Processing method and matching gear wheel of ultrahigh-precision complex curve rack

A complex curved surface, ultra-high technology, used in belts/chains/gears, components with teeth, portable lifting devices, etc. Accuracy, elimination of backlash, effects of high-precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

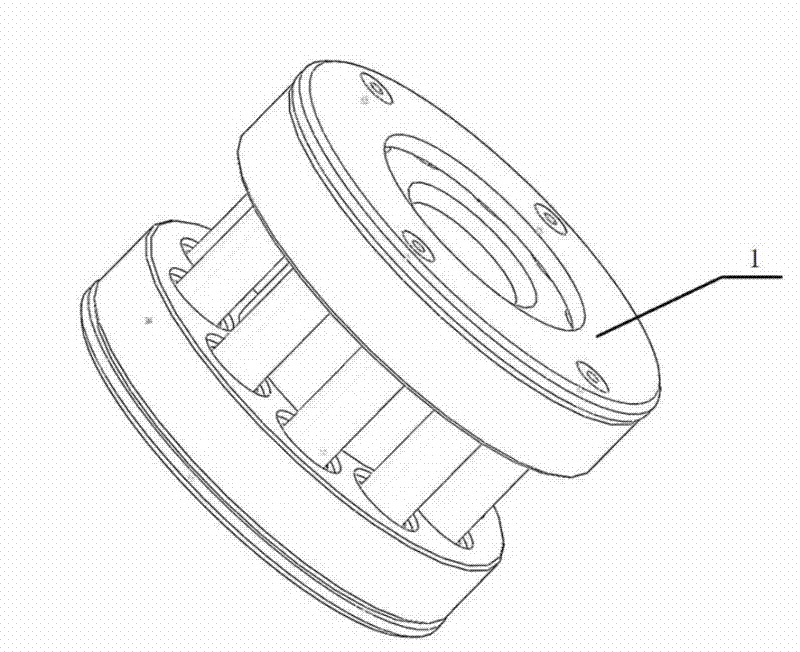

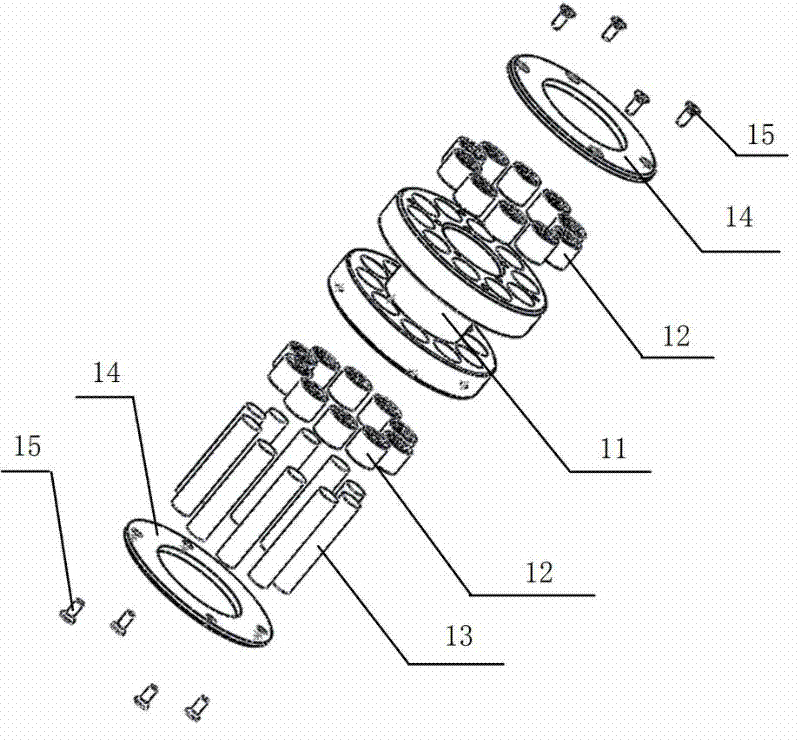

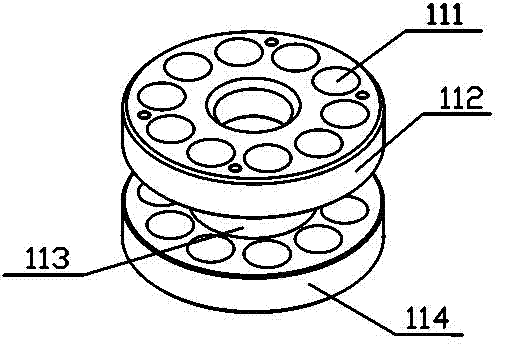

[0049] like figure 1 , figure 2 An ultra-high-precision gear 1 shown includes: a wheel frame 11 , a bearing 12 , a round roller 13 and a stopper 14 . Described wheel skeleton 11 is I-shaped (as image 3 As shown), it is composed of an upper end surface 112 , a lower end surface 114 and an intermediate connecting column 113 , and the intermediate connecting column 113 is located between the upper end surface 112 and the lower end surface 114 .

[0050] The above-mentioned components are connected in the following way: the upper end face 112 and the lower end face 114 of the wheel frame 11 are provided with fixing holes 111, and the upper end face 112 and the lower end face 114 are provided with fixed holes of the same size on the same position in the axial direction; the bearing 12 is fixed In the fixing hole 111 , the round roller 13 is fitted in the bearing 12 . The bearings 12 are in a group of 10, and each fixing hole is equipped with a bearing, and the fixing hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com