A track slag removal device for track paver on cement concrete pavement

A cement concrete, track-type technology, applied in track cleaning, cleaning methods, construction, etc., can solve problems affecting track flatness, wheel wear, and pavement flatness, etc., and achieve the effect of extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. For ease of description, set the forward direction of the paver as the front, and the opposite direction as the rear.

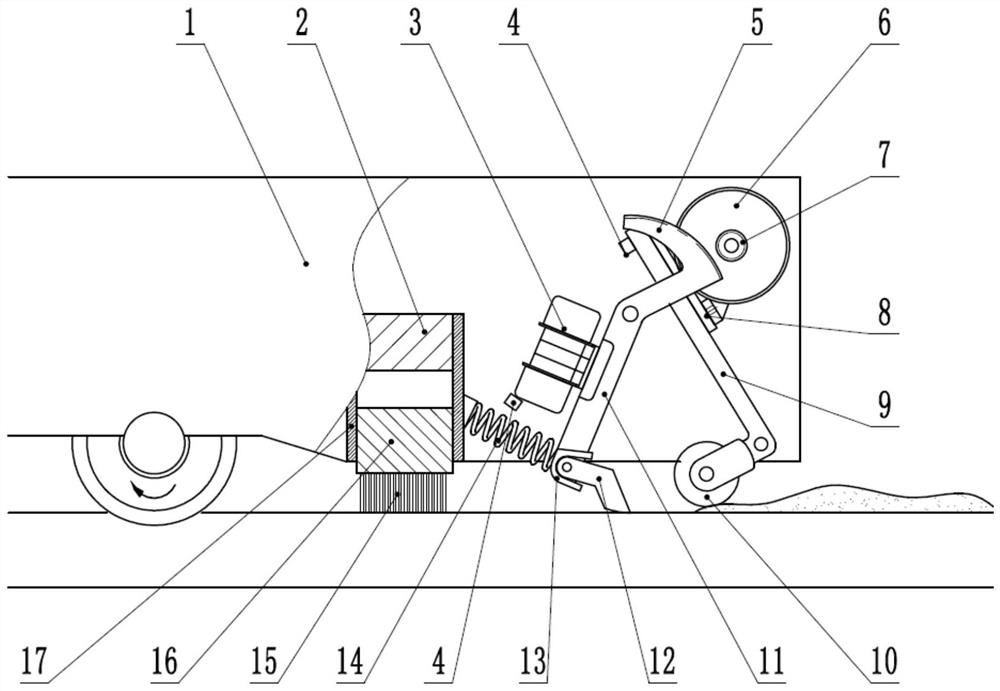

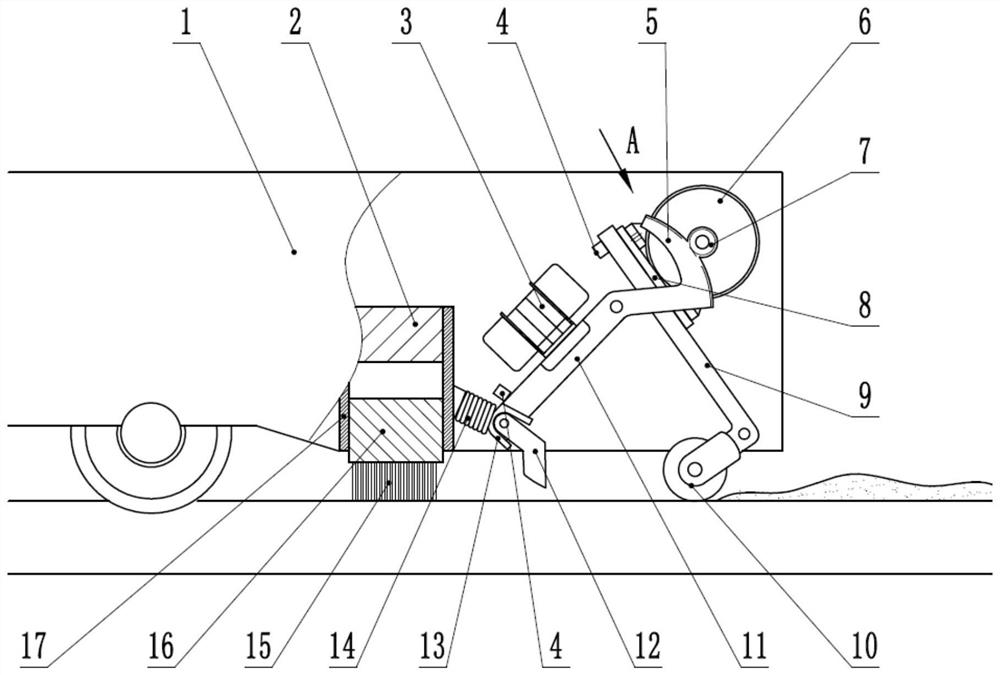

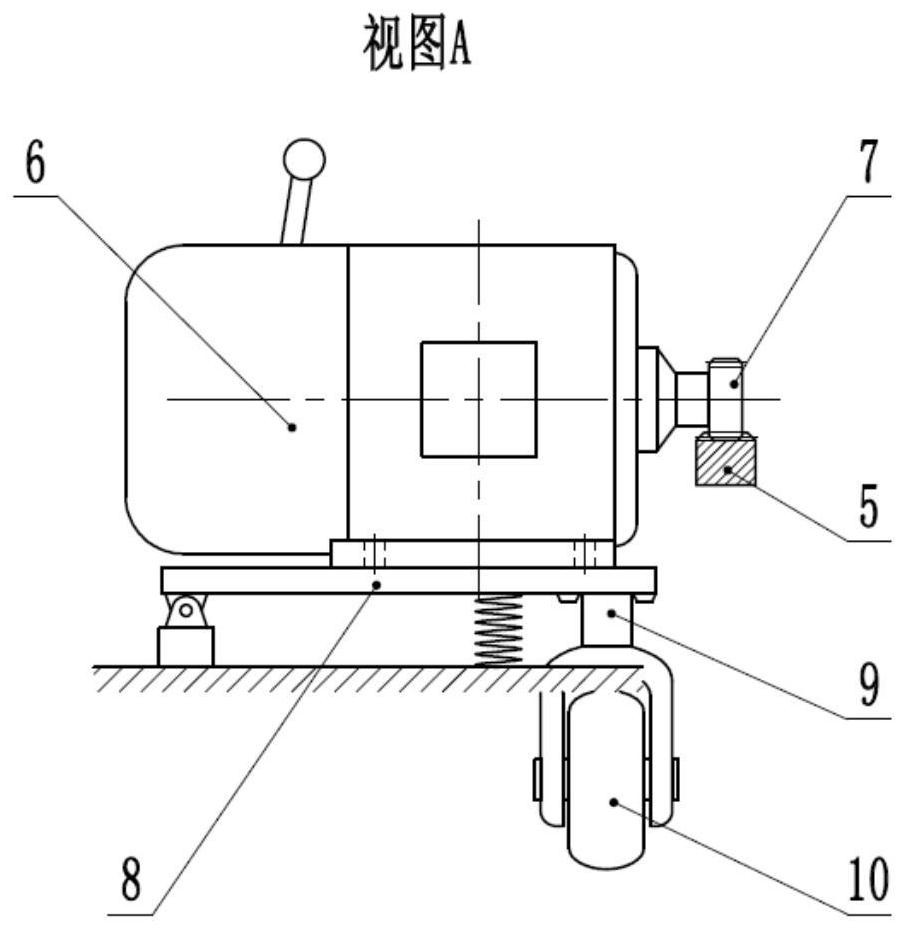

[0018] Such as Figures 1 to 4 As shown, the present invention includes a slag pusher, a rail sweeper, a thrust spring 14, a brake motor 6 and an L-shaped bar 9.

[0019] The L-shaped rod 9 includes a long arm and a short arm, the short arm is inclined from the back down to the front up, the long arm is inclined from the front down to the back up, the upper end of the short arm is fixedly connected to the lower end of the long arm, The connection forms a corner, and the corner of the L-shaped bar 9 is hinged with the car body 1 . The lower end of the short arm of the L-shaped bar 9 is provided with a wheel 10, and the wheel 10 is positioned on the track. When there is cement slag on the track, the wheel 10 is upwardly jacked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com