Lighting device manufacturing method

A manufacturing method and lighting device technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as difficulty in finding LED chips, inability to adjust and change series and parallel connections, and achieve flexible wiring, reduced use, and good conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

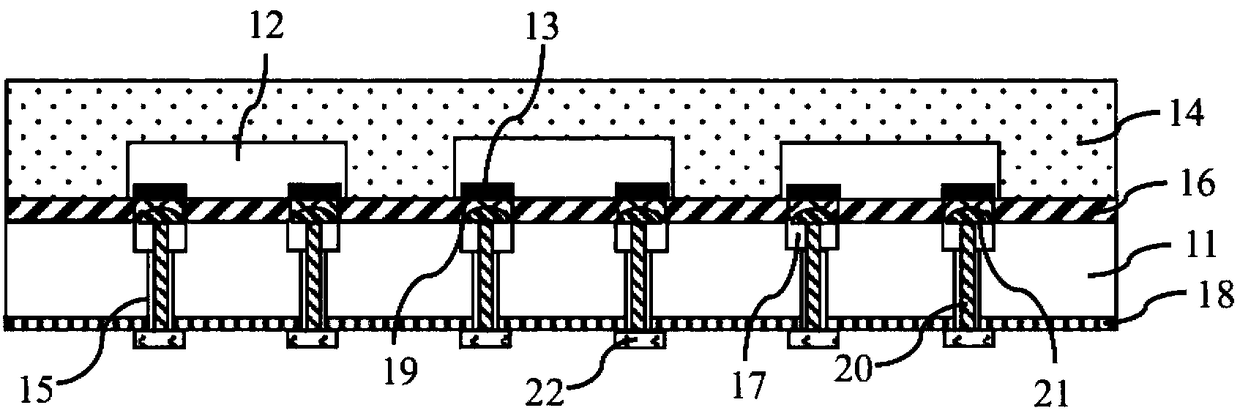

[0024] see figure 2 , the lighting device of the present invention, which comprises:

[0025] An insulating substrate 11, the insulating substrate 11 has opposite first surface and second surface, a plurality of notches 17 are arranged on the first surface, and the interior of the insulating substrate 11 also includes A plurality of through holes 15 on the bottom surface and the second surface, and its thickness is d1;

[0026] The adhesive layer 16, whose thickness is d2, is arranged on the first surface, and has a plurality of grooves 19 corresponding to the plurality of notches 17, and the plurality of grooves 19 are connected to the plurality of notches 17. The notches 17 are connected to each other;

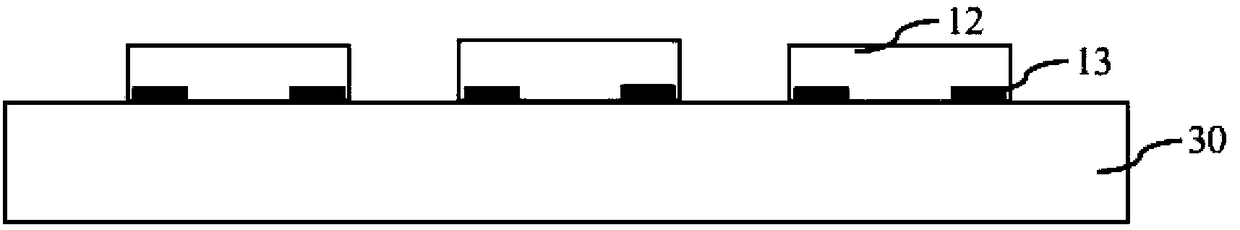

[0027] A plurality of LED chips 12, adhered to the adhesive layer 16, and have a plurality of electrode pads 13, the plurality of electrode pads 13 respectively correspond to the plurality of grooves 19 and in the plurality of grooves exposed in the groove 19;

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com