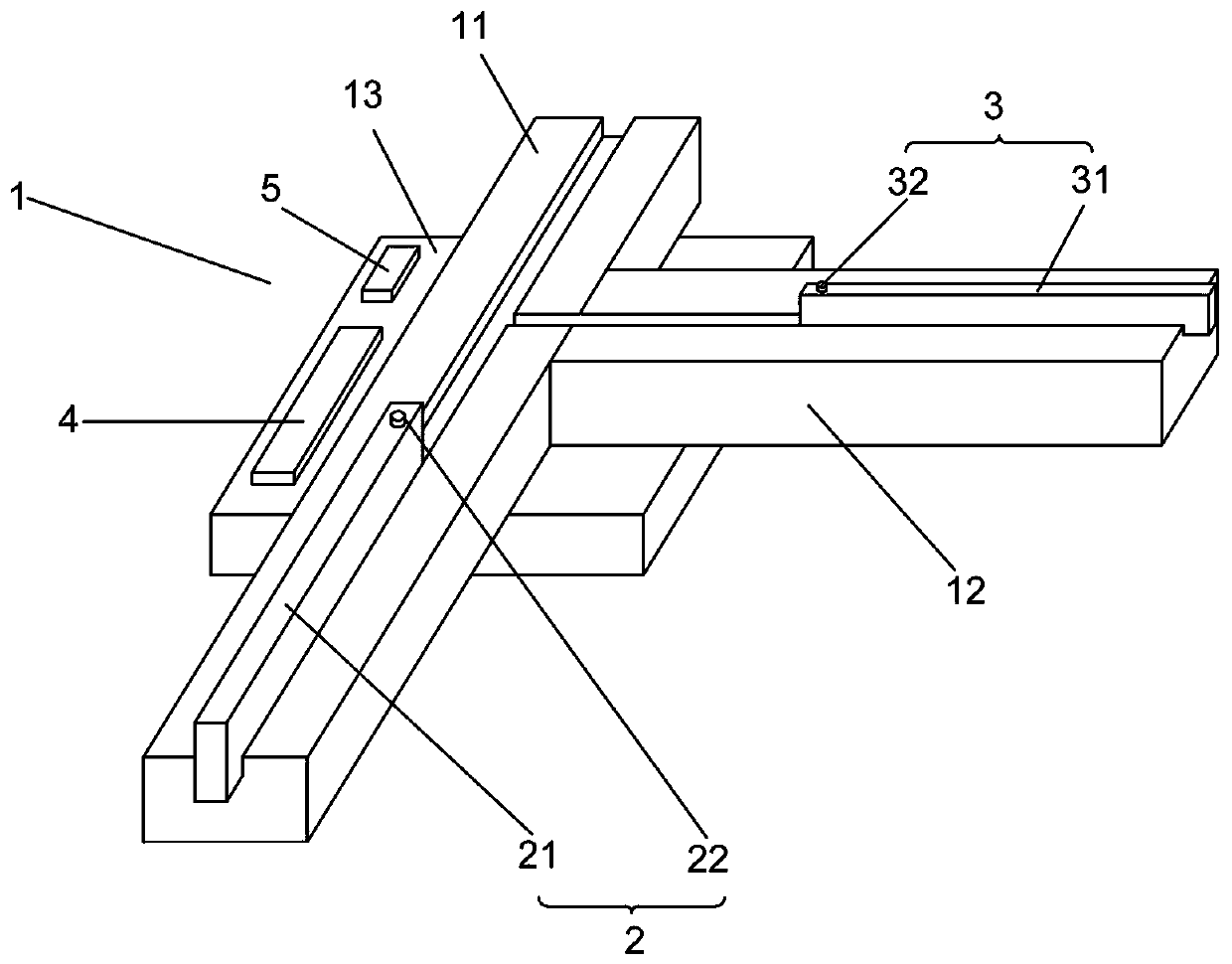

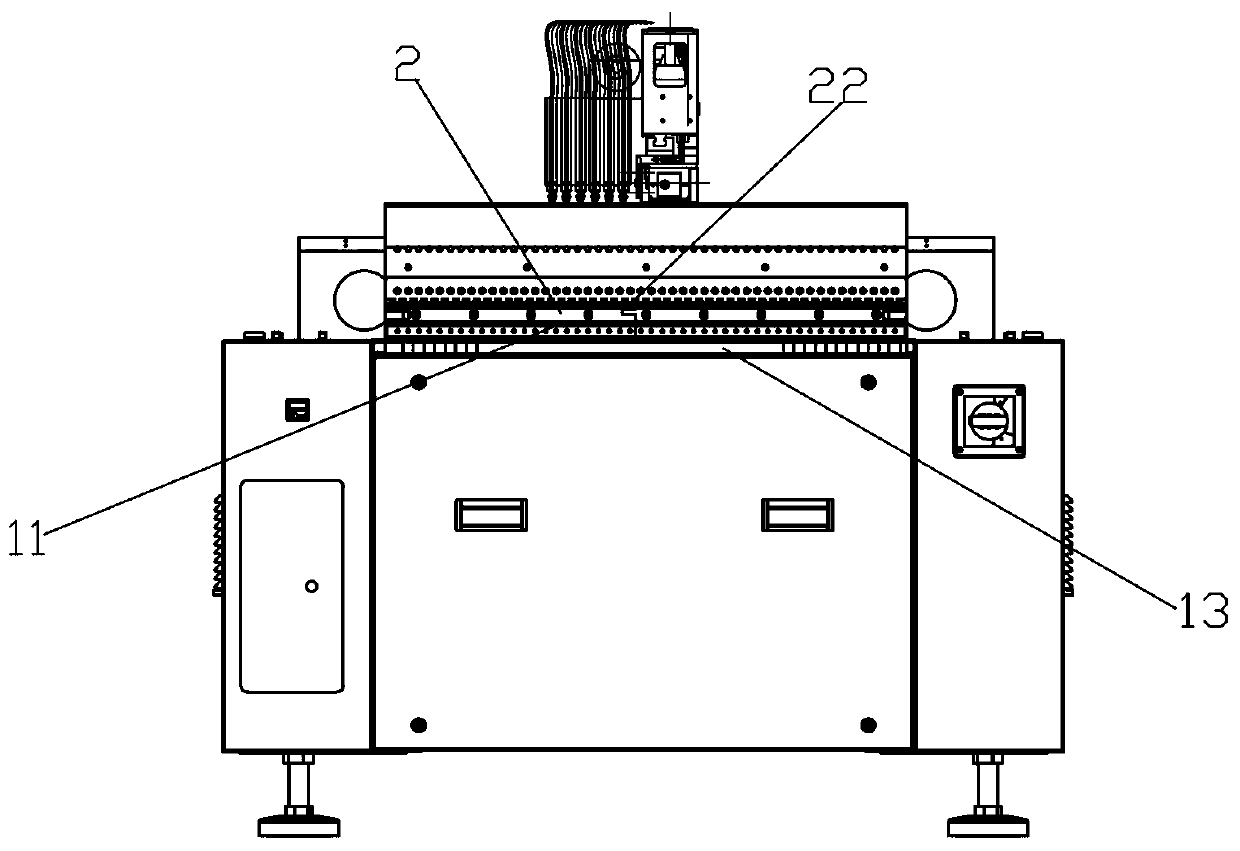

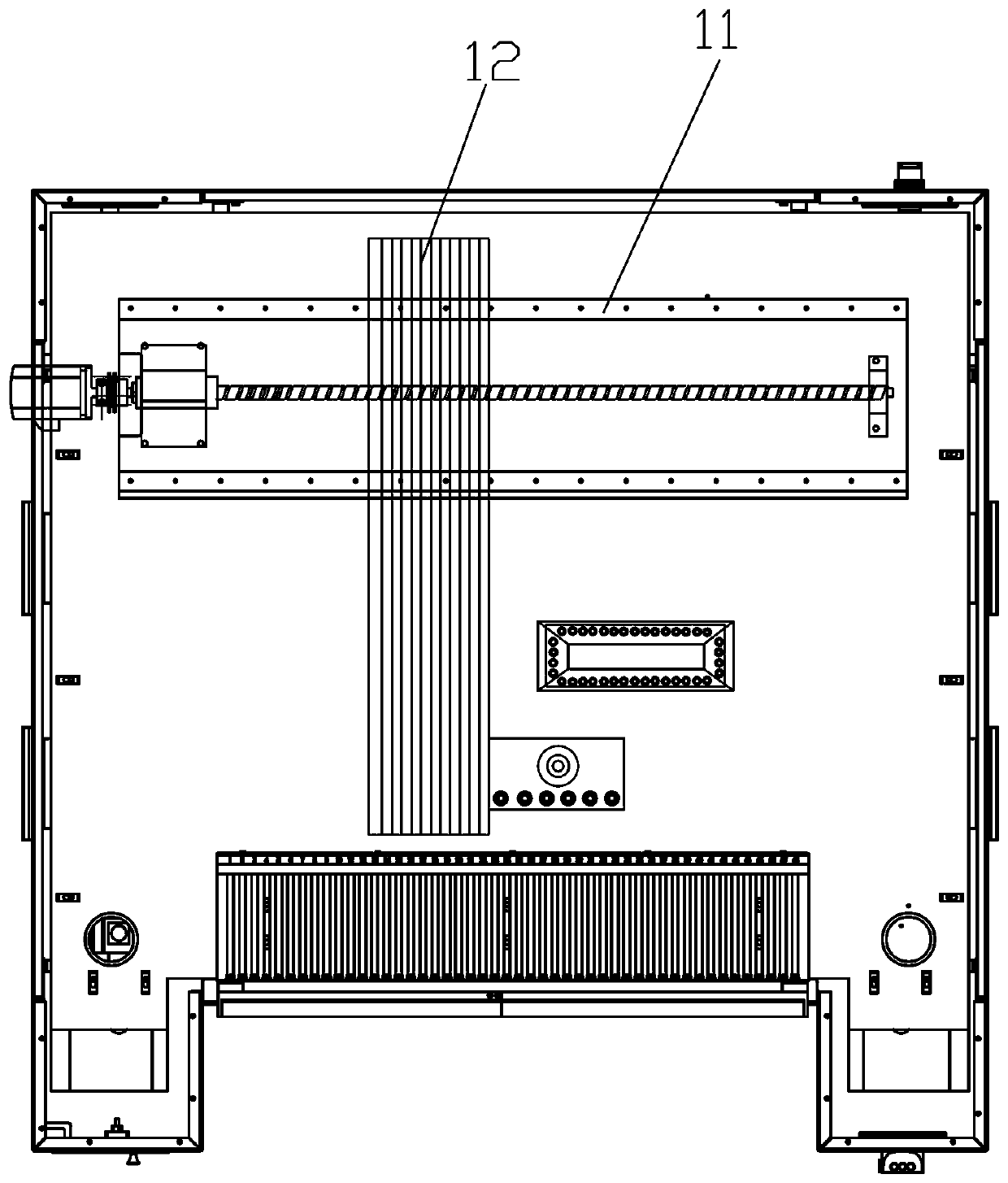

[0040] Example one: such as Figure 1 to 3 As shown, it is only one of the embodiments of the present invention. In order to achieve the effect of better visual recognition of the position of the component, a visual recognition device suitable for placement machine is proposed, which includes a placement channel 1, a component transmission part 2 and a material The transfer part 3, the patch channel 1 is provided with a first transfer rail 11, a second transfer rail 12, and a patch cavity 13 provided at the junction of the first transfer rail 11 and the second transfer rail 12. The patch channel 1 is provided with a magnetic member 4 and a calculation unit 5. The component transmission part 2 includes a first sliding rod 21 extending along the extension direction of the first transmission rail 11 and a first sliding rod 21 arranged on the first sliding rod 21 The first magnetic induction member 22, the material transport portion 3 includes a second sliding rod 31 extending alon...

Embodiment 2

[0050] Embodiment two: such as Figure 4 Shown is only one of the embodiments of the present invention. In order to facilitate the understanding of a visual recognition device suitable for placement machines, the present invention provides a visual recognition method suitable for placement machines. A feeding management device suitable for placement machines. The device includes a placement channel, a component transmission part and a material transmission part. The method includes the following steps:

[0051] S1: Set the first magnetic induction part on the first sliding rod of the element transmission part, and set the second magnetic induction part on the second sliding rod of the material transmission part to ensure that both the first magnetic induction part and the second magnetic induction part are located on the patch channel. Within the magnetic field range;

[0052] It is ensured that the first magnetic induction element and the second magnetic induction element move in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com