Scaffold with expanded working platform

A technology of working table and scaffolding, which is applied in the field of scaffolding and can solve the problems of small working surface and large floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

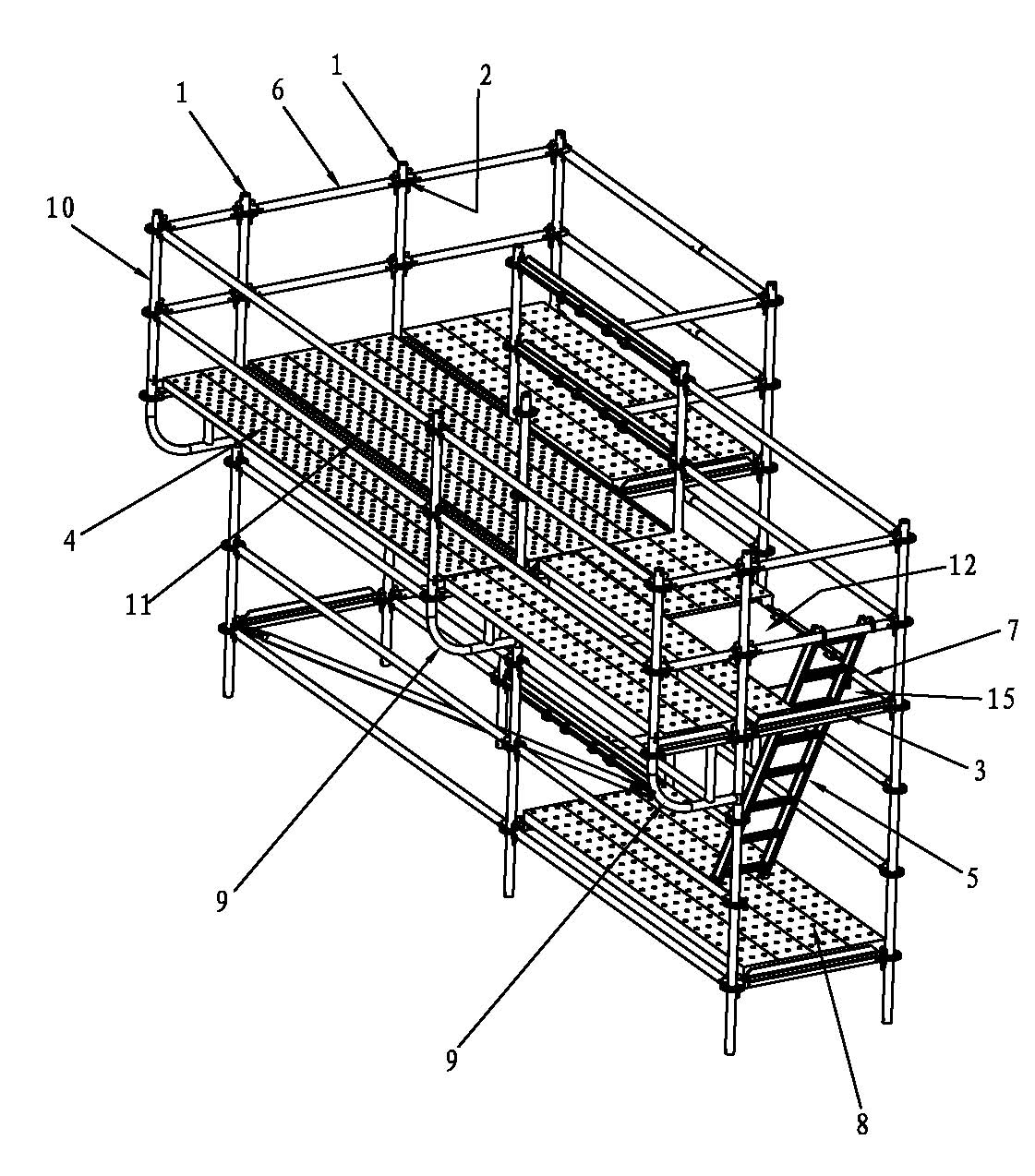

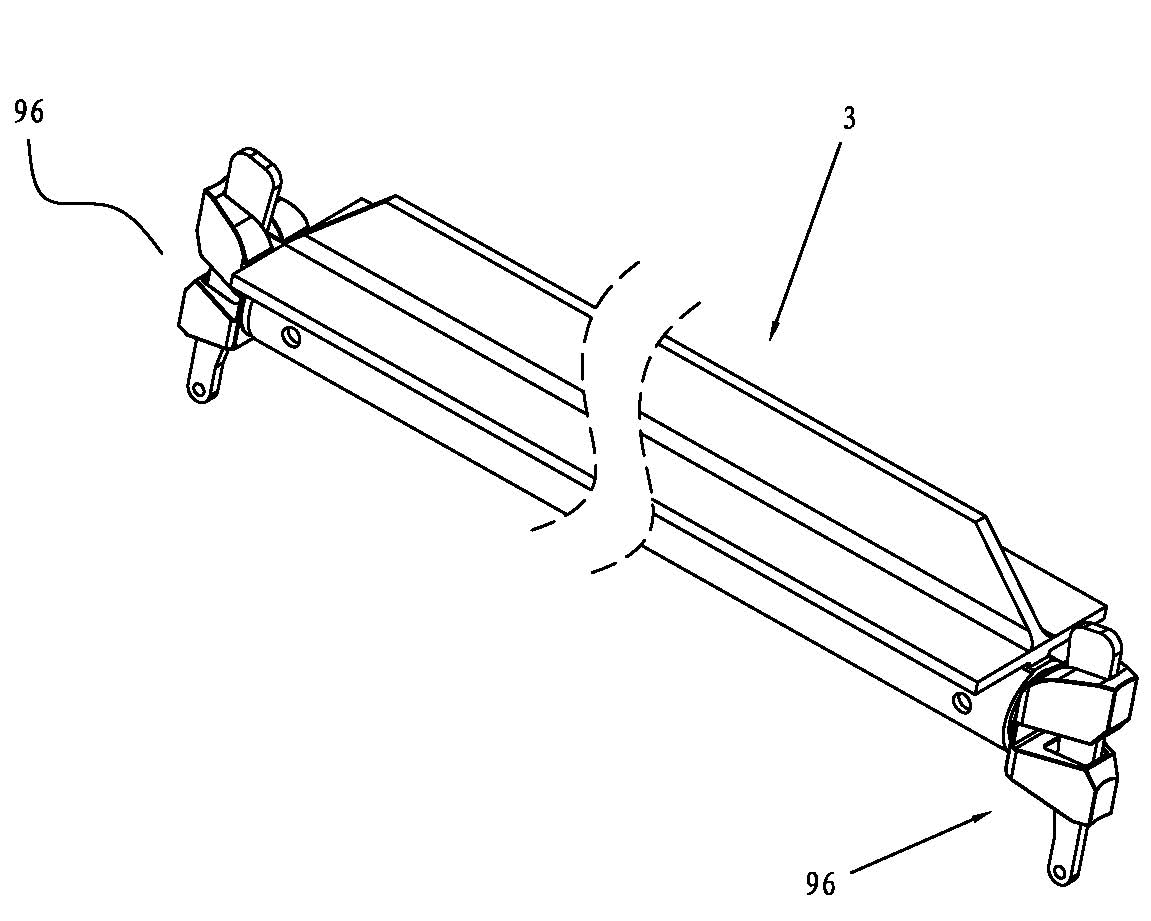

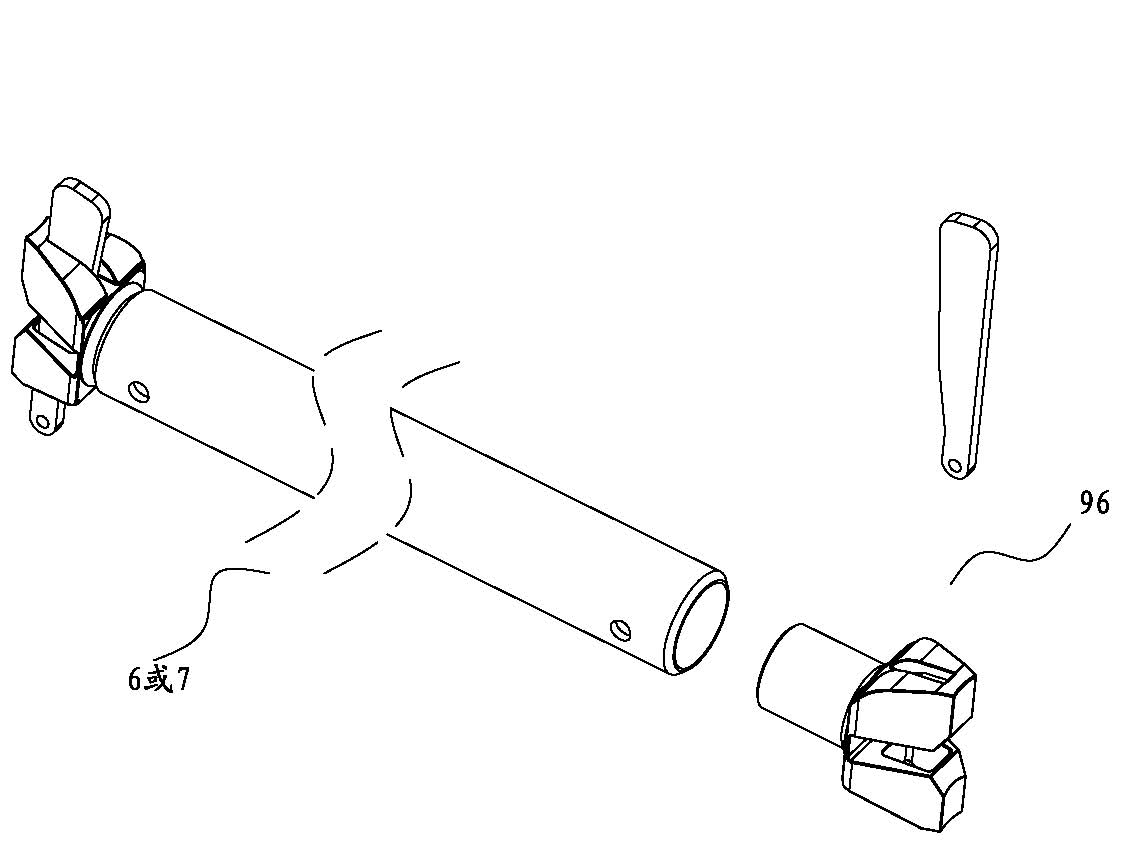

[0028] Such as figure 1 , figure 2 As shown, a scaffold for expanding the work surface, including a standpipe 1, a support plate 2 arranged on the standpipe 1, a support device 3, a foot pedal 4, a hanging ladder 5 and a guardrail horizontal pipe 6, two in the width direction The support plate 2 of a riser 1 is detachably connected with the support device 3, the pedal 4 is arranged on the support device 3, and the support plates of the two riser 1 in the length direction are detachably connected with the long horizontal tube 7; the bottom has The upper and lower table tops 8 have an inlet and outlet 15 on the upper part, and the upper part of the hanging ladder 5 passes through the inlet and outlet 15 and hasps with the guardrail horizontal pipe 6, and the lower end of the hanging ladder 5 is supported by the upper and lower table tops 8; Detachable connection.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com