Aluminum alloy bonding wire

A technology of aluminum alloy and wedge joint, which is applied in welding equipment, welding medium, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

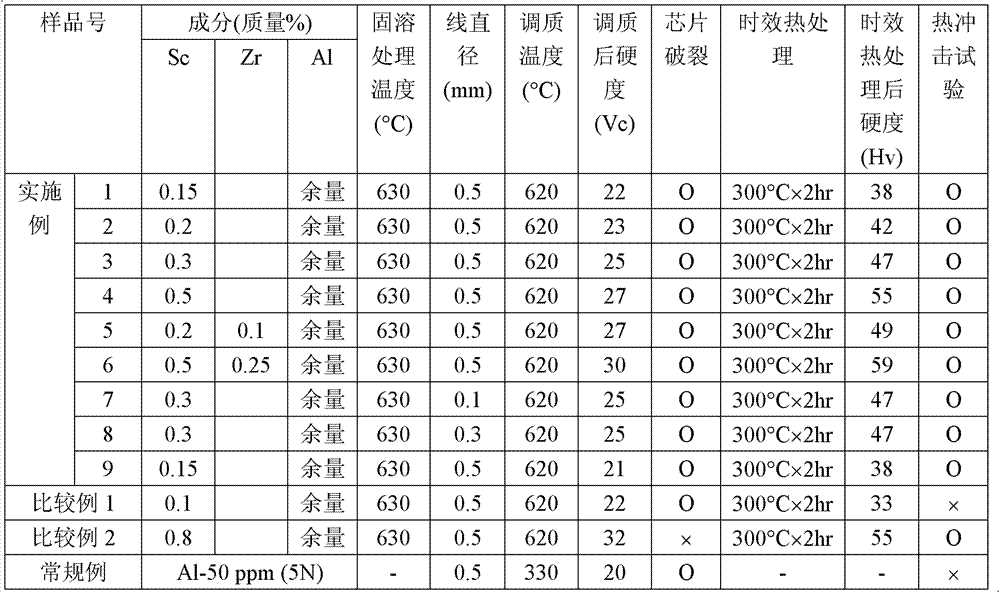

[0038] Each of the four Al-Ac alloys formed of aluminum (Al) with a purity of 99.99% by mass and scandium (Sc) with a purity of 99.9% by mass, namely, Al-0.15%Sc, Al-0.2%Sc , Al-0.3%Sc and Al-0.5%Sc were melted and then continuously casted to obtain an aluminum alloy ingot with a diameter of 300mm.

[0039] Element aluminum alloy wires having a diameter of 5 mm were produced by rolling each ingot using a grooved roll and then drawing. The primary wire was then solution heat treated at 630 °C x 120 min, followed by quenching in water. Thereafter, continuous wire drawing was performed in water using a diamond die to obtain a diameter of 0.5 mm, followed by tempering heat treatment at 620° C.×1 min, followed by water cooling.

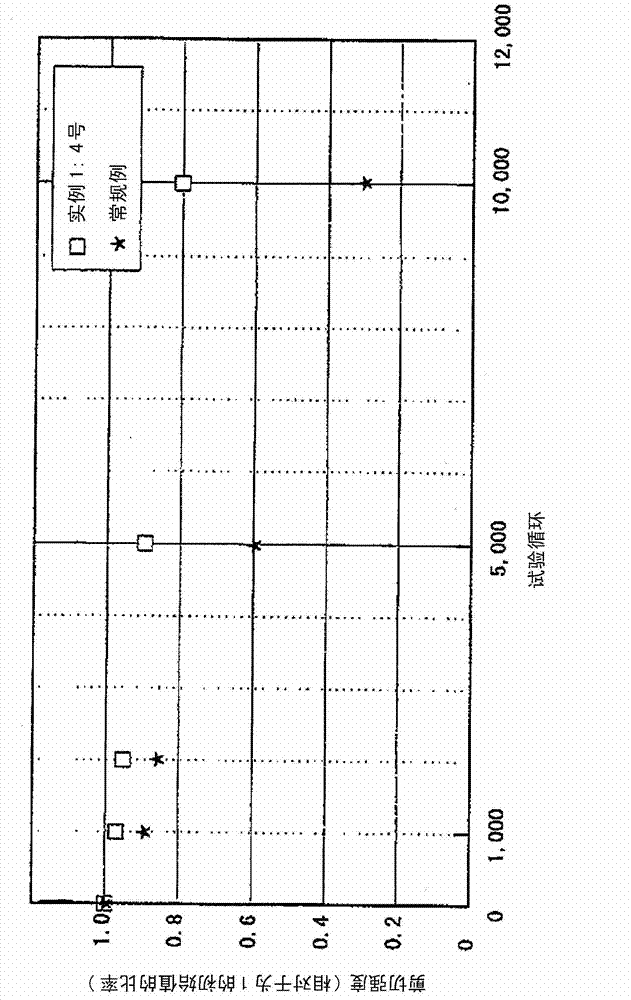

[0040] The samples were used as Example 1 (Samples 1 to 4). Each of Example 1 was measured using a micro Vickers hardness tester (Model MVK-G3 produced by Akashi Corporation). The measured hardness values are shown in Table 1.

[0041] Each of Exampl...

Embodiment 2

[0057] By using Al-0.2%Sc-0.1%Zr and Al-0.5%Sc-0.25%Zr alloys, in the same manner as in Example 1, fine aluminum alloy wires each having a diameter of 0.5 mm were prepared for use as examples 2 (Samples 5 and 6), each of which was formed of aluminum (Al) with a purity of 99.99% by mass, scandium (Sc) with a purity of 99.9% by mass, and zirconium (Zr) with a purity of 99.9% by mass.

[0058] Subsequently, under the same conditions as those of Example 1, the samples were subjected to ultrasonic bonding and aging heat treatment.

[0059] Under the same conditions as in Example 1, the above test was performed. The test results are shown in Table 1.

Embodiment 3

[0061] By using the Al-0.3% Sc alloy, in the same manner as in Example 1, thin aluminum alloy wires with a diameter of 0.1 mm and a diameter of 0.3 mm were respectively prepared for Example 3 (samples 7 and 8), so The alloy is formed of aluminum (Al) with a purity of 99.99% by mass and scandium (Sc) with a purity of 99.9% by mass.

[0062] Subsequently, under the same conditions as those of Example 1, the samples were subjected to ultrasonic bonding and aging heat treatment.

[0063] Under the same conditions as in Example 1, the above test was performed on the sample. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com