Zoom lens module

A zoom lens and lens barrel technology, applied in the field of high-magnification zoom lens modules, can solve the problems of increasing the volume of zoom lens modules, high material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

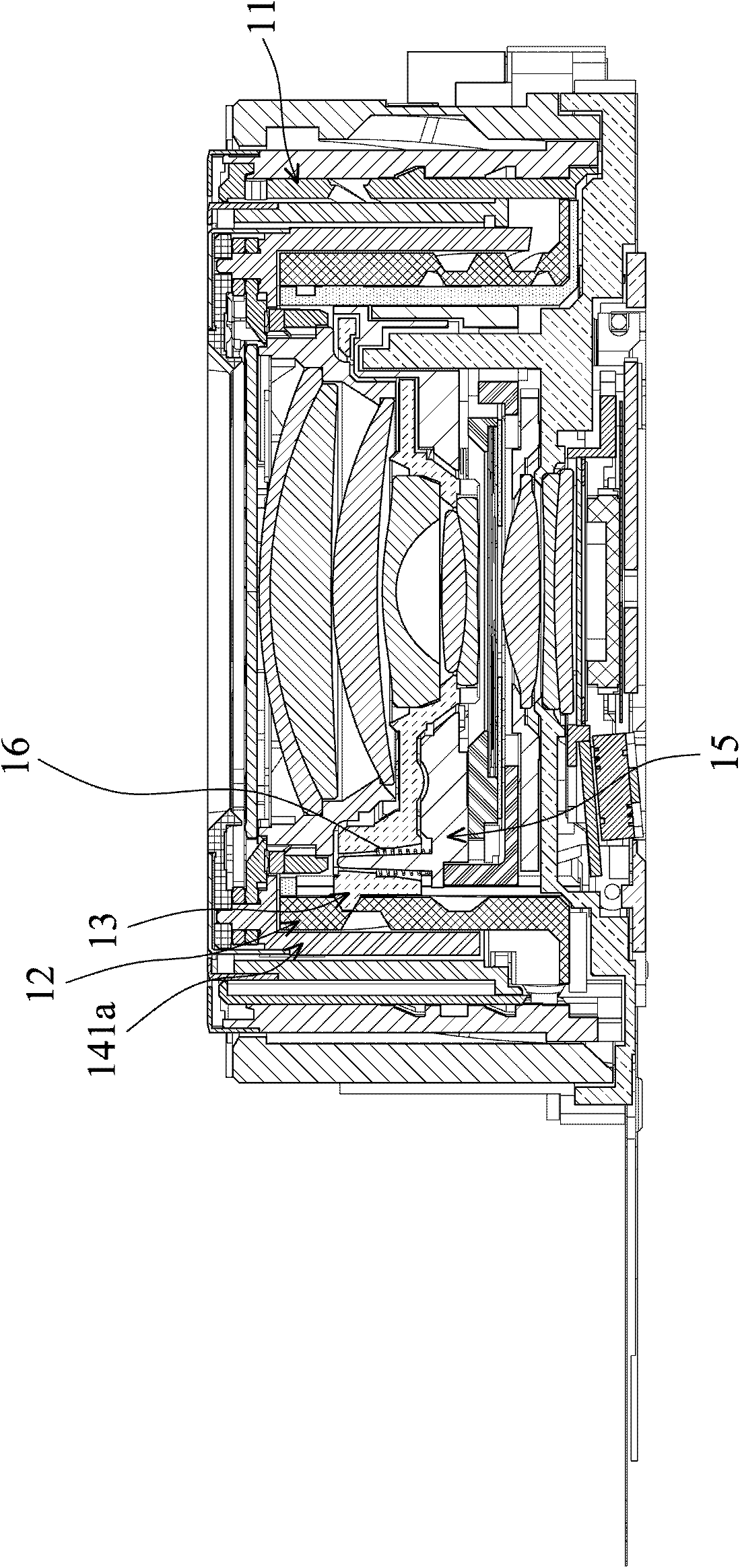

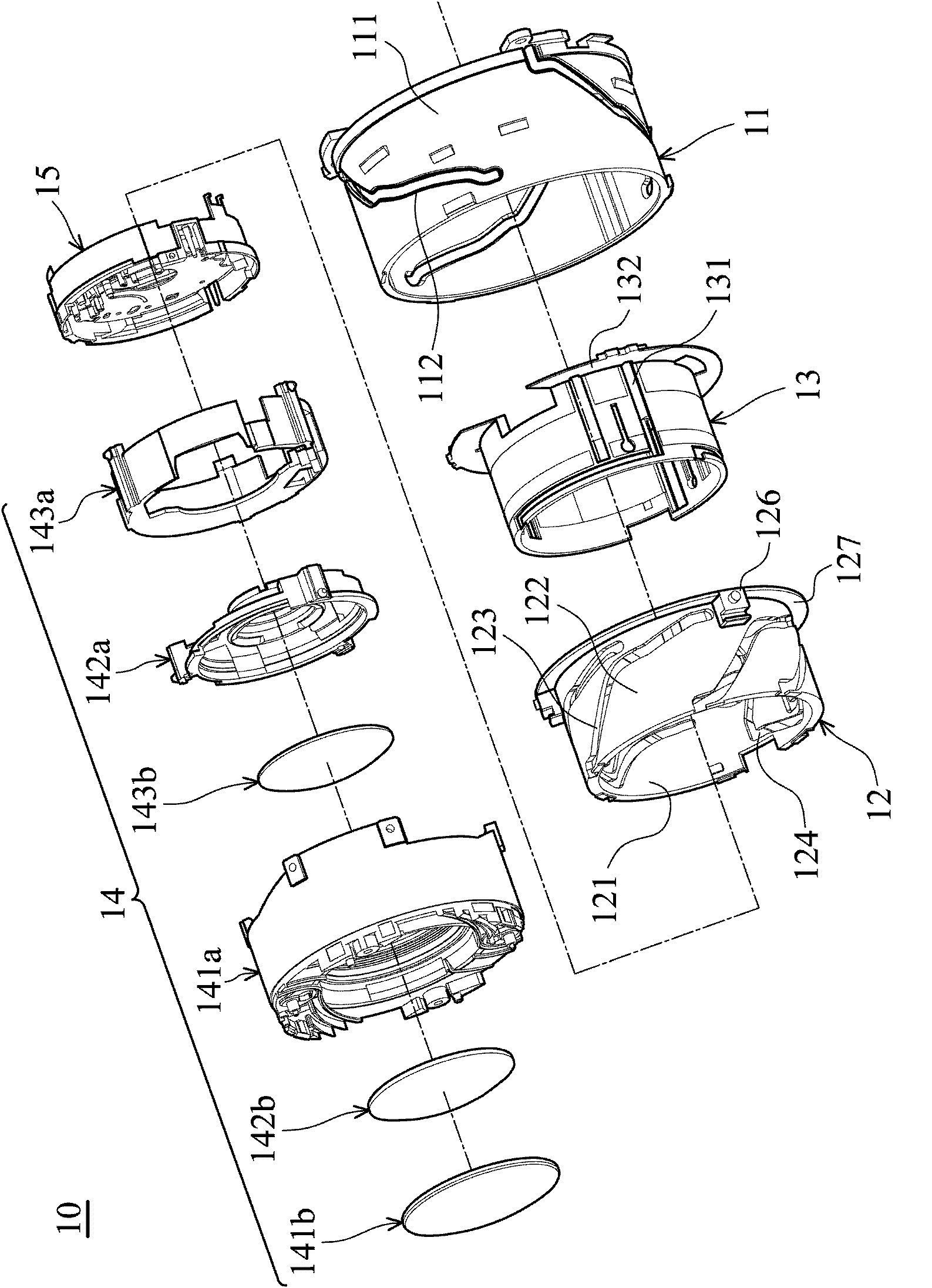

[0020] Figure 1a is a schematic cross-sectional view of the zoom lens module of the present invention, Figure 1b It is an exploded schematic diagram of the zoom lens module of the present invention; it should be noted that in Figure 1b In, only means Figure 1a Some components in .

[0021] see Figure 1a , 1b , the zoom lens module 10 mainly includes an inner barrel 11 , a lens barrel 12 , a straight-forward barrel 13 , a lens group module 14 and a shutter 15 .

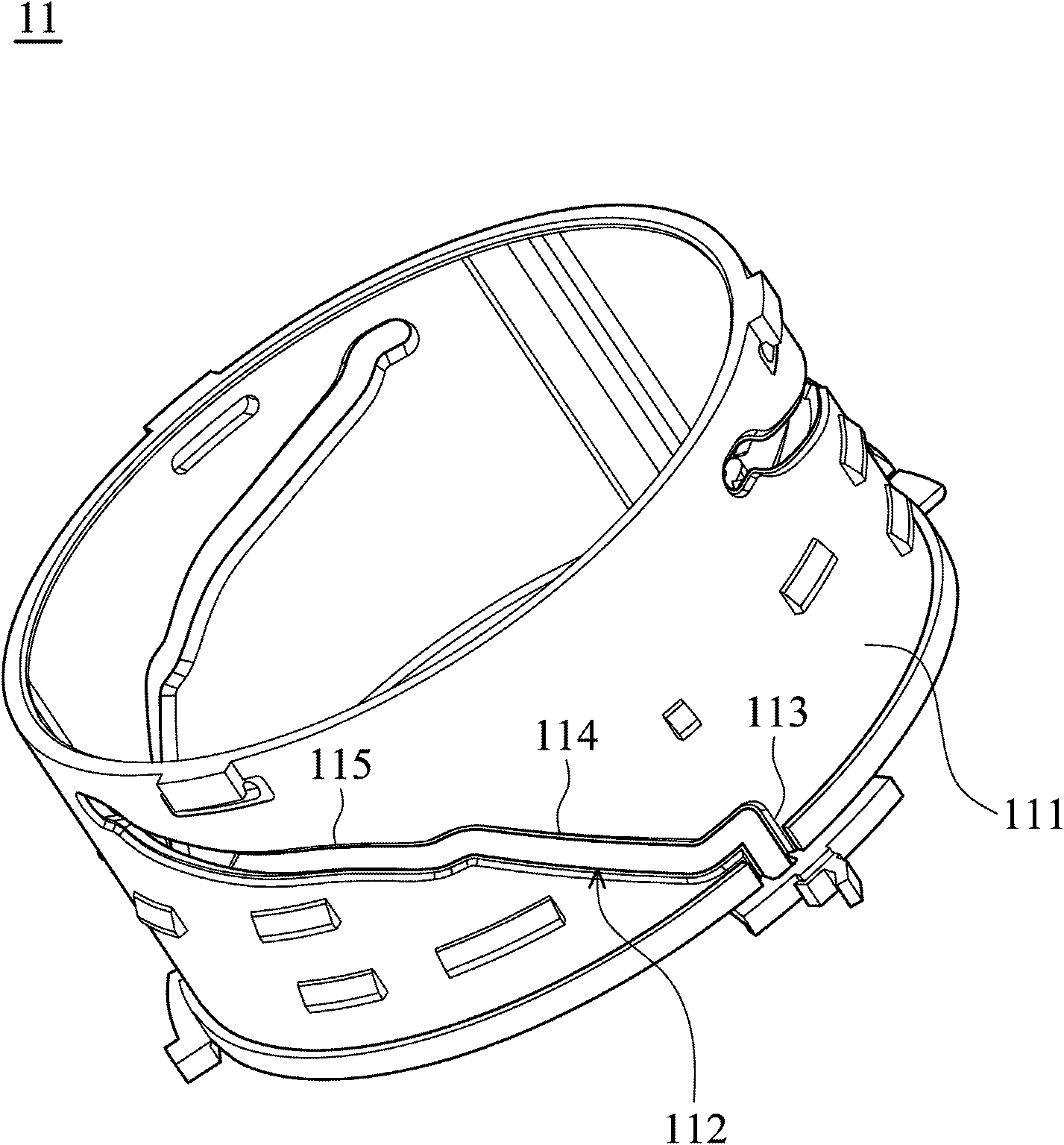

[0022] figure 2 It is a schematic diagram of the inner barrel of the zoom lens module of the present invention. image 3 It is a flattened plan view of the inner barrel of the zoom lens module of the present invention.

[0023] Please refer to figure 2 , 3 , the inner cylinder 11 includes an annular wall 111 and a first moving groove 112, the first moving groove 112 is arranged on the annular wall 11 and includes a positioning section 113, a telescopic section 114 and a compensation section 115, the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com