Microstructure biological material directional cooling preparation device

A technology of biological materials and preparation devices, which is applied in the direction of household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc., can solve the problem that the cooling device cannot guide the cooling material cooling speed in a directional way, and achieve the adjustable cooling speed and cooling process , easy to control, increase the effect of conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

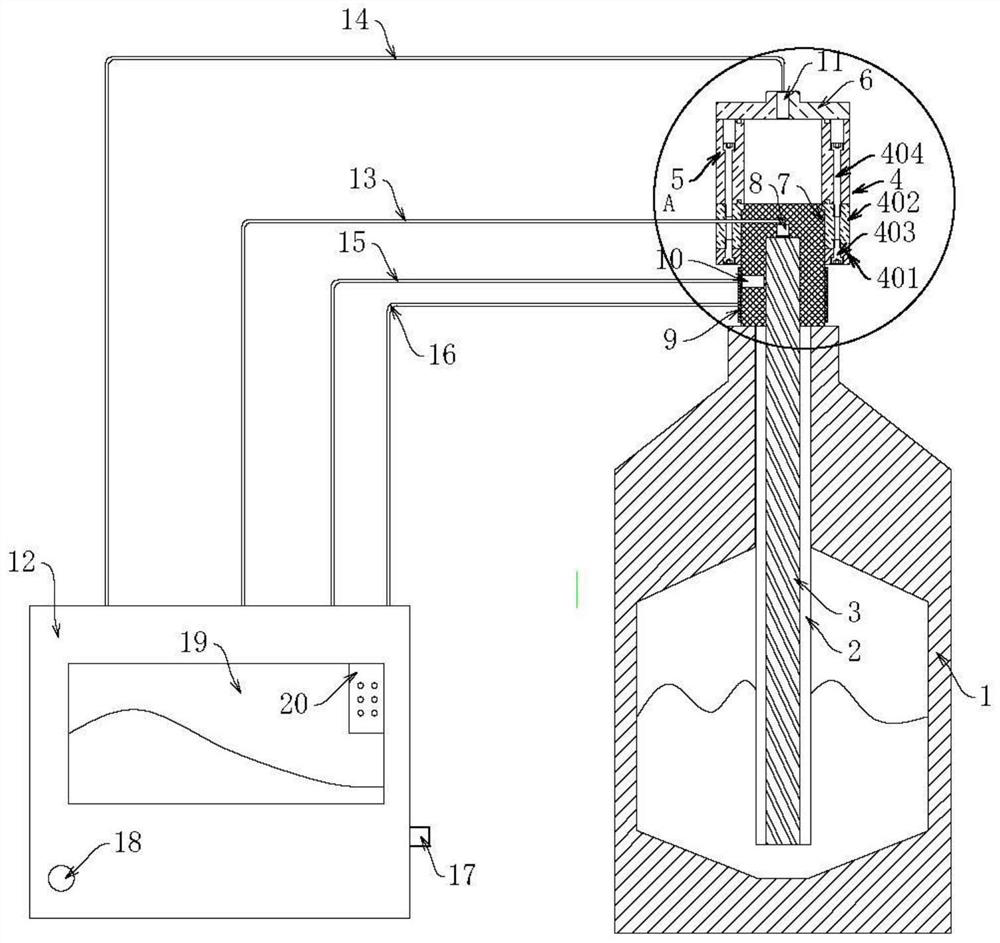

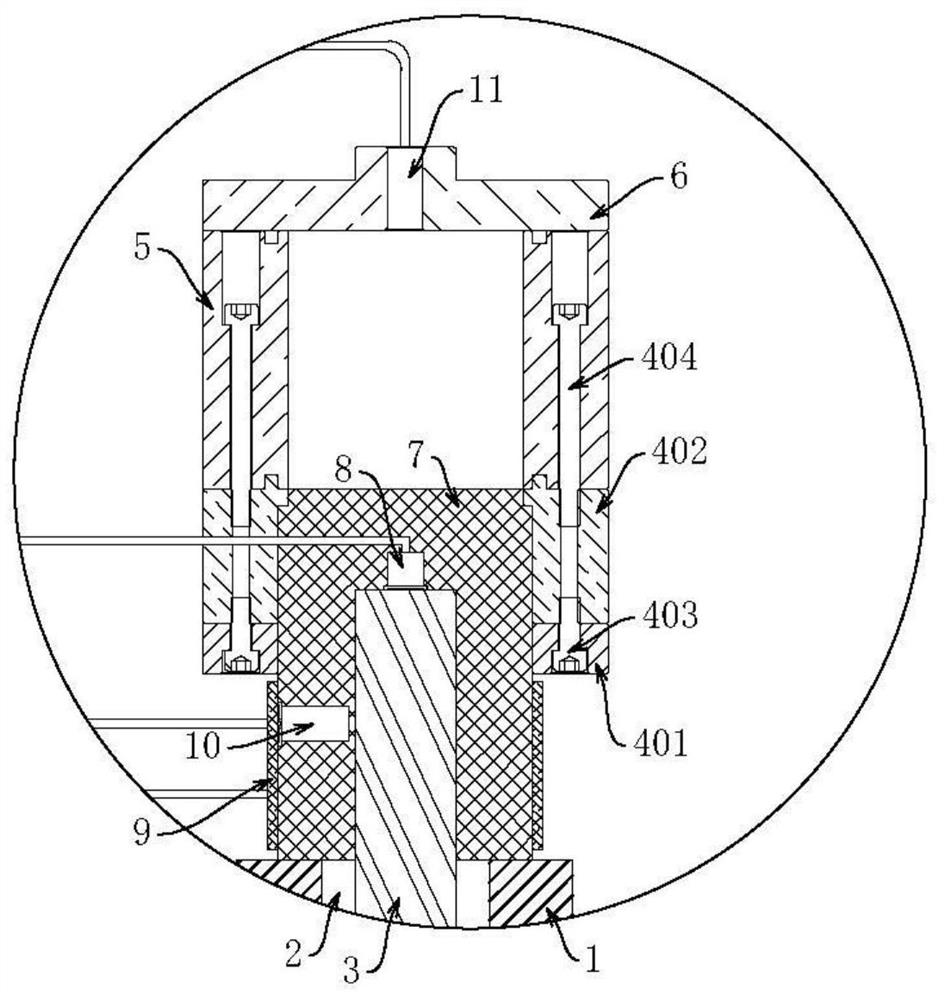

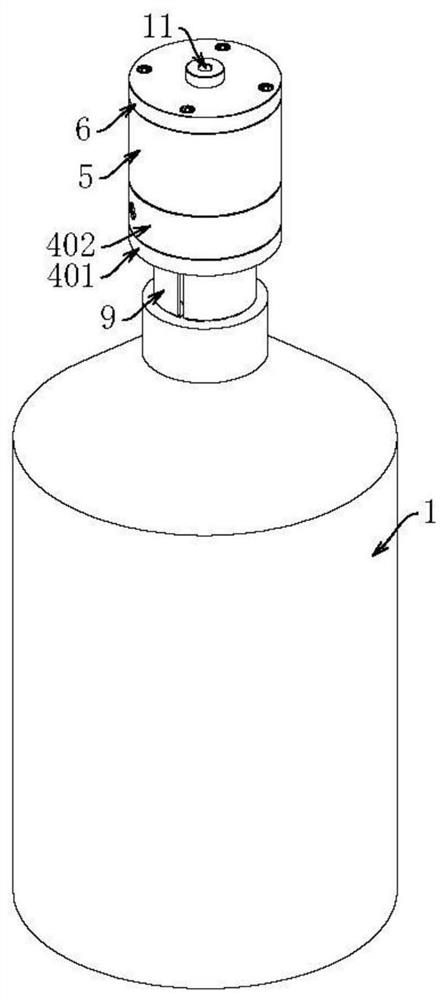

[0031] A preparation device for directional cooling of microstructured biological materials, comprising a cold source tank 1, the cold source can be liquid nitrogen, and the cold source tank 1 is provided with a placement cylinder 2, the placement cylinder 2 is a cavity structure with one end closed and one end open, for placing A part of the tube 2 can be fixed on the inner wall of the cold source tank 1 by welding, but the other part of the tube 2 is suspended in the cold source tank 1, and one end of the tube 2 extends to the cold source tank 1 At the opening of the placement cylinder 2, a cooling mechanism including the first cooling column 3 is fixed, the first cooling column 3 can be fixedly connected to the placement cylinder 2 by but not limited to welding, the first cooling column 3 One end extends to the outside of the cold source tank 1 and is inserted into the sealing member 4. The sealing member 4 is arranged at the opening of the cold source tank 1 and seals the c...

Embodiment 2

[0035]This embodiment is a continuous improvement on the basis of Embodiment 1. On the basis of the technical solution of the embodiment, the first temperature sensor 8 is provided at the end of the first cold guide column 3 outside the cold source tank 1, and the second guide column 3 is provided with a first temperature sensor 8. The outer wrapping of cold column 7 is provided with heating ring 9, and the side of heating ring 9 close to the second cooling column 7 is fixedly provided with heating temperature sensor 10, and heat preservation cover 6 is provided with the second temperature sensor 11 that penetrates, and the first temperature sensor 8. The second temperature sensor 11, the heating temperature sensor 10, and the heating ring 9 are electrically connected to the corresponding corresponding parts of the console 12 through the first temperature sensing line 13, the second temperature sensing line 14, the heating temperature sensing line 15, and the heating power line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com