General accurate grinding clamp with adjustable sluice valve flashboard

A gate and fine grinding technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of cumbersome, many specifications of wedge gate valves, and lack of versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

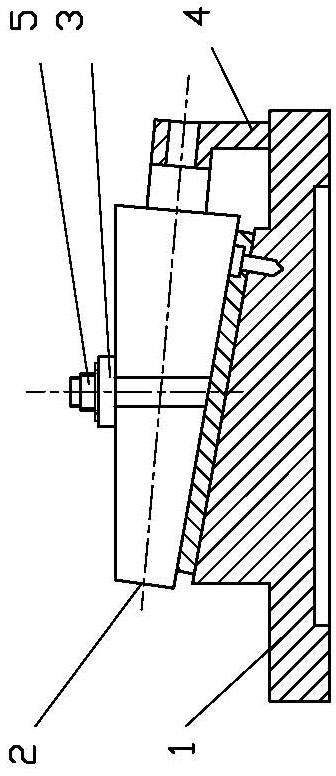

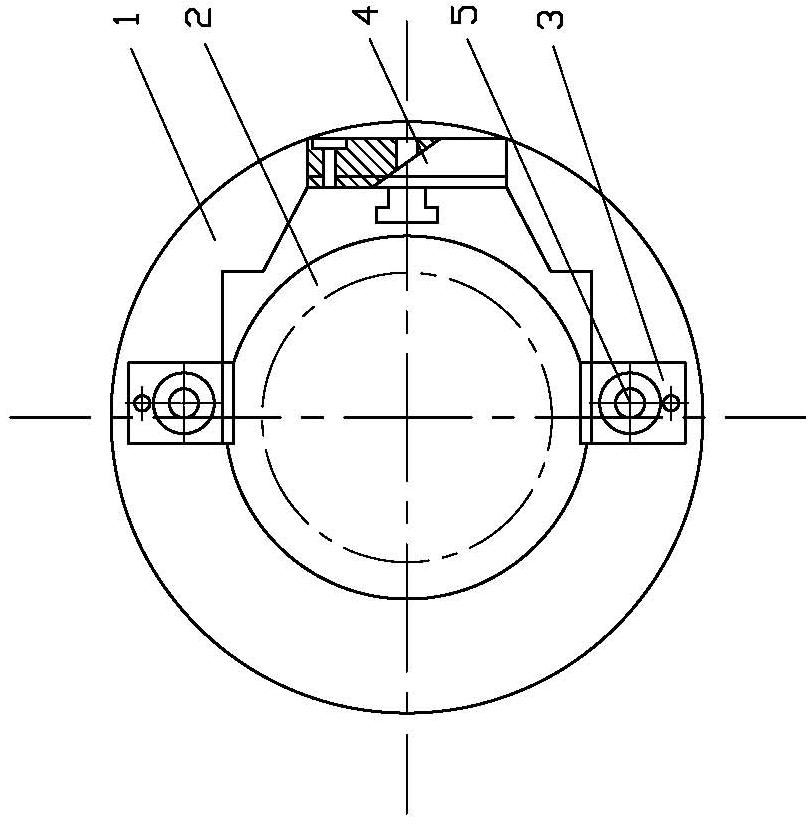

[0019] The basic structure of the universal fine grinding jig with adjustable gate valve plate in this embodiment is as follows: image 3 and Figure 4 As shown, it includes a disc-shaped wedge-angle inclined formwork 1 with a workpiece 2 placed on the upper surface. The upper surface of one end of the wedge-angle inclined formwork is fixed with a baffle plate 4 for workpiece positioning, and the upper surface of the other two sides is provided with a large bottom and a small upper surface. T-shaped sliding groove, in which the lower end of the inverted compression bolt 5 is installed to form a moving pair. The upper end of the compression bolt 5 is screwed to press the nut of the pressure plate 3, so the compression bolt can be adjusted according to the size of the workpiece. Move the position in the groove, so as to meet the clamping needs of different specifications of the gate. In addition, the lower surface of one end of the wedge-angle inclined formwork 1 fixing the ba...

Embodiment 2

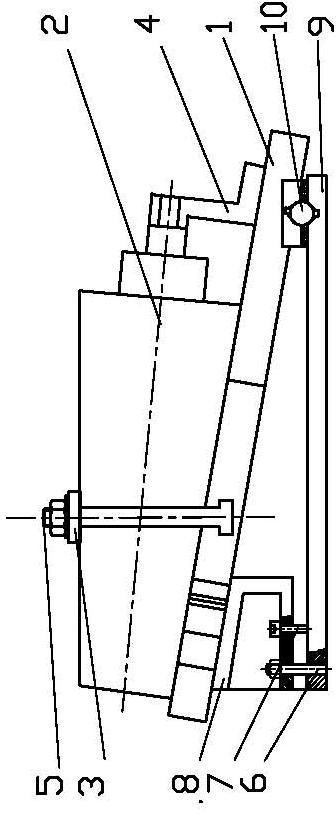

[0021] The specific structure of the adjustable universal fine grinding jig of the gate valve gate plate in this embodiment is as follows: Figure 5 and Figure 6 As shown, the basic structure is similar to that of Embodiment 1. The lower surface of one end of the wedge angle inclined formwork 1 fixed baffle plate 4 is embedded with a fixed hinge block 1-1, and the corresponding positions of the lower surface of the hinge block 1-1 and the upper surface of the bottom plate 9 are respectively It has V-shaped grooves with opposite openings, and hinge pins 10 are installed in the two V-shaped grooves, thereby forming a hinged connection structure between one end of the wedge-angle inclined formwork 1 and the bottom plate 9 .

[0022] In addition, this embodiment is improved on the basis of Embodiment 1. The upper surfaces of both sides of the wedge-angle inclined formwork 1 and the connection between the bottom plate 9 and the compression bolt 7 are respectively provided with ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com