Bidirectional clutch

A two-way clutch and star wheel technology, applied in the field of clutches, can solve the problems of difficult processing, poor reliability, inability to drive the star wheel 10 and circuit breakers, etc., and achieve the effect of reducing production costs and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

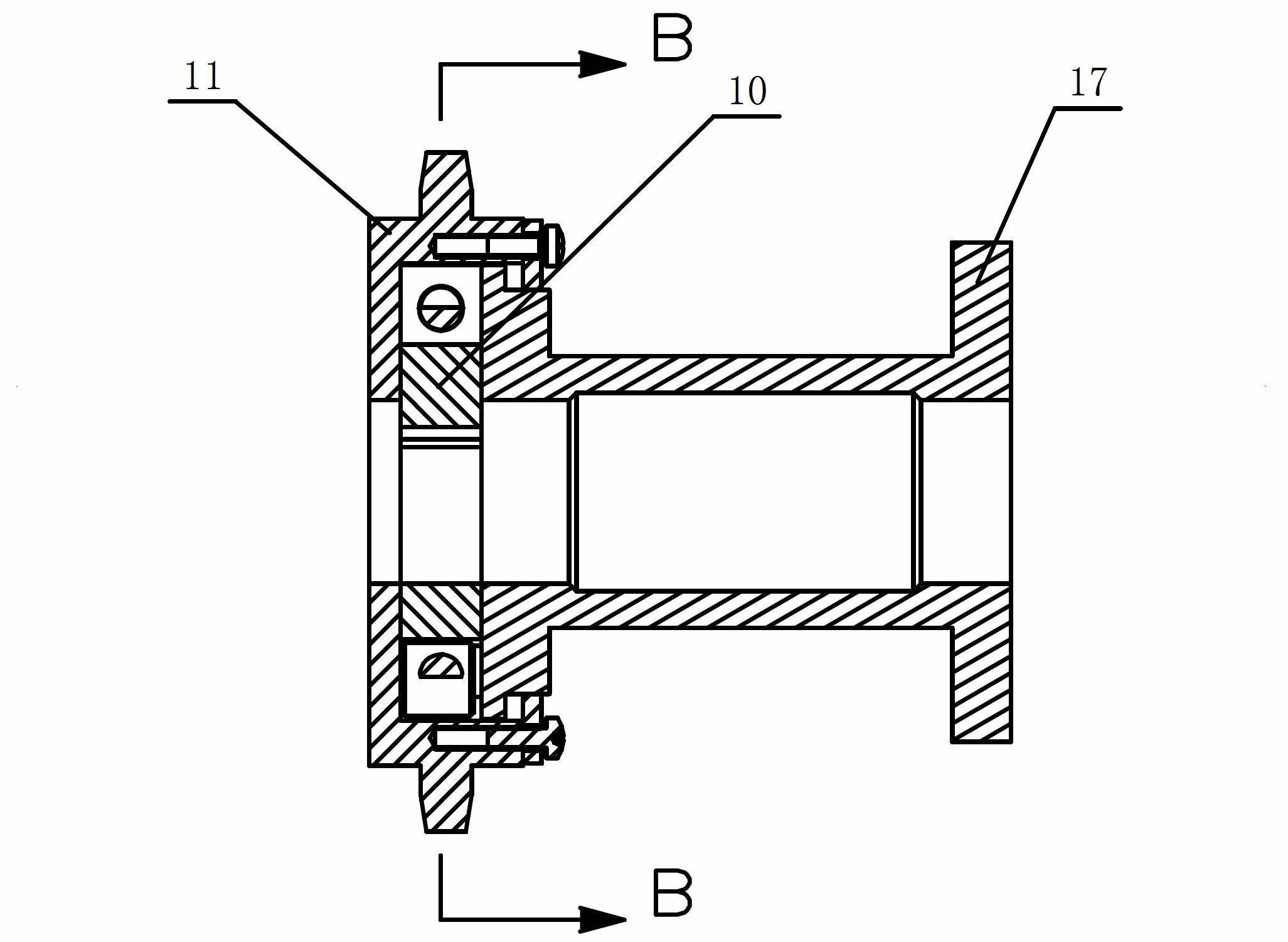

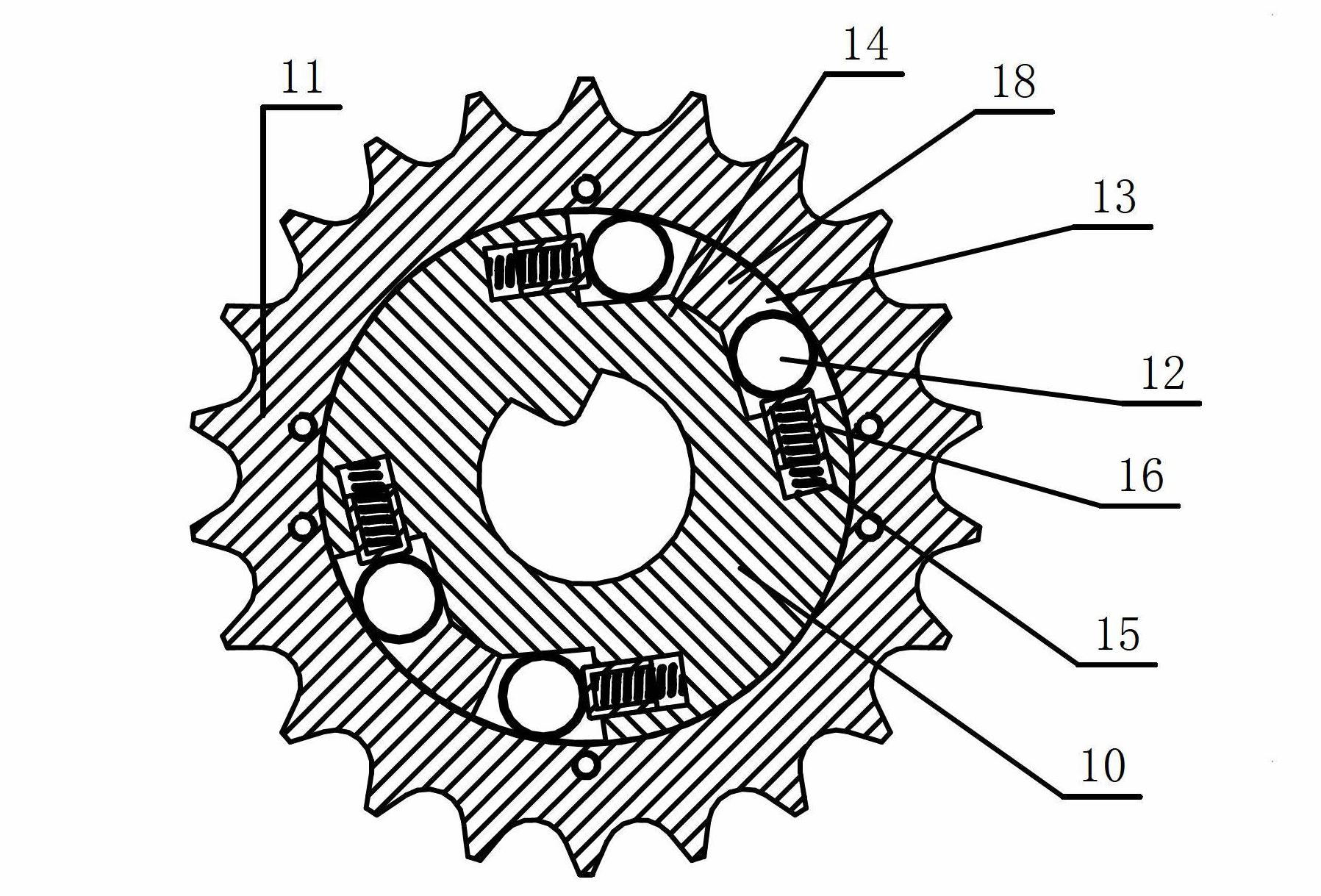

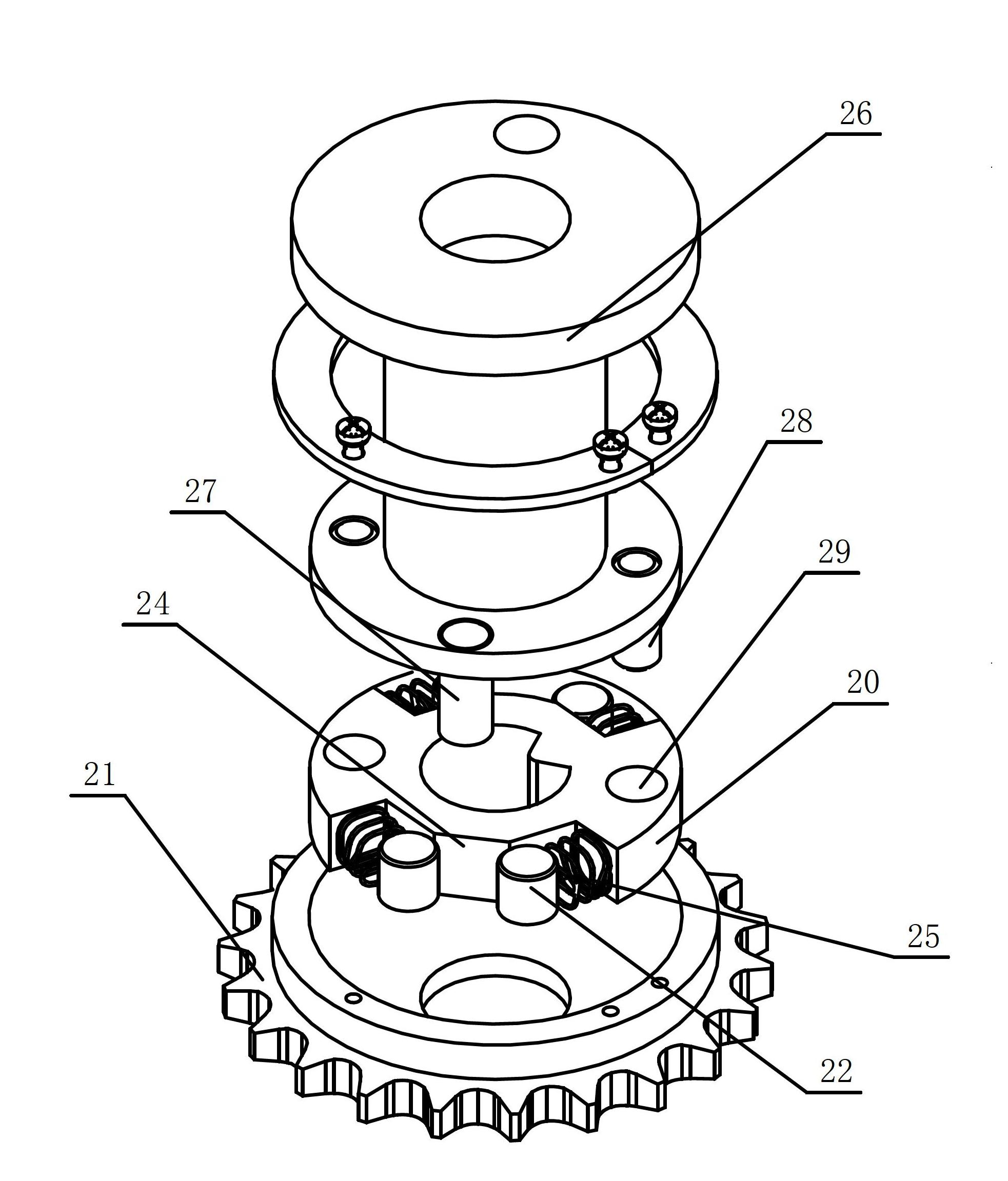

[0021] see Figure 3 to Figure 5 As shown, in this embodiment, a two-way clutch includes a star wheel 20 and a sprocket 21 that is coaxially assembled outside the star wheel 20 in a relatively rotatable manner. Two grooves 23 for accommodating the rollers 22 are processed in the grooves 23 with a wedge 24, and rollers 22 are arranged on both sides of the wedge 24, and the side walls of the grooves 23 are adjacent to the grooves. A coil spring 25 is arranged between the rollers 22 of the side wall, and the driving rod 27 of the shift fork 26 is arranged between the two rollers 22 in the groove 23, and two shift needles 28 are installed on the shift fork 26, Two clamping holes 29 are processed on the wheel surface of the star wheel 20 corresponding to the setting pins 28 , and the setting pins 28 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com