Double-wedge block braking system for transportation monorail of inclined shaft mine car rail

A technology of rail transportation and braking system, applied in the field of mine safety, can solve the problems of no solution, broken rope of traction wire rope, car crash and death, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

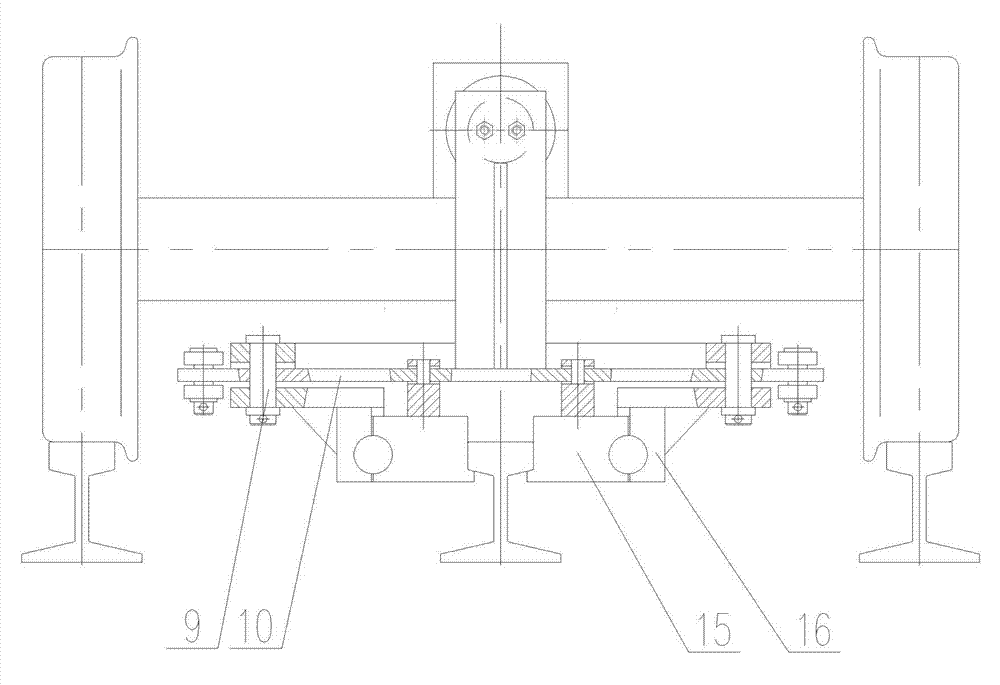

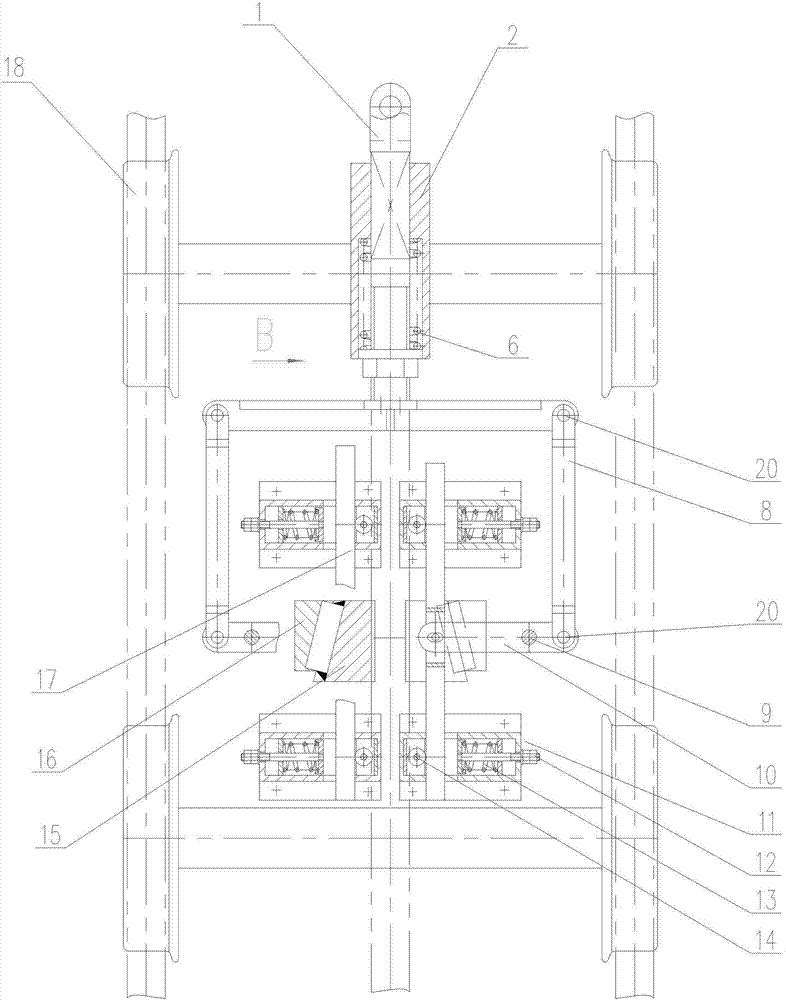

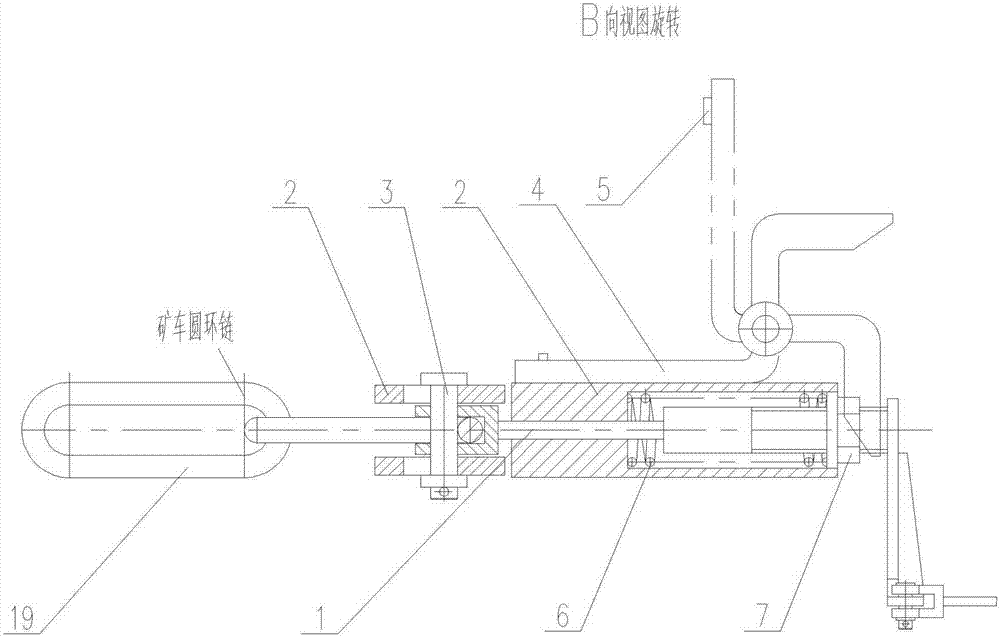

[0014] As shown in the accompanying drawings: a single-track double-wedge brake system for inclined mine car rail transportation, the brake system includes a frame 2, a pull rod 1 is arranged on the frame, and a brake spring 6 is arranged at the rear of the pull rod 1. There is also a brake key 4 on the frame described above, and a key baffle plate 5 is arranged on the brake key 4; the rear end of the pull rod 1 is connected with a plate-shaped part through bolts, and the two ends of the plate-shaped part are hinged through the pin shaft II20. Two rods 8 are symmetrically arranged on both sides of the track. The rear ends of the two rods 8 are respectively hinged to the connecting rod 10 through the pin shaft II20, and the middle part of the connecting rod 10 is hinged on the frame through the pin shaft I9. The inner ends of the connecting rods 10 are respectively hinged with guide rods 17, and the two guide rods 17 are welded and fixed with movable wedges 15; the frame 2 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com