Closed penetration-free filament collecting device used for reeling silk

A thread collector and closed technology, applied in the direction of silk reeling, etc., can solve problems such as the decline of silk thread quality, and achieve the effect of improving quality and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

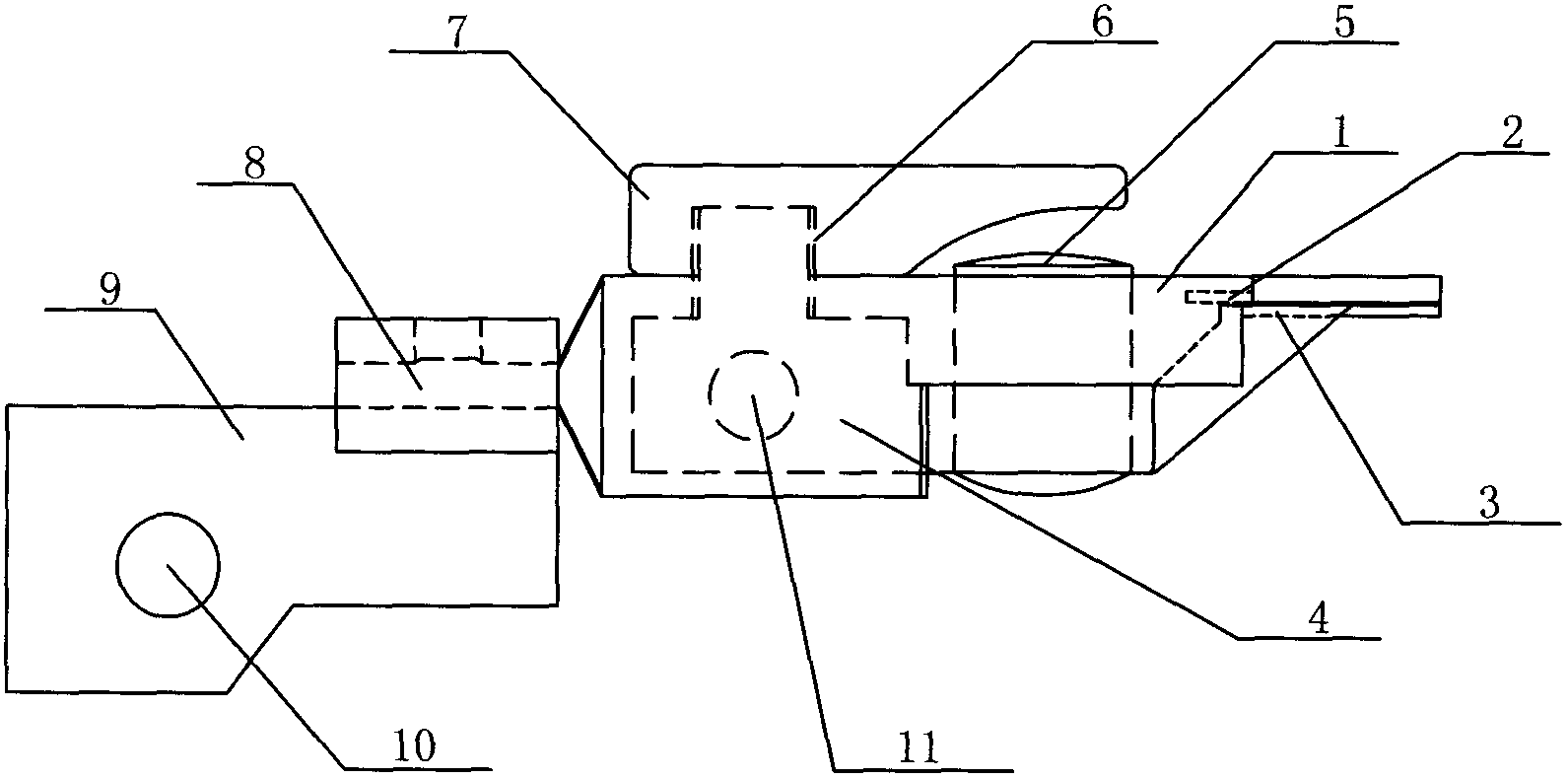

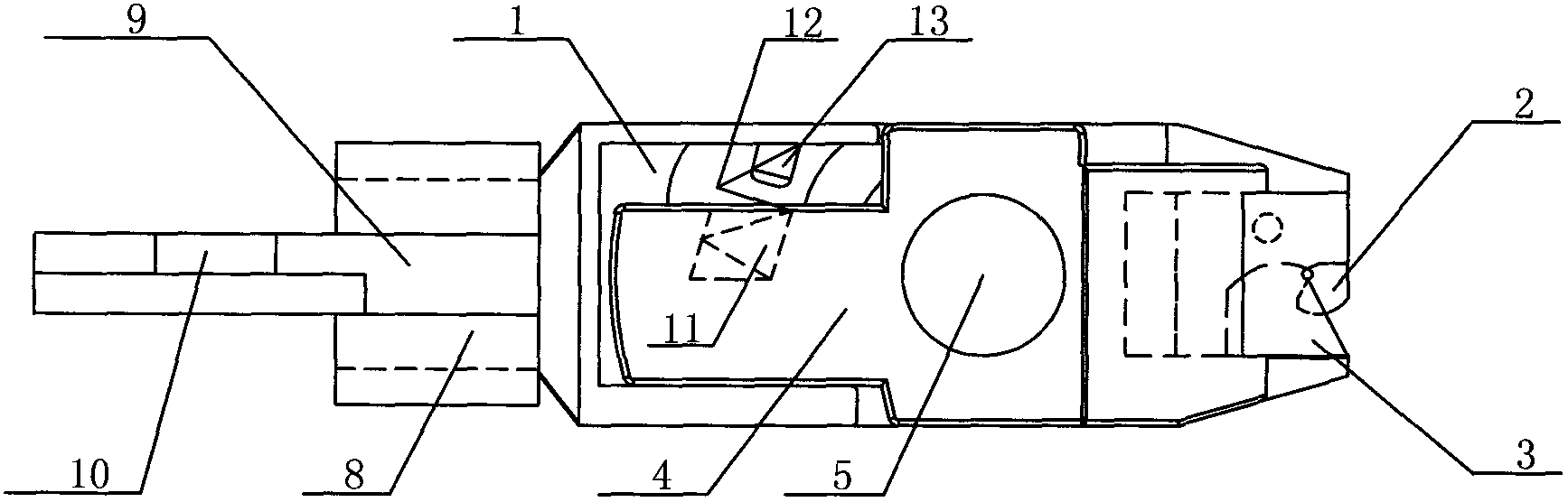

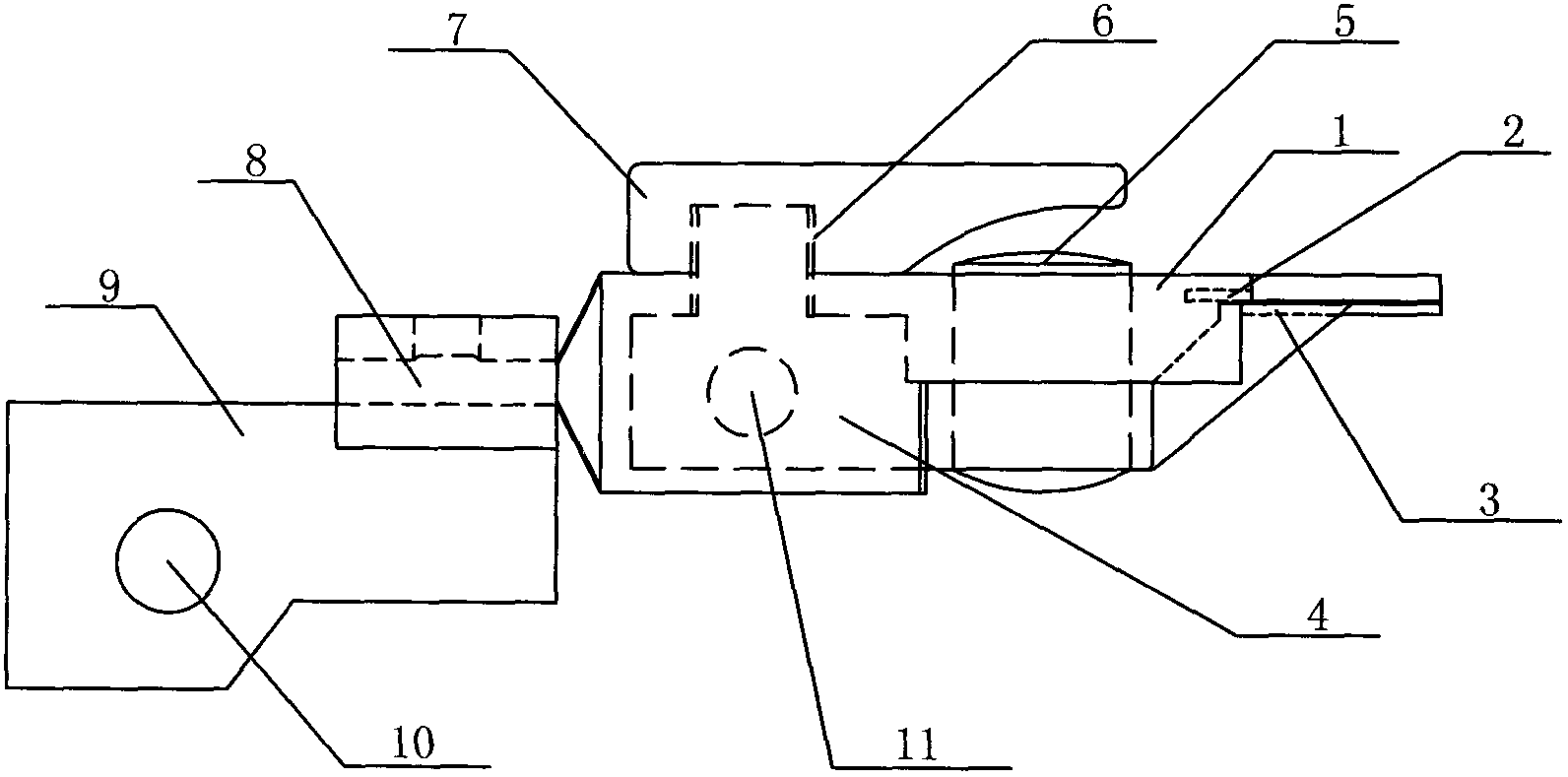

[0013] Such as figure 1 , 2 A closed thread-free thread collection device for silk reeling is shown, which includes a round hole-shaped thread collection hole, a first porcelain plate holder 1 with a first ceramic plate 2 installed at the end, and a second ceramic plate 3 installed at the end The second tile fixing frame 4, the second tile fixing frame 4 and the first tile fixing frame 1 are positioned and connected by the pin 5, and the described thread-collecting hole is formed by superimposing two sections of circular arcs, and a section of the circular arc is located at the first On one tile 2, the other section of arc is located on the second tile 3. When the first tile 2 and the second tile 3 are closed, a collection hole is formed. Between the first tile 2 and the second tile 3, a There is a gap, and there is an axial gap in the two circular arcs that constitute the thread-collecting hole; when the first ceramic sheet 2 and the second ceramic sheet 3 are closed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com