Vertical cementing manifold for offshore oil production

A vertical and offshore technology, applied in the direction of drilling pipes, casings, and mining fluids, etc., it can solve the problems of inconvenient operators, large number of manifold elbows, and large floor space, so as to achieve convenient operation and reduce occupation Ground area, the effect of reducing welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

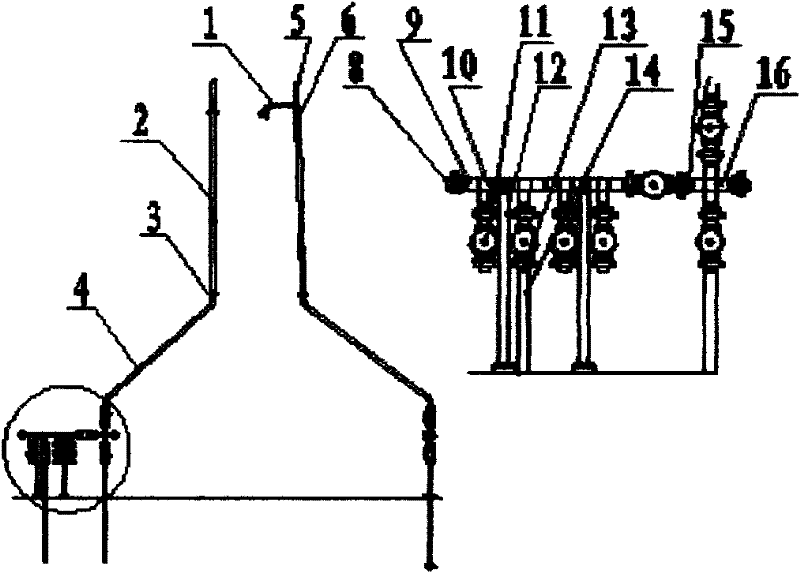

[0017] Such as figure 1 As shown, the vertical cementing manifold for offshore oil production includes straight pipe A1, straight pipe B2, 120° elbow 3, straight pipe C4, top support pipe 5, tee A6, union male A7, Nut 8, female union head 9, tee B10, plug valve 11, support assembly 12, male union head B13, straight pipe D14, extended union female head 15 and cross 16, in the cementing pipe body The lower part of the installation manifold.

[0018] In the vertical cementing manifold for offshore oil production of the present invention, a straight pipe A1 and a straight pipe B2 are installed on the upper part of the pipe body.

[0019] In the vertical cementing manifold for offshore oil production of the present invention, a 120° bend pipe 3 and a straight pipe C4 are installed in the middle of the pipe body.

[0020] In the vertical cementing manifold for offshore oil production of the present invention, a top support pipe 5 and a tee A6 are installed on the top of the pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com