Gearbox transmission system

A technology of gearbox transmission and transmission structure, applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., can solve the problems of bad road conditions, power interruption, hidden danger of accidents, etc., and achieve high gear safety factor and shift time. Short, small shift failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

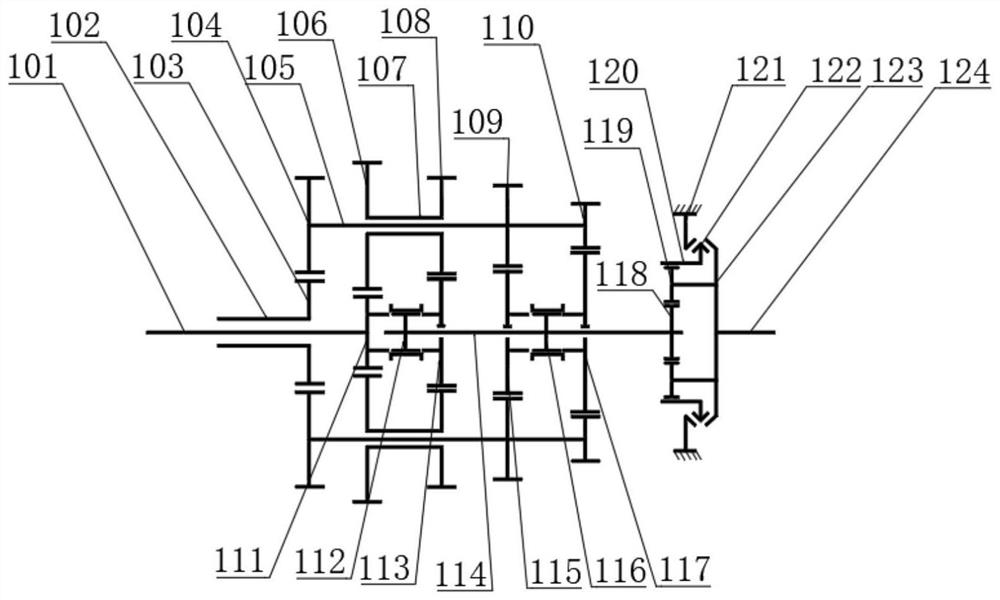

[0038] According to a preferred embodiment of the present invention, see figure 1 , provides a transmission transmission system, characterized in that comprising:

[0039] The first input shaft 101 is connected with the first motor;

[0040] The second input shaft 102 is connected with the second motor and sheathed on the outside of the first input shaft 101 in a relatively rotatable manner;

[0041] The first converging gear 103 is connected to the second input shaft 102;

[0042] The first transmission structure unit and the second transmission structure unit both include: a first splitter gear 104; a first parallel shaft 105; a second parallel shaft 107, which is relatively rotatably sleeved outside the first parallel shaft 105; The second splitter gear 106 and the third splitter gear 108 are respectively connected to both ends of the second parallel shaft 107; the fourth splitter gear 109 and the fifth splitter gear 110 are respectively connected to the first parallel sh...

Embodiment approach

[0055] According to another preferred embodiment of the present invention, the first to fifth splitter gears and the sun gear 118 are sequentially arranged along the direction of the first parallel axis 105 .

[0056] According to yet another preferred embodiment of the present invention, the first to fifth converging gears are arranged in sequence along the direction of the first input shaft 101 .

[0057] According to yet another preferred embodiment of the present invention, the gear of the first synchronizer 112 is arranged between the second and third converging gears, and the gear of the second synchronizer 116 is arranged between the fourth and fifth converging gears.

[0058]According to yet another preferred embodiment of the present invention, the case body 121 and the planet carrier 123 are respectively provided with teeth that can be connected with the L / H shift synchronizer 122 .

[0059] According to yet another preferred embodiment of the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com