Polysilicon preparation apparatus and method

A polysilicon preparation and amorphous silicon layer technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve the problems affecting the electron mobility of polysilicon, small grains, and many grain boundaries between grains. Achieve the effect of increasing electron mobility and increasing size

- Summary

- Abstract

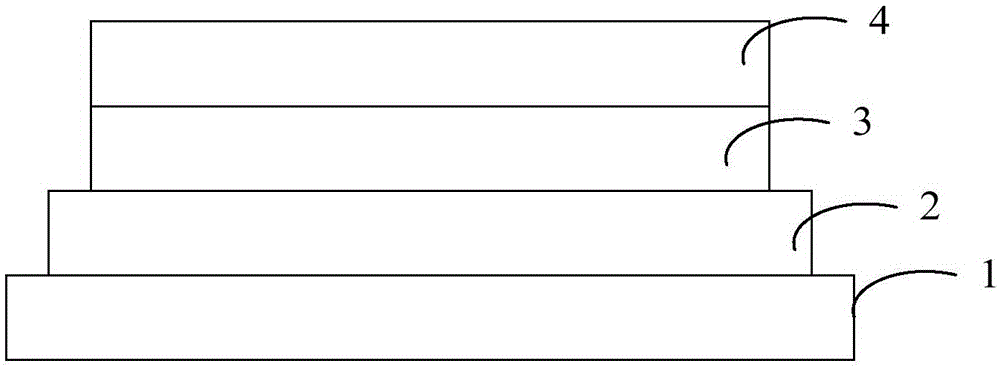

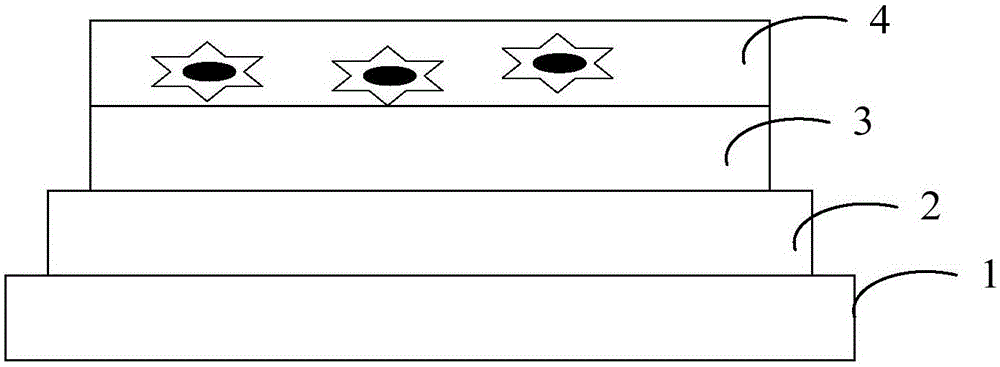

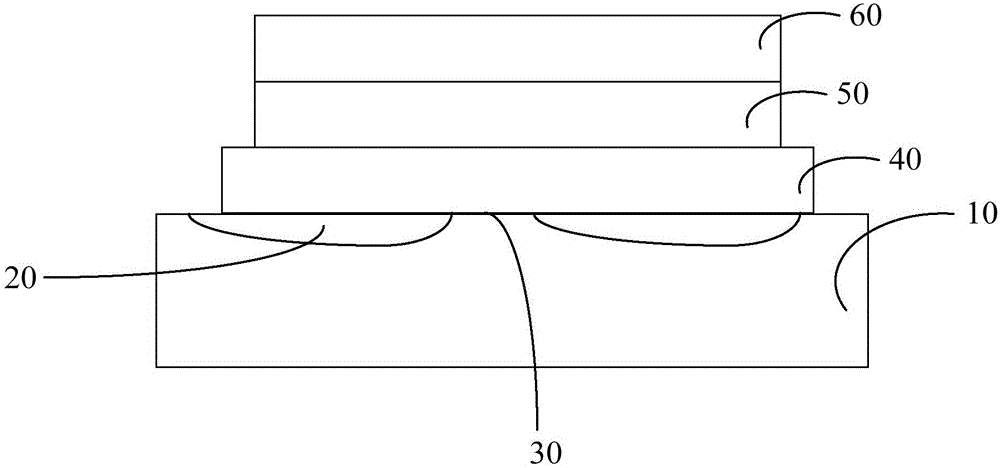

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The word "embodiment" used in this specification means serving as an example, example, or illustration. In addition, the article "a" used in this specification and the appended claims can generally be interpreted as meaning "one or more" unless specified otherwise or clearly directed to the singular form from the context.

[0032] In the present invention, a plurality of mirrors and a diffuse reflection layer are provided on the surface of the support platform. The diffuse reflection layer is provided between the mirror and the mirror, and when laser annealing is performed, the diffuse reflection layer penetrates the non When the laser of the crystalline silicon layer is irradiated on the diffuse reflection layer area, diffuse reflection occurs; when irradiated on the mirror area, the reflected laser energy is concentrated on the amorphous silicon layer, so that the amorphous silicon in the area can be It absorbs energy and forms an energy gradient with other areas. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com