Injection molding mechanism for high-performance single-cylinder injection molding machine

An injection molding machine, high-performance technology, applied in the field of injection molding mechanism, can solve the problems of long power transmission distance of pre-molding rotation, short service life of sealing parts, high price, etc., to reduce technical difficulties and manufacturing costs, improve sealing performance, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

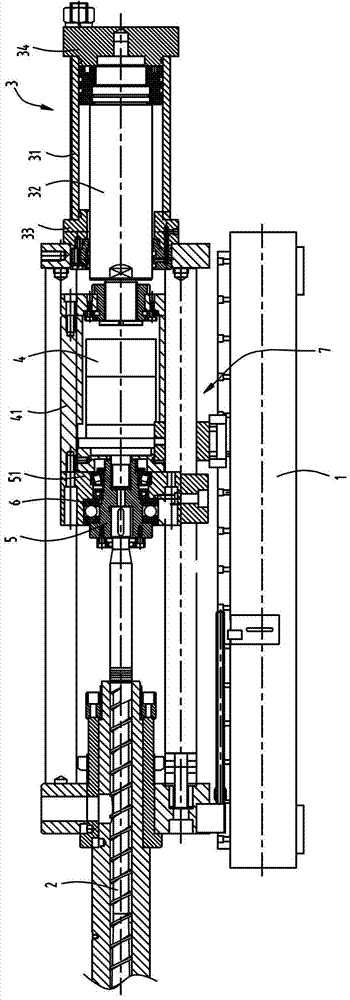

[0012] The following combination figure 1 To describe the invention in detail:

[0013] The injection molding mechanism of this single-cylinder injection molding machine includes a base 1, a screw rod 2 arranged on the base, and an injection cylinder device 3 installed on the rear side of the screw rod 2. The oil cylinder device 3 includes a cylinder body 31, a piston rod 32 and a sealing cylinder The front cover 33 and the rear cover 34 of the body, the oil in the cylinder can drive the piston rod 32 to do high-speed linear motion through differential injection; catch. In the present invention, the rear end of the screw 2 extends into one axial end of the coupling 5 and is fixedly connected to it, and the output shaft of the cycloid oil motor 4 extends into the other axial end of the coupling 5 and is fixedly connected to it. This method only uses one transmission part, and its structure is simpler compared with the prior art; and the cycloidal oil motor is moved from the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com