A pump body cooling circulation system of a rotary compressor

A rotor compressor and circulation system technology, applied in the field of compressors, can solve problems such as heat removal, and achieve the effects of improving efficiency, reducing exhaust temperature and suction superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

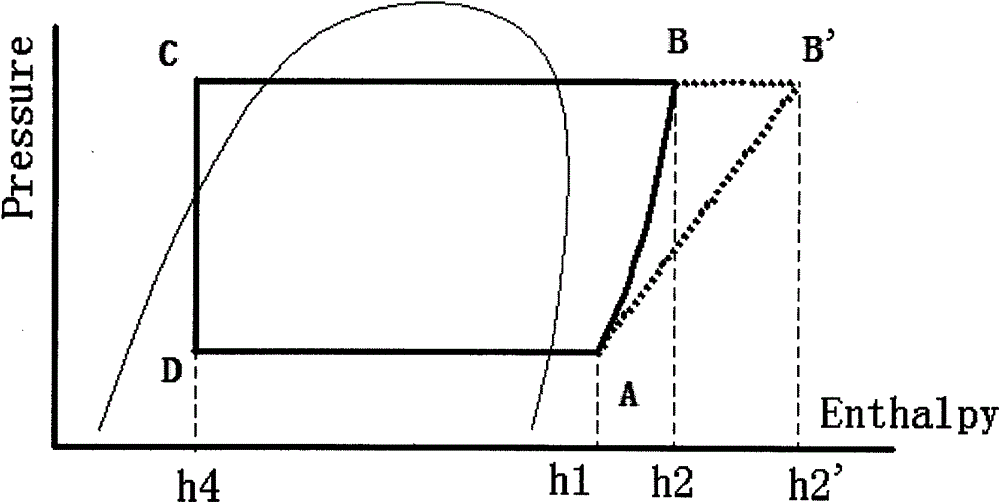

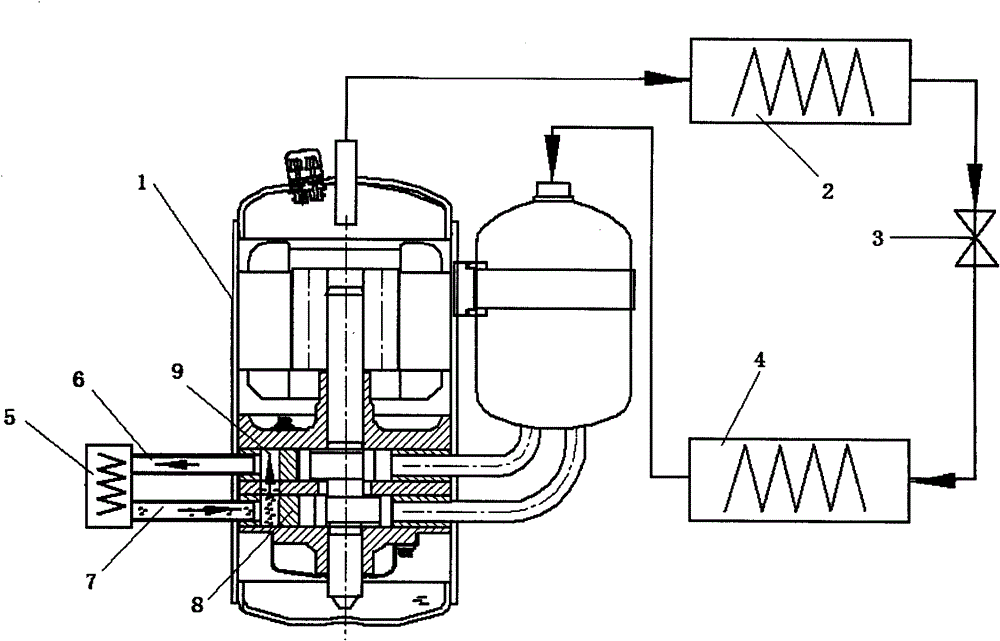

[0021] Such as Figure 2-5 As shown, an air conditioning cycle system includes a compressor 1, a first condenser 2, an expansion valve 3 and an evaporator 4, and the exhaust port of the compressor 1 is connected to the first condenser 2, the expansion valve 3 and the evaporator in sequence. The evaporator 4 is connected to the suction port of the compressor 1.

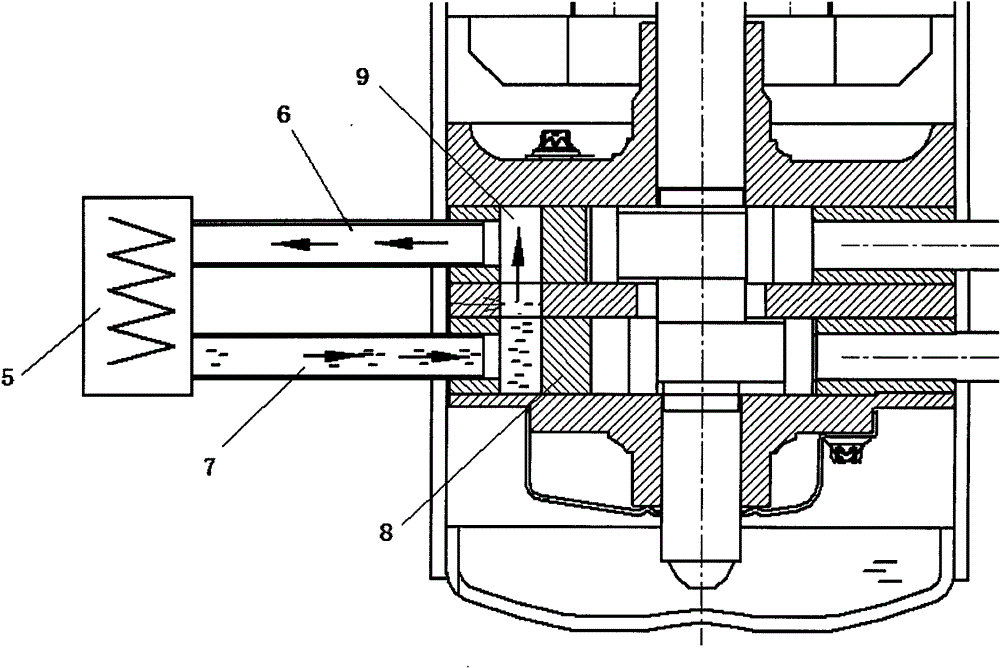

[0022] The above-mentioned compressor 1 is additionally provided with a pump body cooling circulation system, which is arranged on the pump body of the compressor, including a second condenser 5, an exhaust pipe 6 and a liquid inlet pipe 7, and the pump body includes an upper cylinder head, a cylinder and The lower cylinder head is provided with a closed cavity 9 on the cylinder 8, and the structure of the closed cavity 9 opened on the cylinder is as follows: Figure 4-5 shown. Two pipes are respectively connected up and down in the airtight cavity 9, and the compressor casing is led out to connect with the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com