Amorphous alloy three-dimensional rolled iron core capable of reducing noise

A technology of three-dimensional wound iron core and amorphous alloy, applied in the direction of transformer/inductor magnetic core, etc., can solve the problem that the noise of three-dimensional wound iron core of amorphous alloy is difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

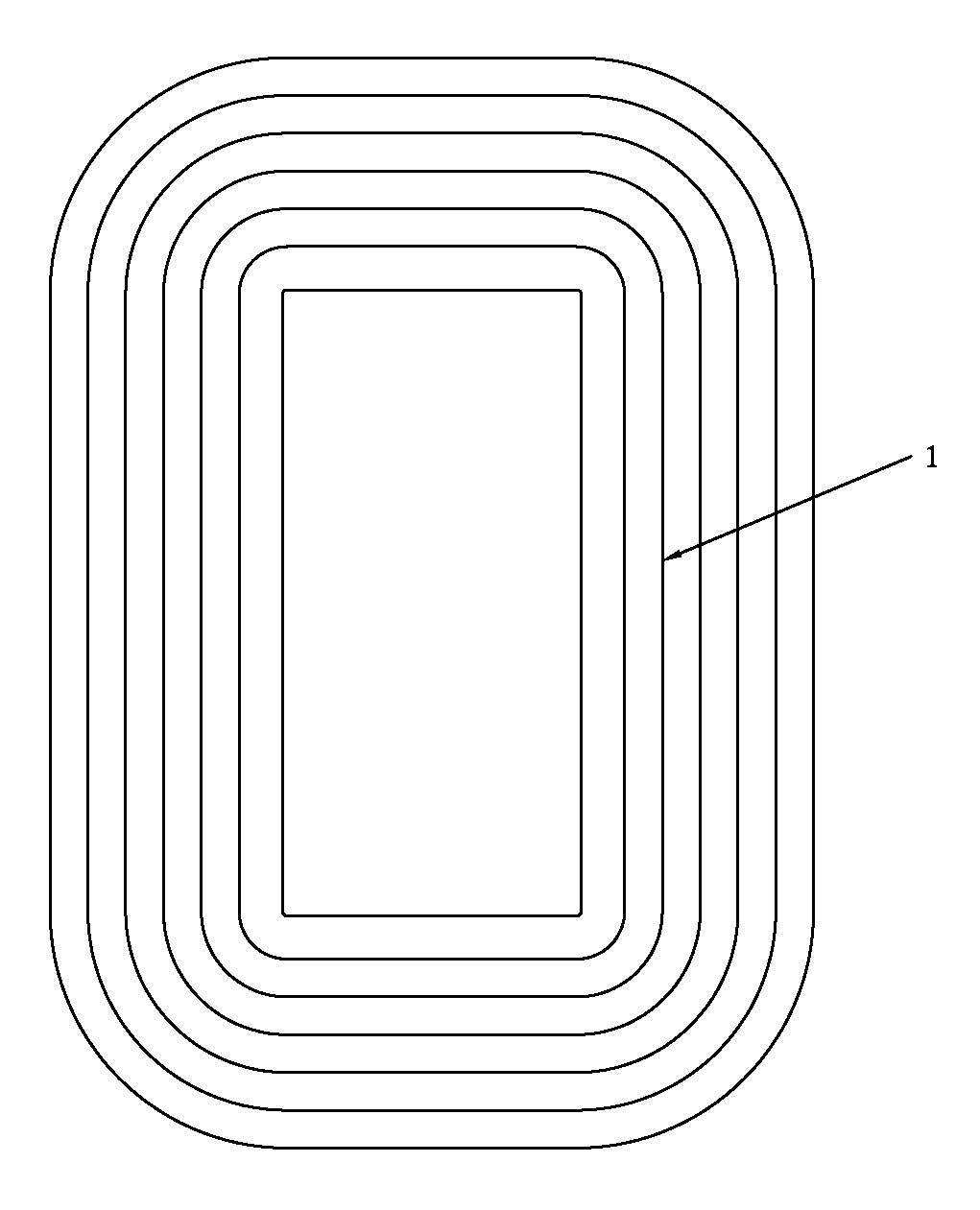

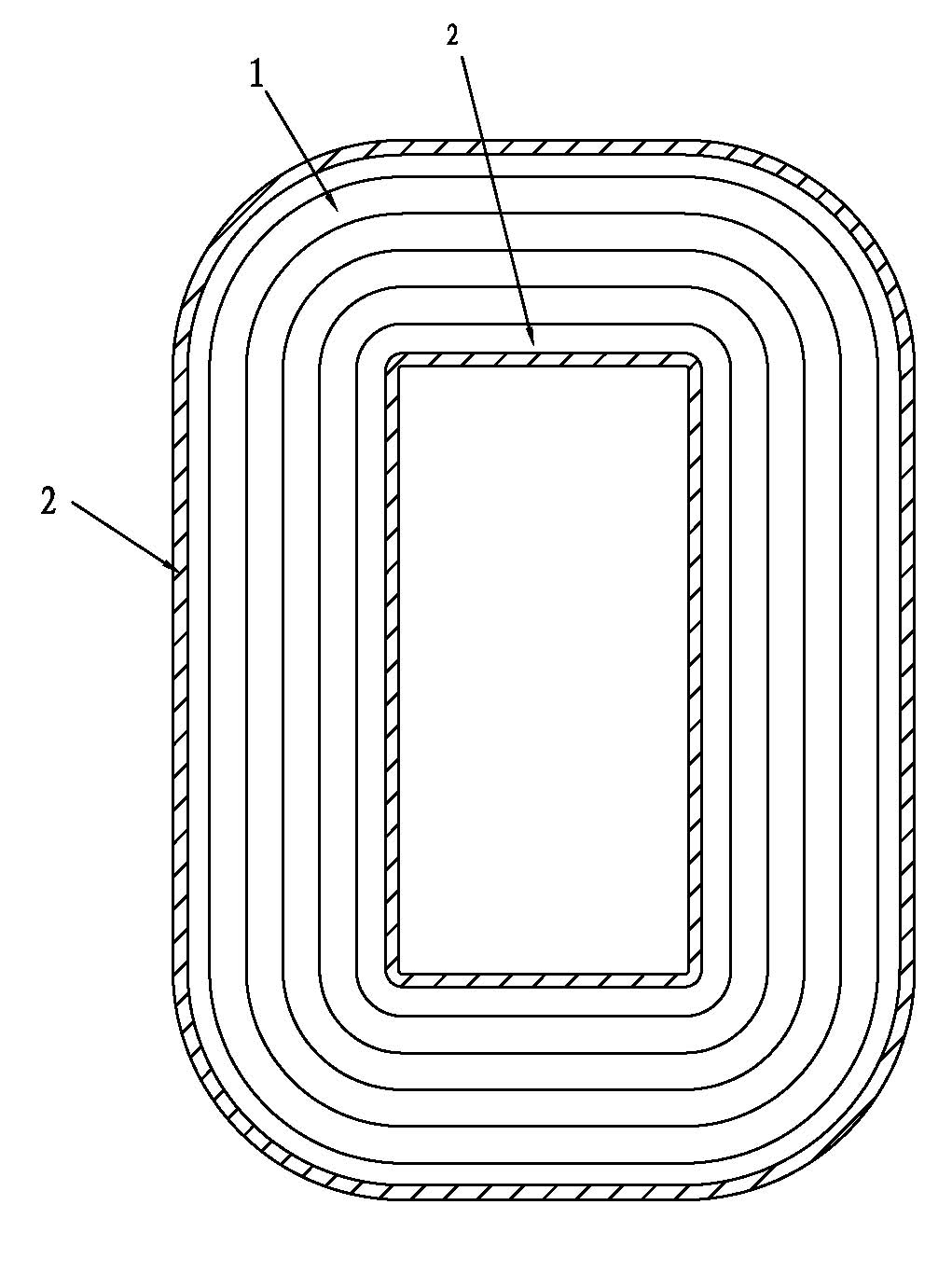

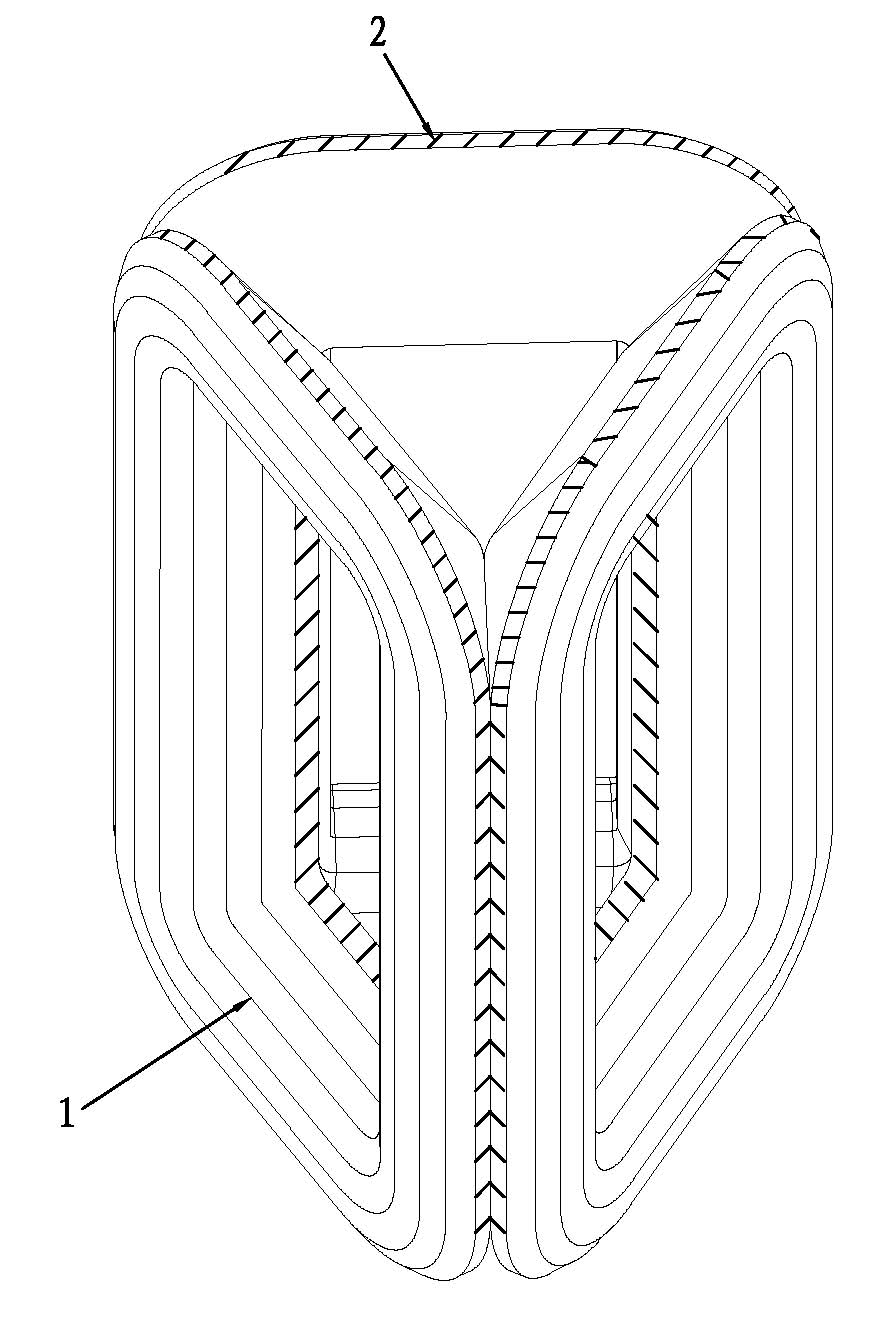

[0014] Such as figure 1 , figure 2 , image 3 As shown, a noise-reducing amorphous alloy three-dimensional wound iron core is composed of three single-frame iron cores 1, and each single-frame iron core 1 is rolled into a certain thickness by multi-layer amorphous alloy strips, according to the thickness It is divided into several levels; a skeleton 2 is arranged on the single-frame iron core 1 .

[0015] Such as figure 2 As shown, when rolling a single-frame iron core, set the frame 2 at the first stage and the last stage; or set the frame 2 at the first stage, or set the frame 2 at the last stage

[0016] It is also possible to set a skeleton between certain adjacent levels in the single frame.

[0017] The material of the frame 2 can be magnetically permeable or non-magnetically permeable.

[0018] The stress of the single-frame iron core 1 is supported by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com