Hoisting tool for electric torque spanner

A torque wrench, electric technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of unfavorable work efficiency, waste of materials, physical exertion, etc., and achieve the effect of benefiting work efficiency, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

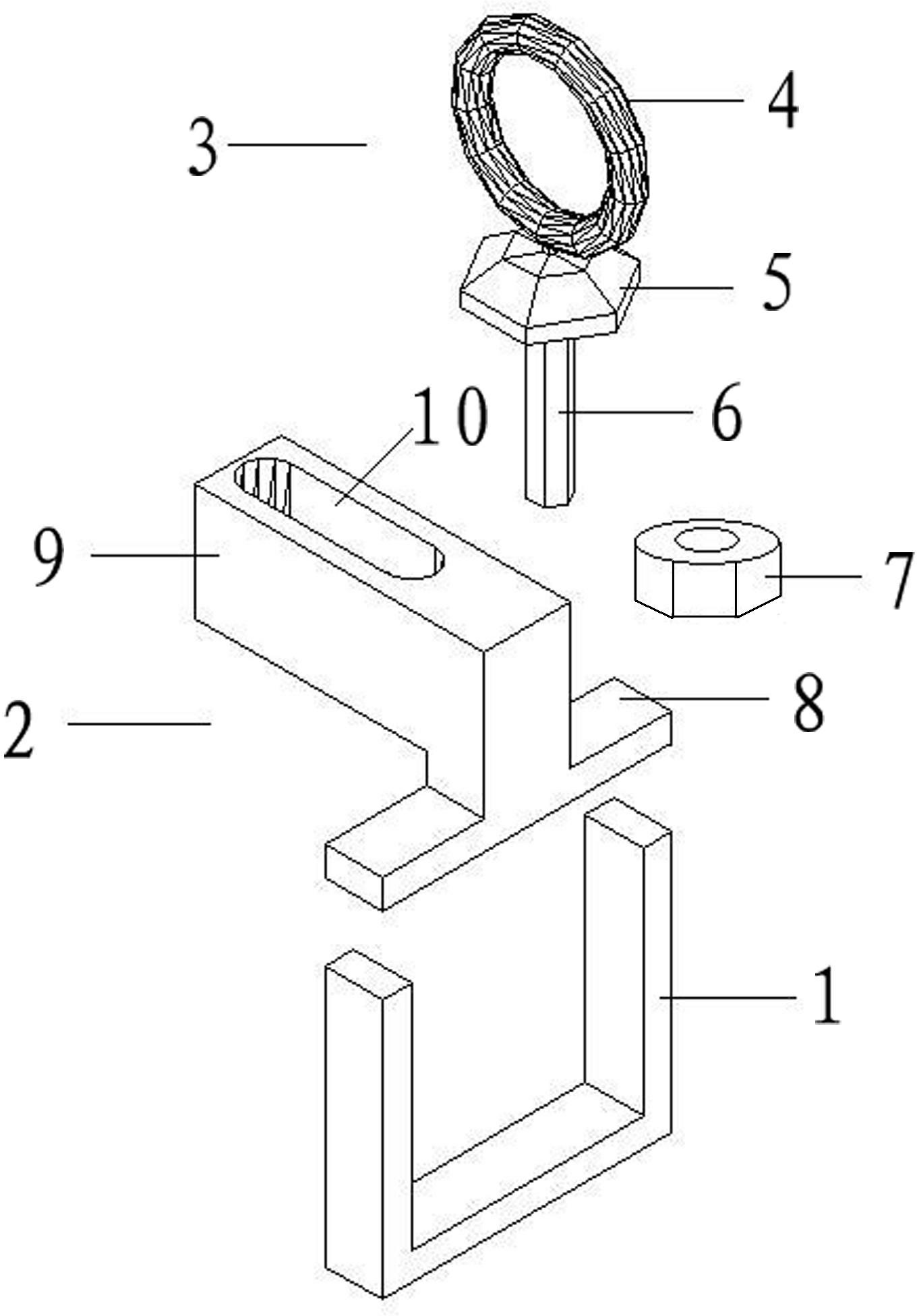

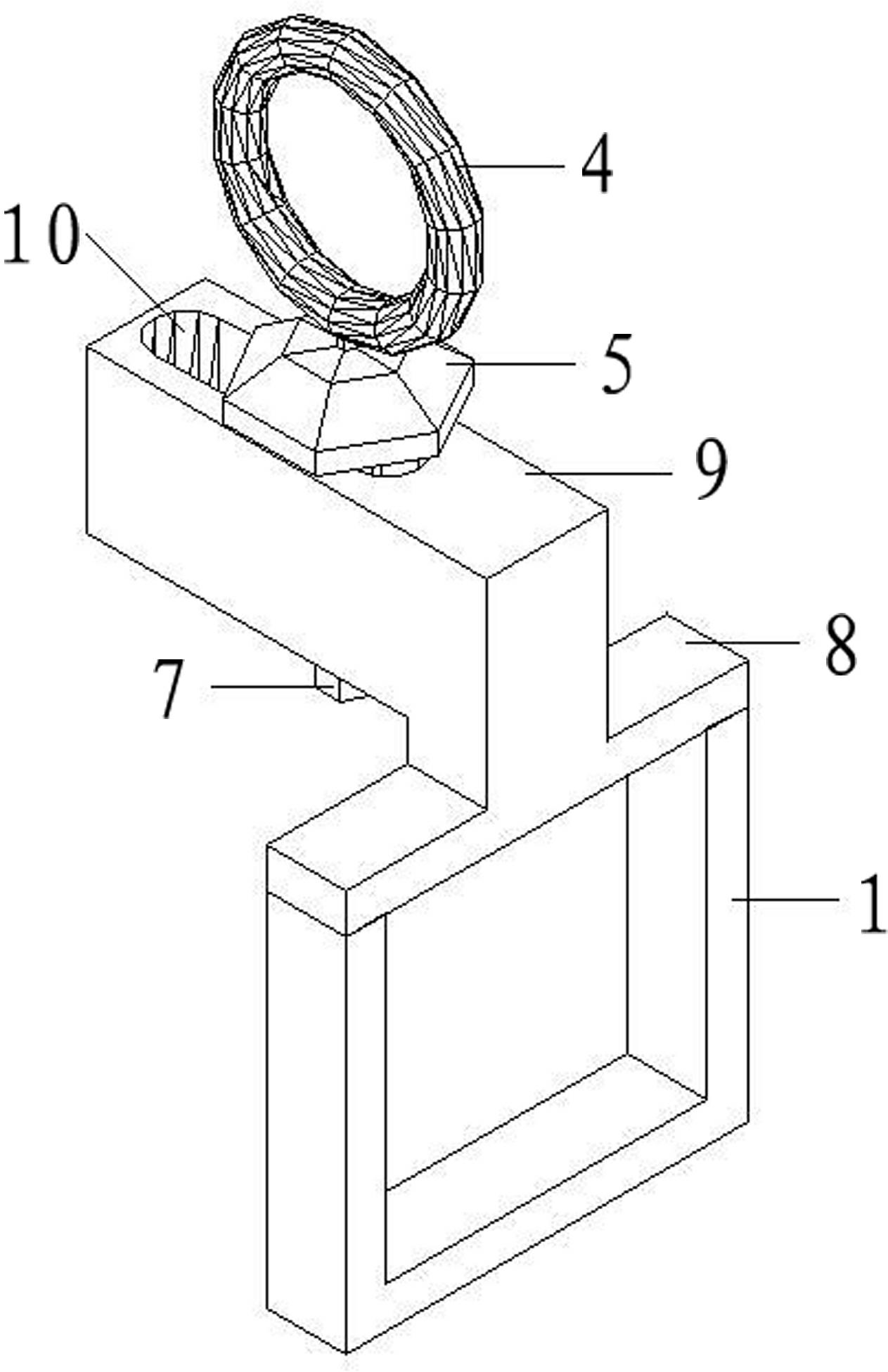

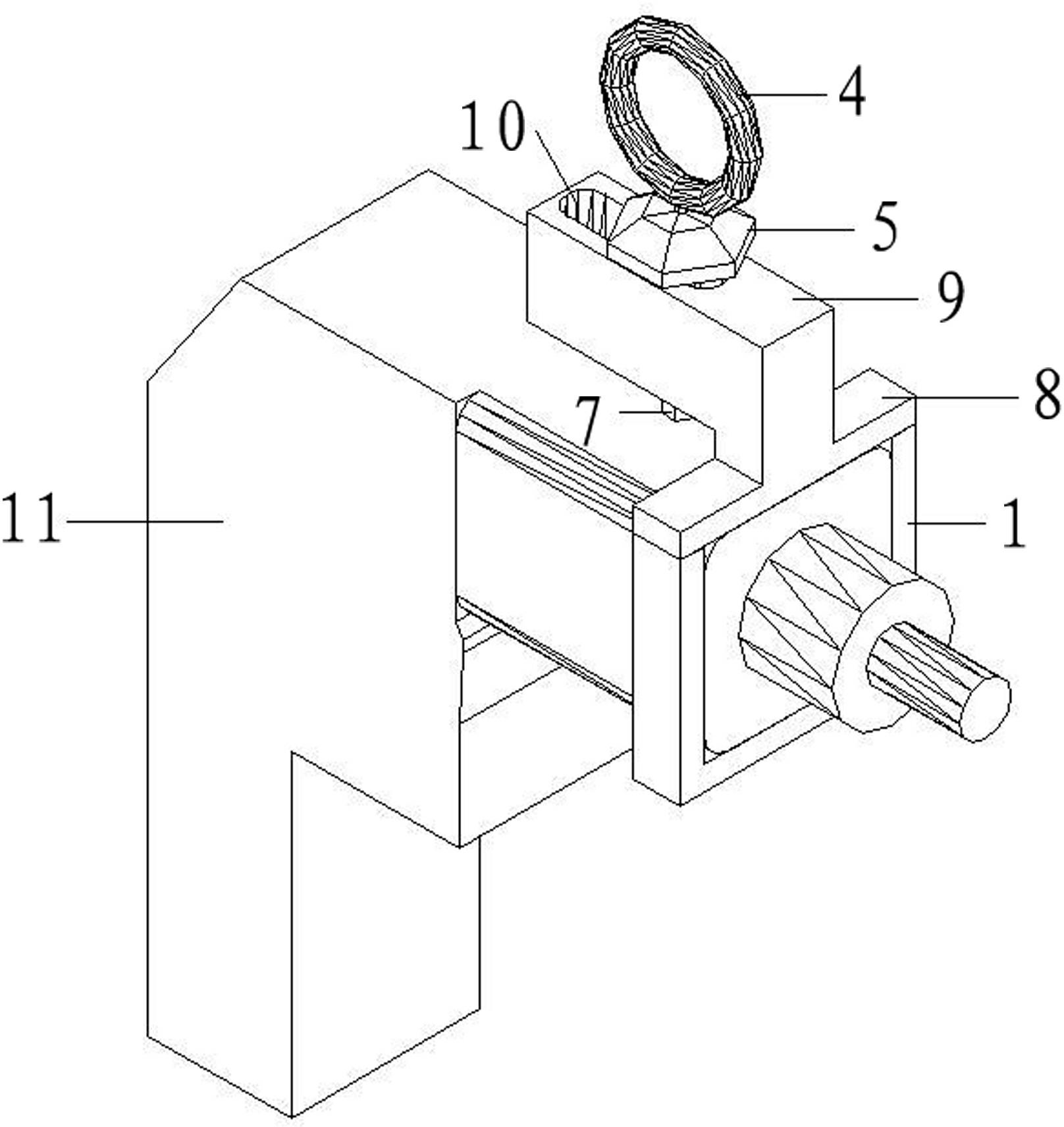

[0017] refer to Figure 1 to Figure 3 , an electric torque wrench hoisting tool, including: a U-shaped cross-section, a support frame 1 for clamping an electric torque wrench 11, and a support frame 1 for fixed connection with the support frame 1 through screws (not shown) and fastening of the electric torque wrench 11 The suspension beam 2 is used to flexibly connect with the suspension beam 2 and suspend the suspension ring 3 of the suspension beam 2.

[0018] The support frame 1 is U-shaped, and the electric torque wrench 11 is placed in it from the open end, and the three sides of the electric torque wrench 11 are just surrounded. In order to make the electric torque wrench 11 more stable, the radial dimension of the support frame 1 is just to clamp the electric Torque wrench 11 shall prevail.

[0019] The suspension beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com