Reactor and power converter using the same

A technology of reactance and summation, applied in the field of power conversion devices, can solve the problems of reactance device loss, Joule heat, etc., and achieve the effect of suppressing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

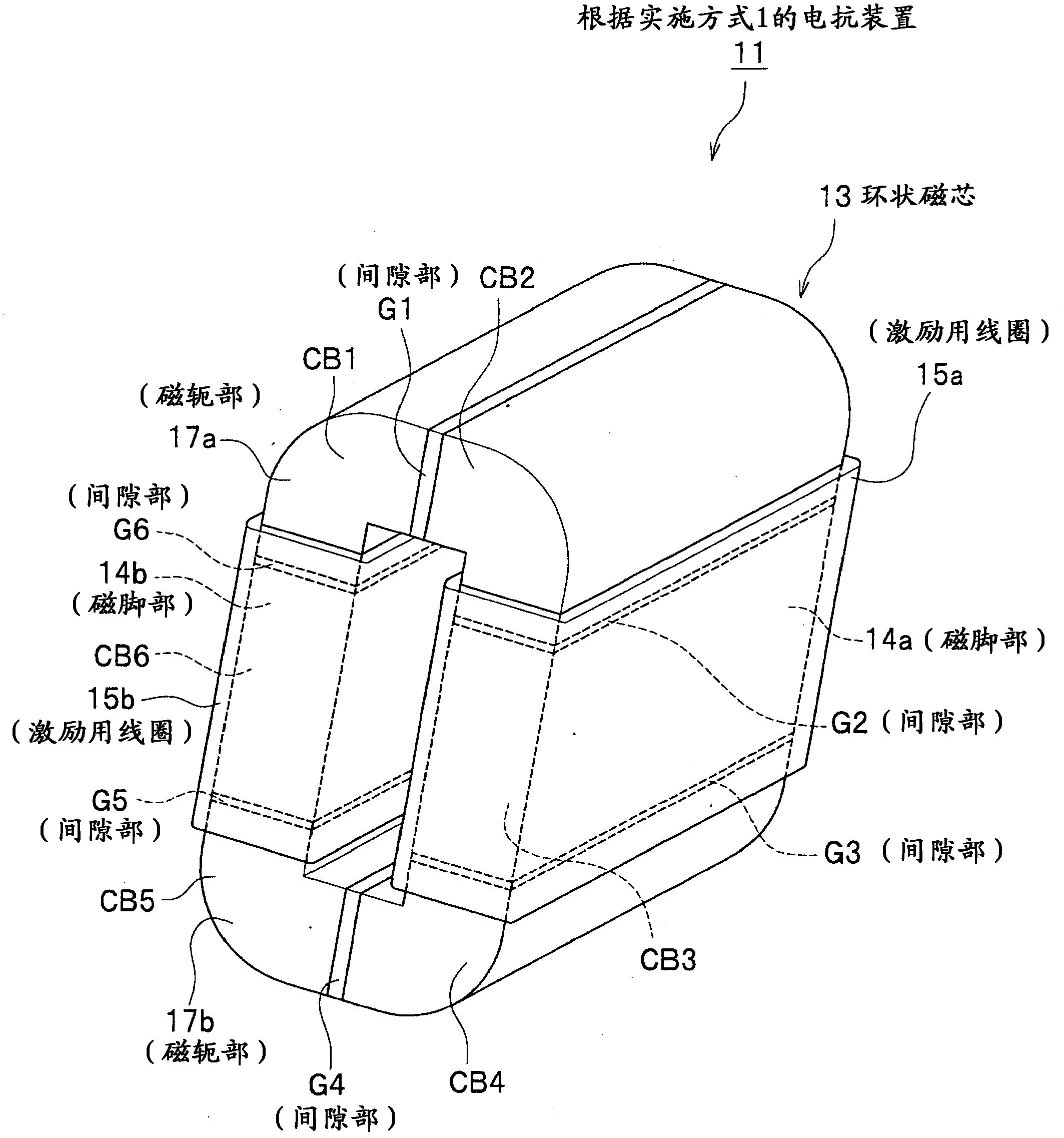

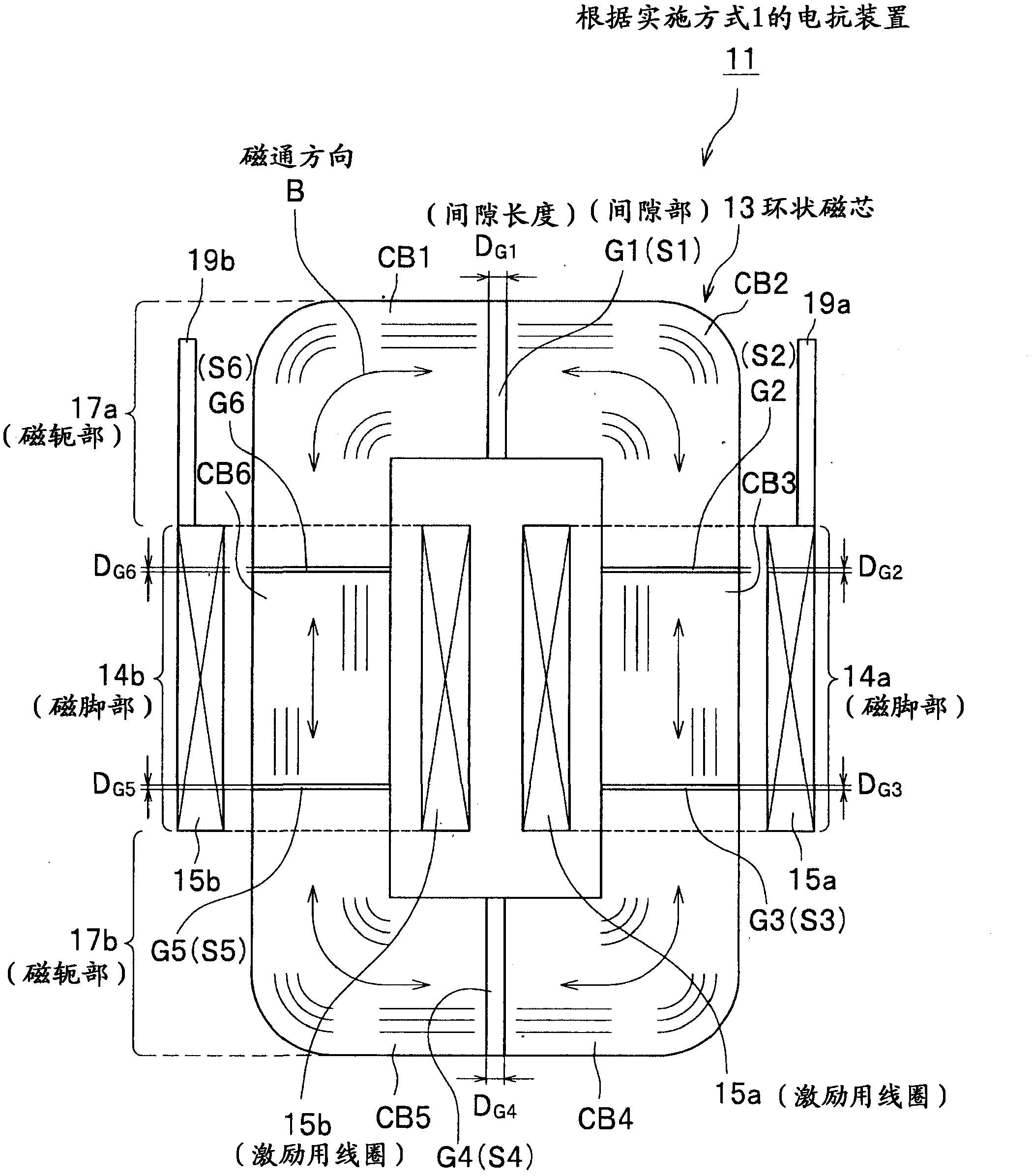

[0025] Figure 1A is an overall perspective view of the reactance device according to Embodiment 1 of the present invention. Figure 1B is a front cross-sectional view of the reactor according to Embodiment 1 of the present invention. exist Figure 1A and Figure 1B In, for example, the term "(magnetic leg)" in parentheses after the reference numeral 14a indicates that the component of the reference numeral 14a, that is, the "first magnetic leg 14a" is the same as the term "magnetic leg" in the claims. correspond. As for other components other than the reference numeral 14a, the above-mentioned notation method is also followed. in addition, Figure 1A and Figure 1B Other drawings other than , also follow the above-mentioned marking method.

[0026] According to the reactance device 11 according to Embodiment 1 of the present invention, even when there are gaps G2, G3, G5, and G6 in the region of the annular core 13 around which the excitation coil 15 is wound, the magneti...

Embodiment approach 2

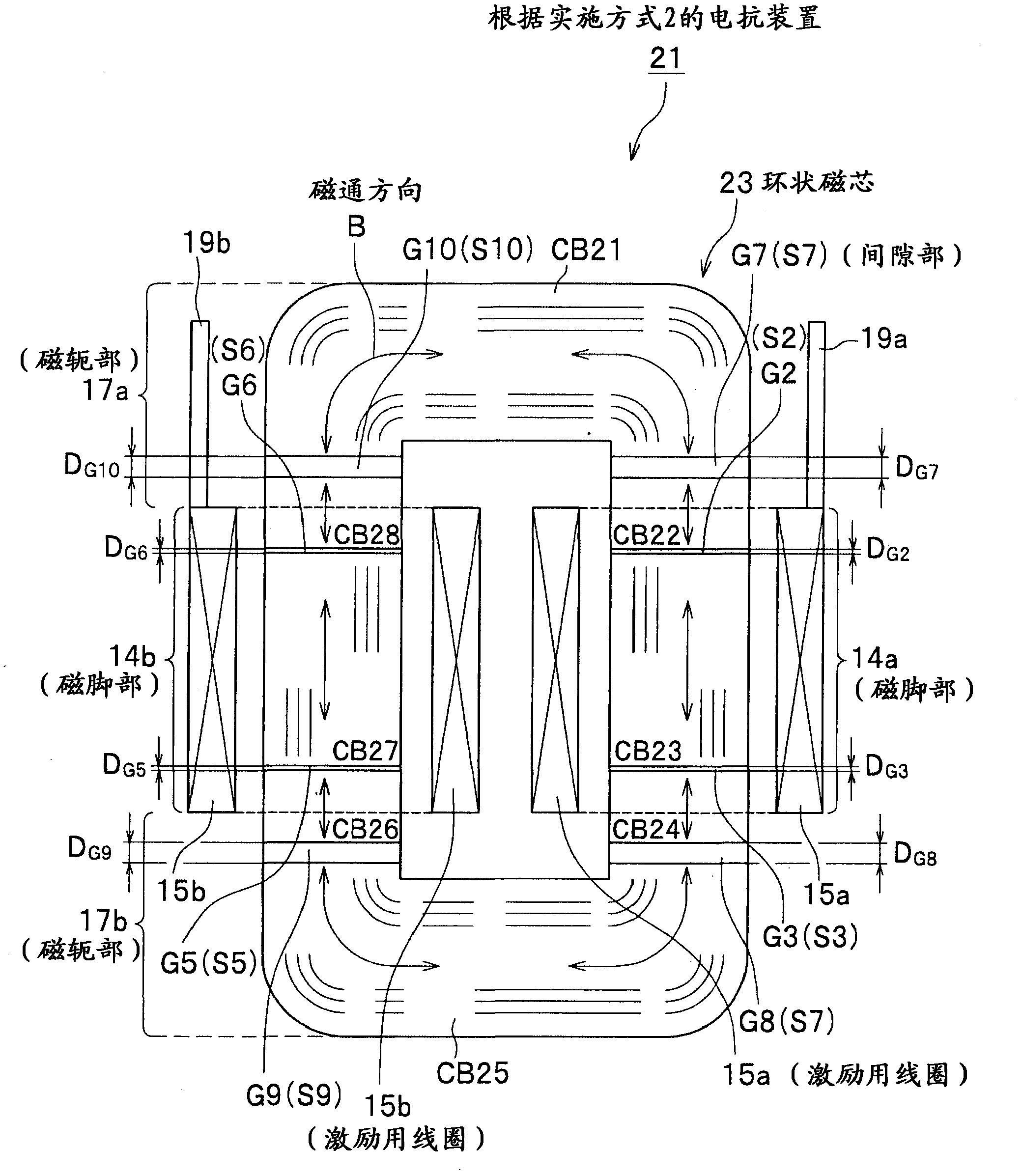

[0054] Next, a reactance device 21 according to Embodiment 2 of the present invention will be described with reference to the drawings. figure 2 It is a front cross-sectional view of the reactance device 21 according to Embodiment 2 of the present invention. The reactance device 11 according to the first embodiment has the same basic constituent elements as the reactance device 21 according to the second embodiment. Therefore, the same reference numerals are assigned to members having the same functions, their repeated descriptions are omitted, and the differences between them will be described.

[0055] Differences between Embodiment 1 and Embodiment 2 are as follows.

[0056] That is, when the toroidal core 13 is viewed on a virtual clock, in the reactance device 11 according to Embodiment 1, it looks like Figure 1A and Figure 1B As shown, a first gap G1 existing in the first yoke portion 17a is provided at the 12 o’clock position, and a fourth gap portion existing in t...

Embodiment approach 3

[0065] Next, a reactance device 31 according to Embodiment 3 of the present invention will be described with reference to the drawings. image 3 is a front cross-sectional view of a reactor 31 according to Embodiment 3 of the present invention. The reactance device 11 according to the first embodiment has the same basic constituent elements as the reactance device 31 according to the third embodiment. Therefore, the same reference numerals are assigned to members having the same functions, their repeated descriptions are omitted, and the differences between them will be described.

[0066] Differences between Embodiment 1 and Embodiment 3 are as follows.

[0067] That is, in the reactor device 11 according to Embodiment 1, the first and second yoke parts 17a, 17b sandwich the first and second magnetic leg parts 14a, 14b and face each other. Figure 1B The paper surface is divided into two in the upper and lower directions. In addition, when the toroidal core 13 is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com