Board to board connector and manufacturing method thereof

A technology of board-to-board connector and manufacturing method, which is applied in the direction of connection, fixed connection, circuit/collector parts, etc., can solve the problems of height change, pin row deformation, etc., and achieve the effect of overcoming pin row deformation and height change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

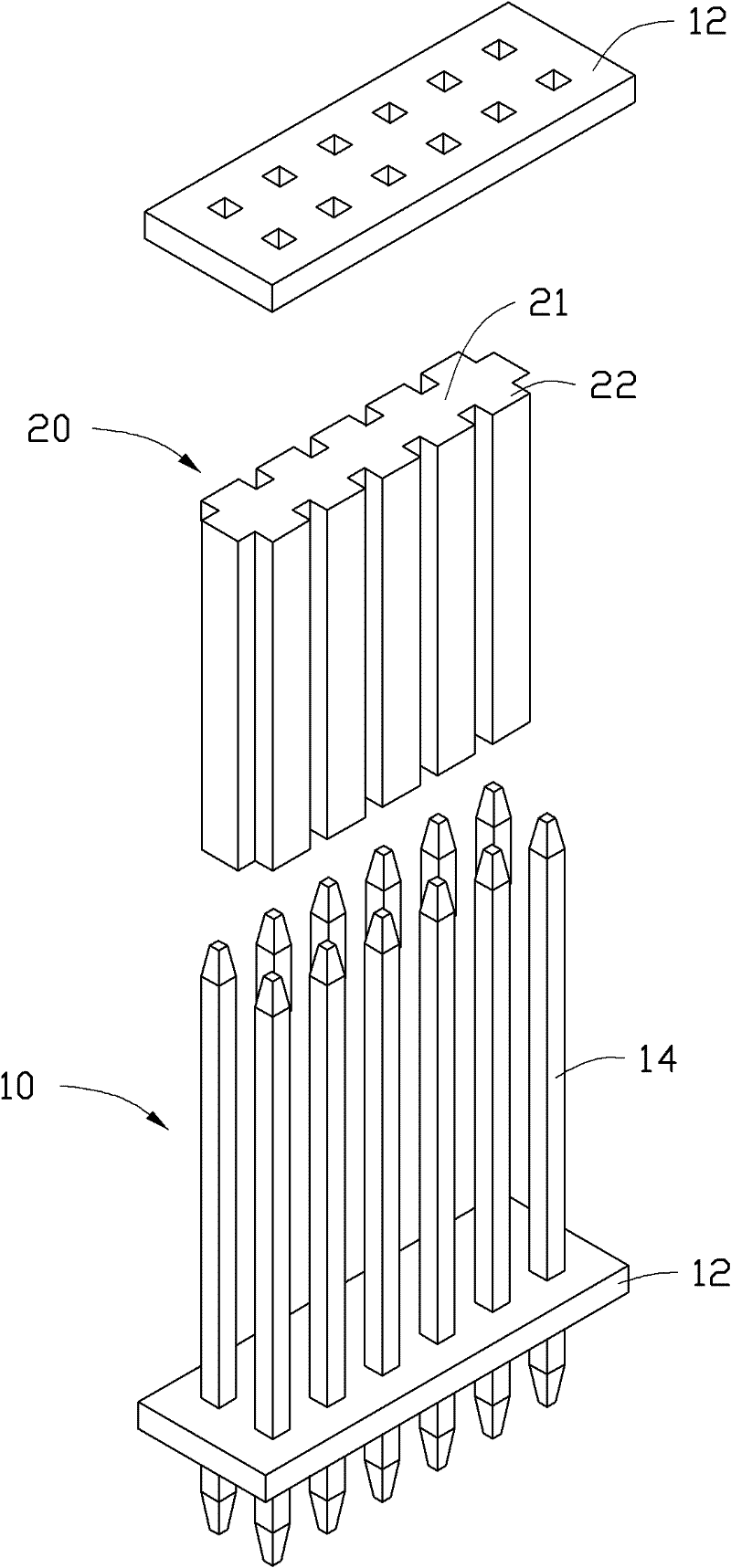

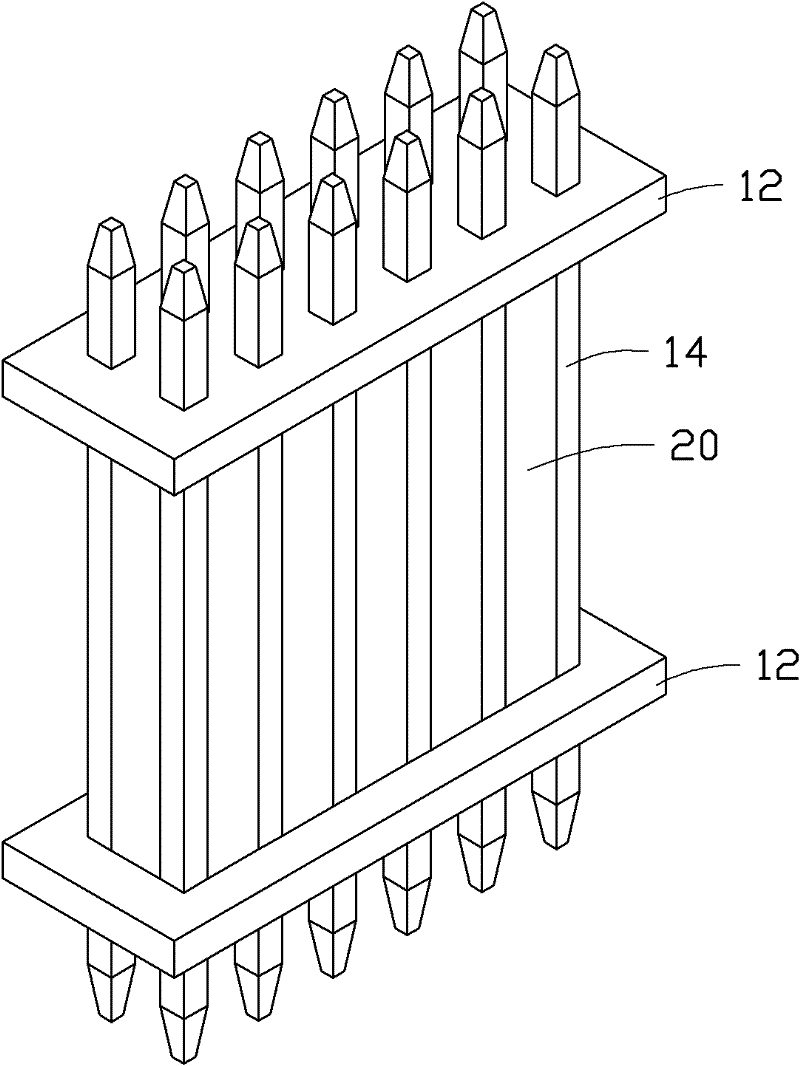

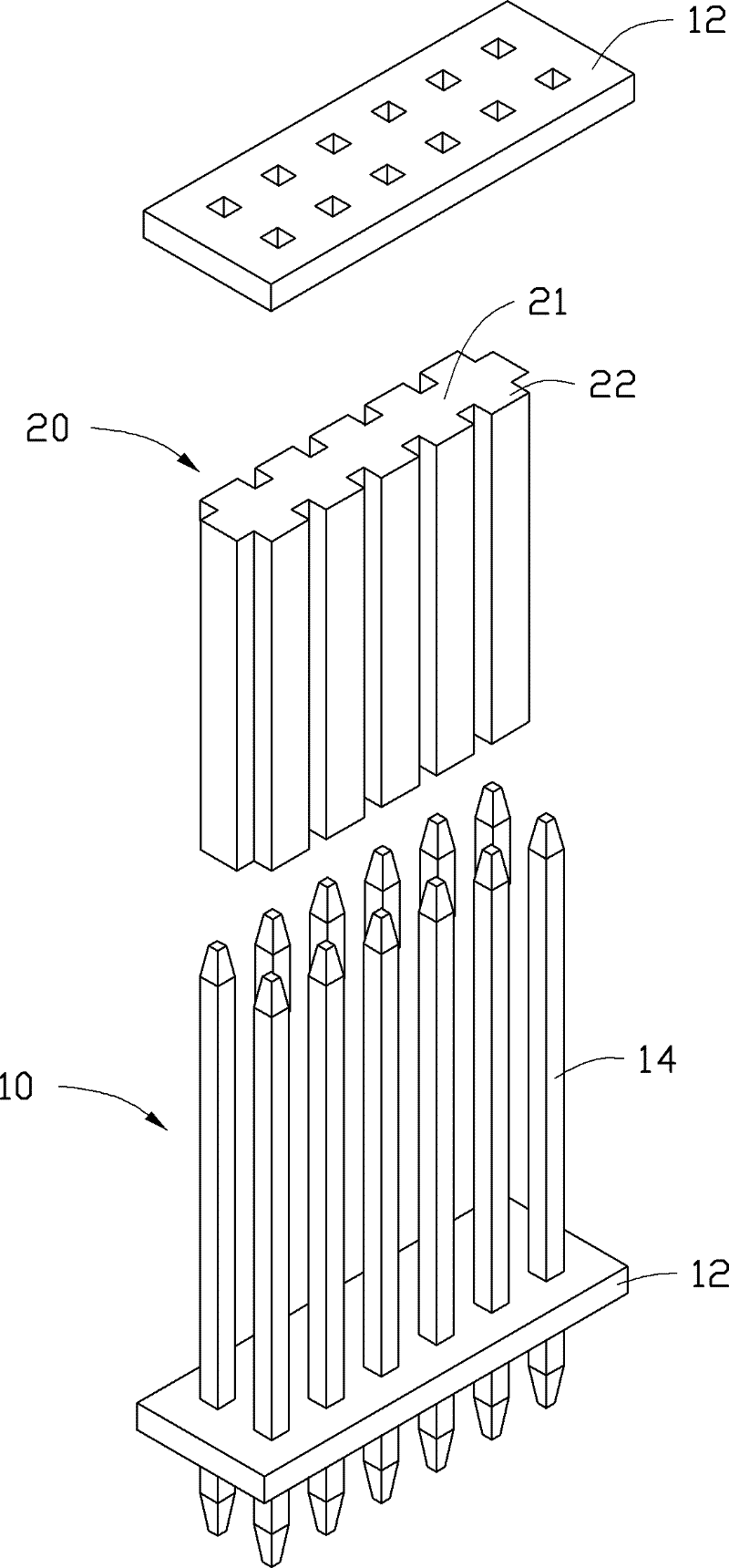

[0011] Please also refer to figure 1 and figure 2 , a preferred embodiment of the board-to-board connector of the present invention includes a double plastic pin header 10 and a support plate 20, the double plastic pin header 10 is the same as the known board-to-board connector, which includes two plastic The body 12 and the double-row needle row 14, the needle row 14 is a straight needle row, and the double-row needle row 14 is arranged in double rows and a plurality of columns to pass through the plastic body 12.

[0012] The support plate 20 is located in the gap formed by the double rows of pins 14 and the two plastic bodies 12 , the support plate 20 includes a plate body 21 and a plurality of protrusions 22 located on two opposite surfaces of the plate body 21 , in this embodiment, the plate body 21 and the plurality of protrusions 22 are integrally formed. The plate body 21 is located in the row-to-row interval of the pin header 14, and the top and bottom ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com