Device and method for testing hot crack of aluminum alloy under condition of active applied load

A technology of applying load and testing experiments, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems that there is no one type and the equipment cannot meet the requirements, etc., and achieve simple operation, rich types of test equipment, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

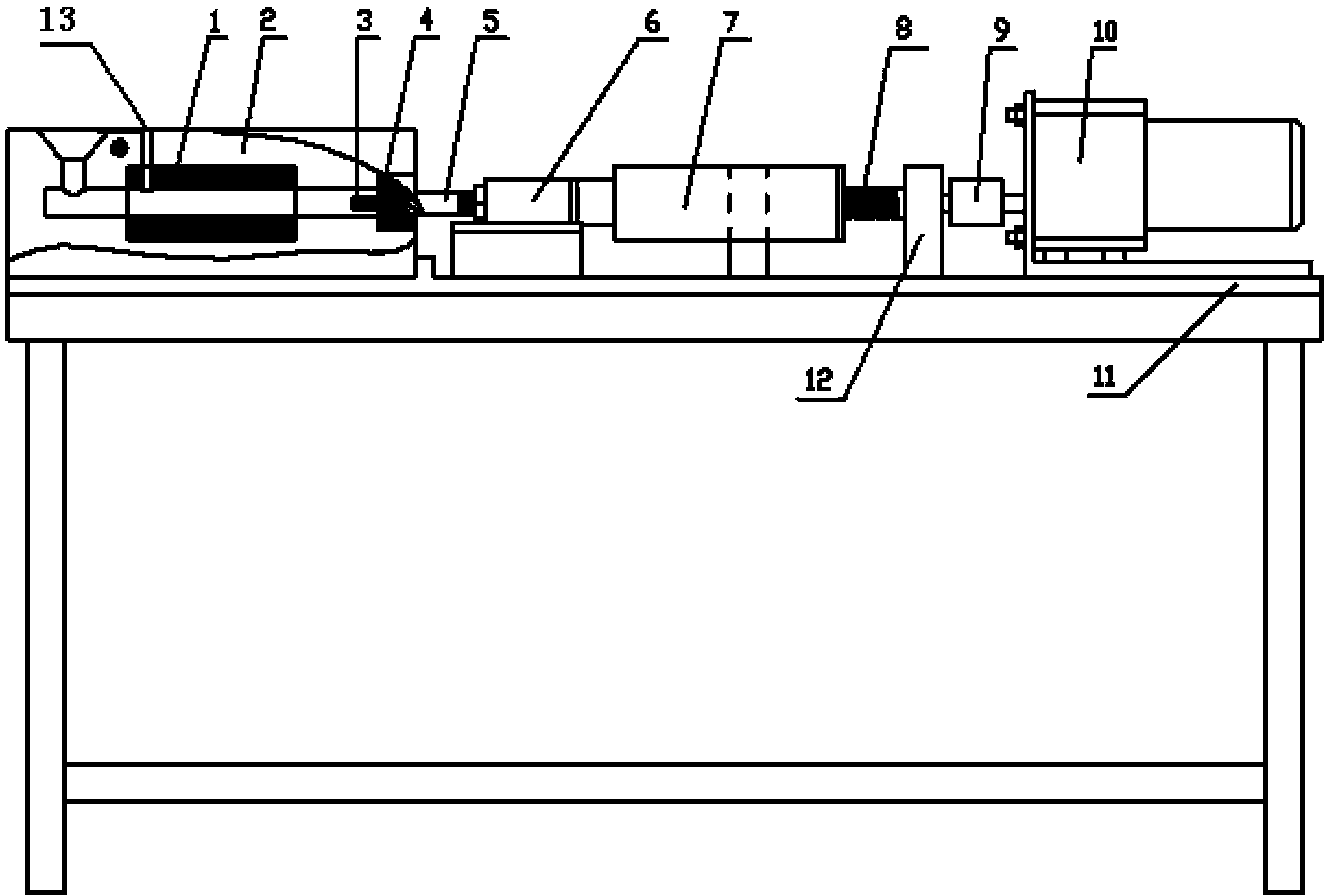

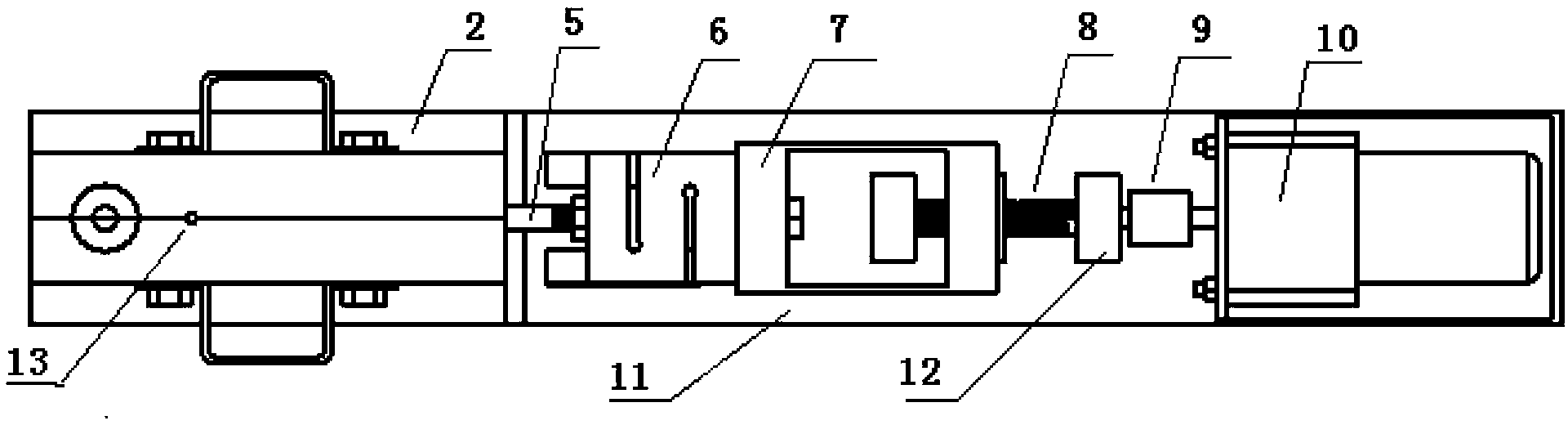

Method used

Image

Examples

Embodiment 1

[0043] (1) Materials used in the experiment: A356 alloy (the alloy composition is shown in Table 1), graphite insulation material, Al-10%Sr

[0044] Modifier, Al-5%Ti-1%B refiner, DSG aluminum alloy slag and degasser, paint.

[0045] Chemical composition (wt%) of table 1A356 alloy

[0046]

[0047] (2) Instruments and equipment used in the experiment: intermediate frequency furnace, 12KW resistance furnace, active load thermal cracking test device, TP1000 paperless recorder, "K" type nickel-chromium-nickel-silicon thermocouple.

[0048] (3) Preparations before the experiment:

[0049] ① Before the experiment, check whether the paperless recorder, speed-regulating motor, tension-pressure sensor, "K" type nickel-chromium-nickel-silicon thermocouple and other components are working normally.

[0050] ②Adjust the connecting screw to the initial position, and tighten the full-thread screw at the end of the connecting screw.

[0051] ③ Mix the paint used in the experiment, the...

Embodiment 2

[0065] Concrete experimental procedure sees embodiment 1 for details, difference: the thermal insulation material used inside the metal mold cavity is changed into riser thermal insulation material by graphite thermal insulation material; Insulation bricks are used around the mold for insulation; the horizontal loading speed is controlled at 0.15mm / s.

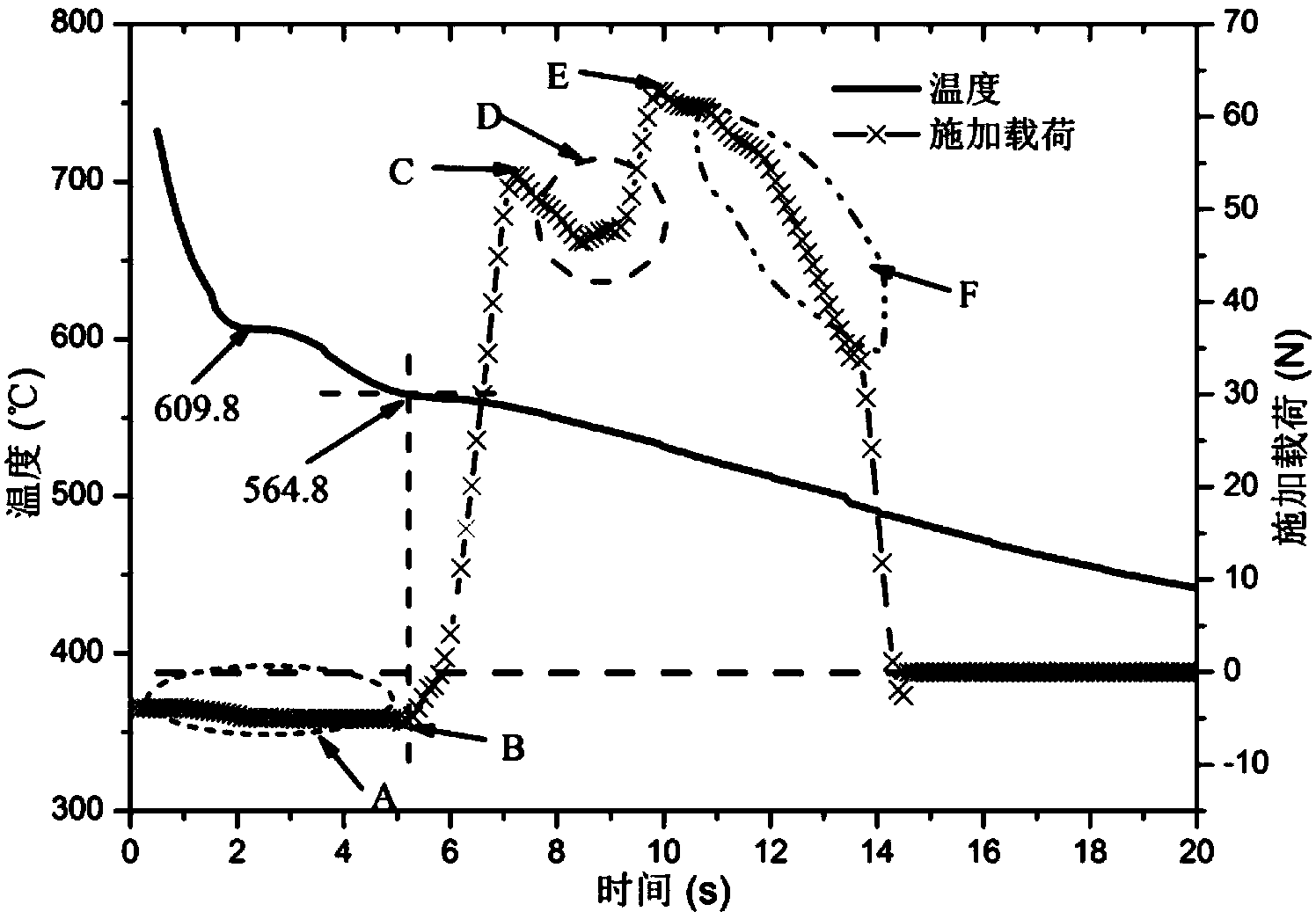

[0066] The measured temperature and applied load curves are shown as Figure 4 shown. In this embodiment, due to the reduction of the overall cooling rate of the metal mold, the experimentally measured primary crystal phase temperature (615.5°C) and eutectic temperature (576°C) are closer to the theoretical temperature of the alloy. It can be seen from the curve of the applied load that there are 3 characteristic points and 3 characteristic regions similar to Example 1. The critical load values of the two examples cracked at high temperature are different. This is mainly due to the fact that the overall cooling rate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com