A kind of anti-graffiti coating suitable for outdoor facilities and preparation method thereof

An anti-graffiti and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficulties, high adhesion, and damaged surfaces, and achieve reduced negative effects, good early water resistance, and excellent adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

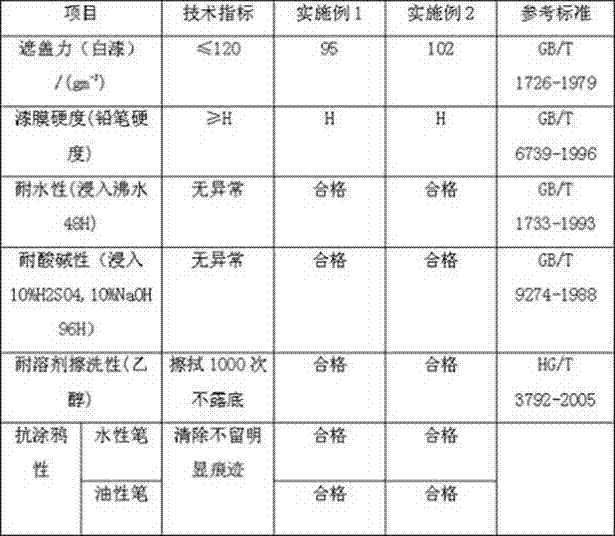

Examples

Embodiment 1

[0016] Embodiment 1: A kind of anti-graffiti coating suitable for outdoor facilities of this example, its component and mass parts are: soybean oil polyurethane dispersion (solid content 30%) 42 parts, methacrylic acid-2,2,2 - 23.8 parts of trifluoroethyl ester, 28 parts of pigment and filler, 6 parts of auxiliary agent, and 0.2 part of initiator.

[0017] Its preparation method is:

[0018] a. Add soybean oil, hydrogen peroxide and formic acid into the reactor by weight ratio, keep the temperature of the system at 40°C for 24 hours, and obtain liquid A after removing moisture; add liquid A, measured isopropanol, methanol and fluoroboric acid into In the reactor, keep the temperature of the system at 50°C for 2 hours to remove moisture to obtain liquid B; add liquid B, isophorone diisocyanate, and 2,2-dimethylolpropionic acid into the reactor, under nitrogen protection Under the condition of mechanical stirring, react at 78°C for 2 hours, then add triethylamine and distilled...

Embodiment 2

[0020] Embodiment 2: A kind of anti-graffiti coating suitable for outdoor facilities of this example, its component and mass parts are: 45 parts of soybean oil polyurethane dispersion liquid (solid content 30%), 12 parts of hexafluorobutyl methacrylate , 13.8 parts of dodecafluorobutyl methacrylate, 22 parts of pigments and fillers, 7 parts of additives, and 0.2 parts of initiator.

[0021] Its preparation method is:

[0022] a. Add soybean oil, hydrogen peroxide and formic acid into the reactor according to the weight ratio, keep the system temperature at 50°C and react for 23 hours, and obtain liquid A after removing moisture; add liquid A, measured isopropanol, methanol and fluoroboric acid into In the reactor, keep the system temperature at 55°C for 2 hours to remove moisture to obtain liquid B; add liquid B, isophorone diisocyanate, and 2,2-dimethylolpropionic acid into the reactor, under nitrogen protection Under the condition of mechanical stirring, react at 78°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com