Frame wire harness wiring method and frame wire harness thereof

A wire harness and frame technology, applied in the field of automotive electrical appliances, can solve the problems of small wiring space for frame wire harnesses, difficulty in unifying assembly standards, inconvenient installation, etc., to avoid duplication of labor, reduce assembly errors, wiring standards and design standards Easy to unify effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

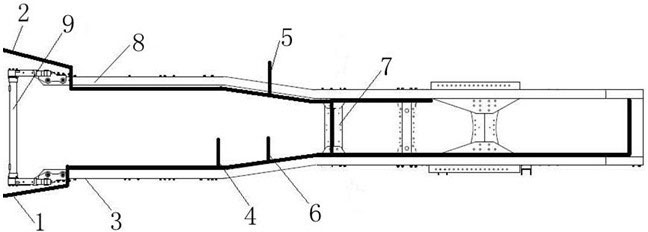

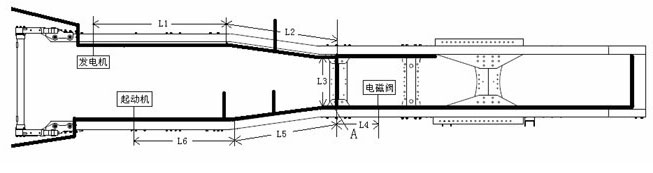

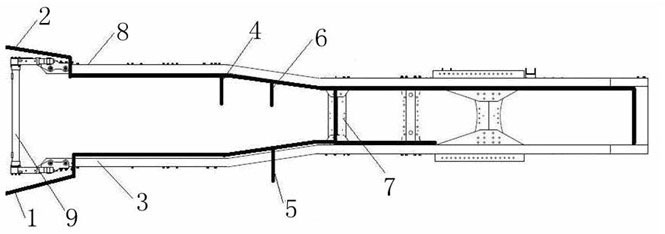

[0029] see figure 1 , figure 2 , image 3 , a wiring method for a vehicle frame wiring harness, comprising the following steps:

[0030] a. According to the wiring method in which the left longitudinal beam harness 1 and the right longitudinal beam harness 2 are connected through the second crossbeam 7 on the frame harness, calculate the length of the connecting wires between the electrical appliances on the chassis, and cut out each wire according to the length. The two ends of each wire are correspondingly installed with harness connectors;

[0031] b. Take the junction of the second beam 7 on the vehicle frame and the left side beam 3, or the junction of the second beam 7 and the right side beam 8 as the wiring reference A, according to each wire in the left side beam 3, the right side beam 8 and The lengths distributed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com