Electric vehicle and three-clutch transmission device for same

A technology for electric vehicles and clutches, which is used in transmissions, vehicle gearboxes, multi-gear ratio transmissions, etc., to achieve the effects of good shifting quality, low cost, and short shifting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

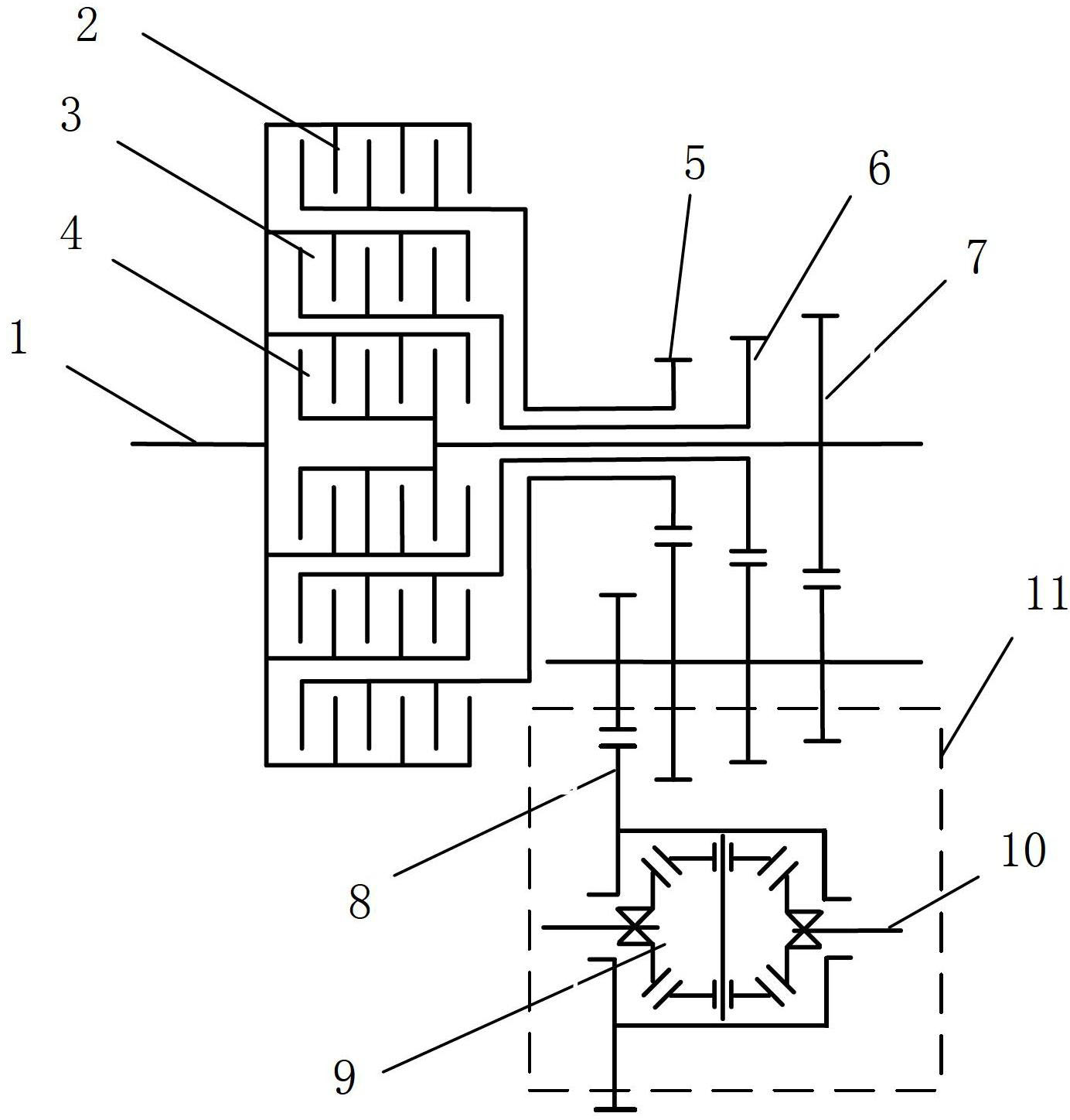

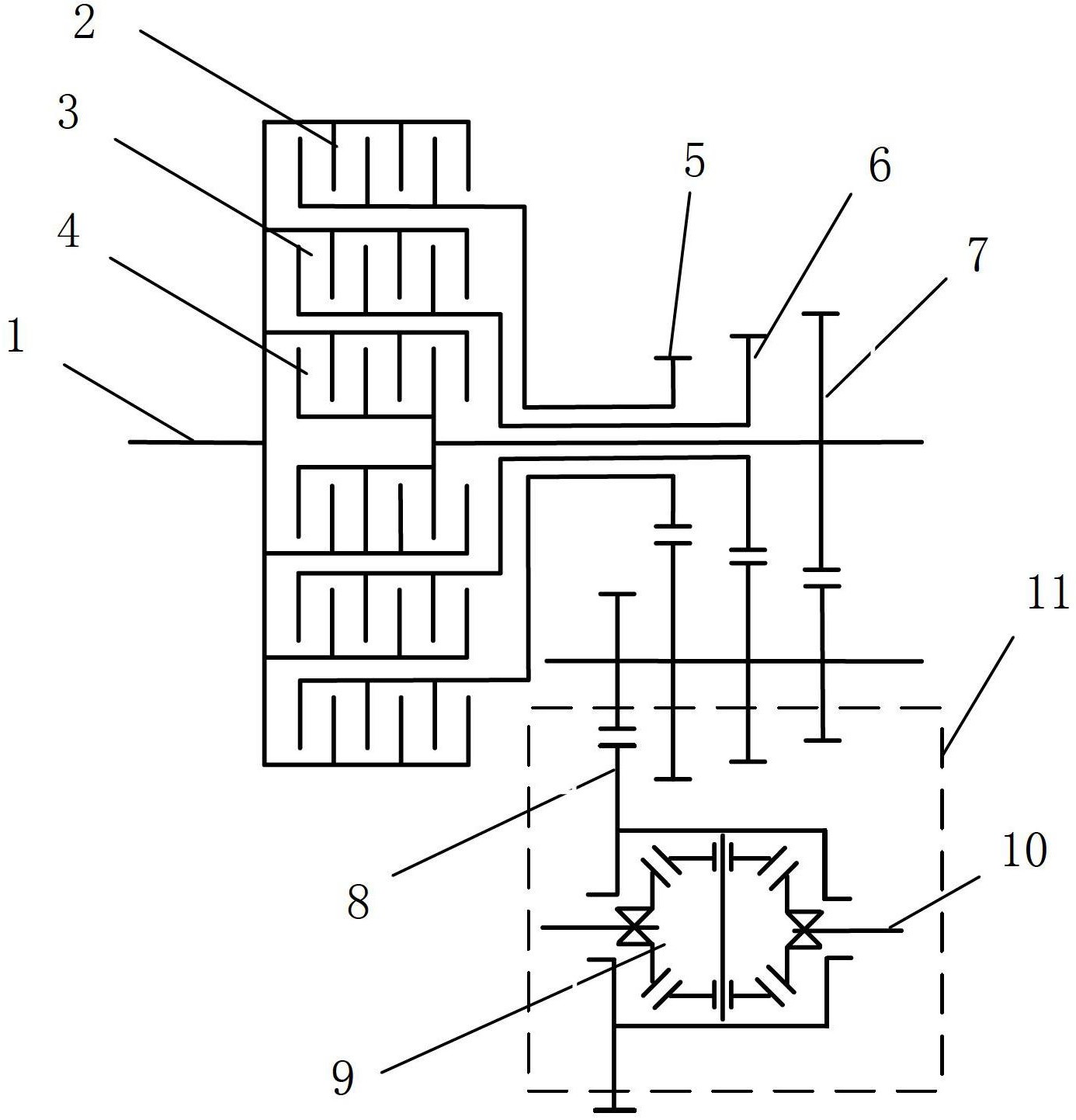

[0012] Refer to the following figure 1 Examples of the present invention will be described.

[0013] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Such as figure 1 As shown, a three-clutch transmission device for electric vehicles includes an input shaft 1, K1 clutch 2, K2 clutch 3, K3 clutch 4, first gear 5, second gear 6, third gear 7, output shaft 10 , the transmission device 11 and the gear controller (not shown in the figure), the K1 clutch 2, the K2 clutch 3, and the K3 clutch 4 are respectively connected with the 1st gear 5, the 2nd gear 6, and the 3rd gear 7, and the gears The controller automatically controls the input shaft 1 to access different gears through different clutches, and the output shaft 10 is connected to the shift gear through the transmission device 11 . The transmission d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com