A kind of ultrafine nano silver wire dispersion liquid and preparation method thereof

A technology of ultra-fine nano and dispersion liquid, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high repeatability, low cost, good stability, etc., and achieve increased solubility , reduce viscosity, strong wettability of solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of ultrafine nano silver wire dispersion, comprising the following steps:

[0031] (1) Prepare the following solution:

[0032] Solution A: prepare a polyol solution of silver nitrate, and then add water;

[0033] Solution B: prepare a polyol solution of polyvinylpyrrolidone and polyethylene glycol, and then add water;

[0034] Solution C: prepare a mixed aqueous solution of platinum chloride and sodium chloride;

[0035] D solution: prepare an aqueous or alcoholic solution of anionic surfactant;

[0036] (2) Add solution A to solution B under stirring conditions to obtain a mixed solution of AB. After the mixed solution of AB is stirred uniformly, solution D is added to the mixed solution of AB, and the mixed solution of ABD is obtained by stirring uniformly, and then added to the mixed solution of ABD. Slowly add C solution dropwise and stir to obtain ABDC mixed solution;

[0037] (3) Pour the ABDC mixed solution obtained in step (2) into the ...

Embodiment 1

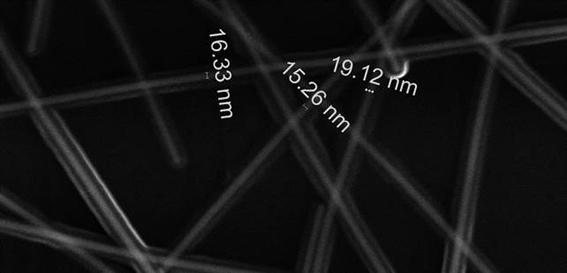

[0048] This embodiment provides a method for preparing nano-silver wires with a diameter of 22-30 nm, which is as follows

[0049] Dissolve 0.068g silver nitrate in 50ml polyol solution, prepare the polyol solution of silver nitrate, then add 20ml deionized water and 1ml DMF to the aforementioned polyol solution of silver nitrate, and prepare solution A;

[0050] Dissolve 0.011g PVPk90 and 0.4g PEG4000 in 50ml polyol solution to prepare a polyol solution of polyvinylpyrrolidone and polyethylene glycol, then add 20ml deionized water to the polyol solution of polyvinylpyrrolidone and polyethylene glycol, Formulated into B solution;

[0051] Dissolve platinum chloride and sodium chloride in 1 L of deionized water to obtain a C solution with a total chloride ion concentration of 0.01 mol / L, wherein the molar concentration of platinum chloride is 0.003 mol / L, and the molar concentration of sodium chloride is 0.004 mol / L;

[0052] Dissolve 0.876g of sodium dodecyl sulfonate in 1L ...

Embodiment 2

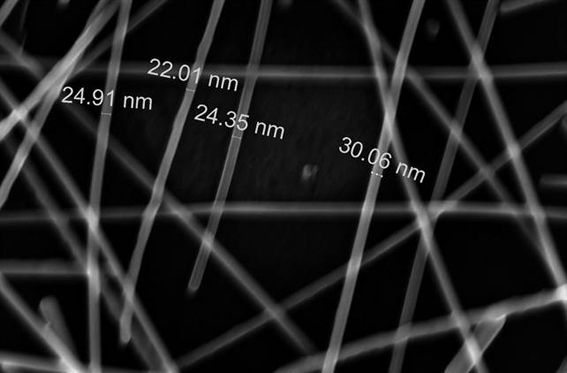

[0057] This embodiment provides a method for preparing nano-silver wires with a diameter of 22-28 nm, which is as follows

[0058] Dissolve 0.085g of silver nitrate in 50ml of polyol solution to prepare a polyol solution of silver nitrate, then add 22.5ml of deionized water and 2.5ml of DMF to the aforementioned polyol solution of silver nitrate to prepare solution A;

[0059] Dissolve 0.14g PVPk90 and 5g PEG4000 in 50ml polyol solution to prepare a polyol solution of polyvinylpyrrolidone and polyethylene glycol, then add 22.5ml deionized water to the polyol solution of polyvinylpyrrolidone and polyethylene glycol, Formulated into B solution;

[0060] Dissolve platinum chloride and sodium chloride in 1 L of deionized water to obtain a C solution with a total chloride ion concentration of 0.1 mol / L, wherein the molar concentration of platinum chloride is 0.01 mol / L and the molar concentration of sodium chloride is 0.08 mol / L;

[0061] Dissolve 3.69g of fatty acid sodium in 1L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com