Metal plate face frame of television

A technology of TV and face frame, which is applied in the field of sheet metal face frame, can solve the problems of wasting manpower and material resources, high production cost, complicated operation process, etc., and achieve the effect of saving cost and reducing the number of projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

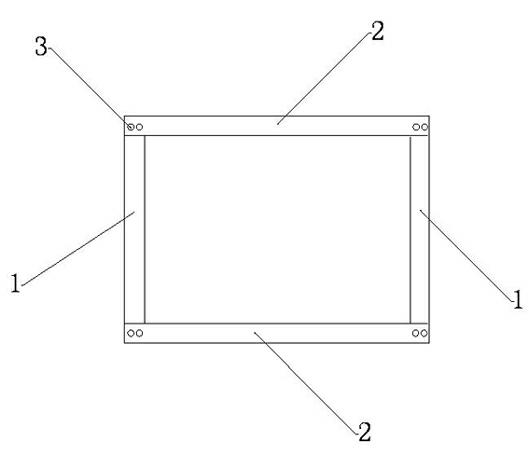

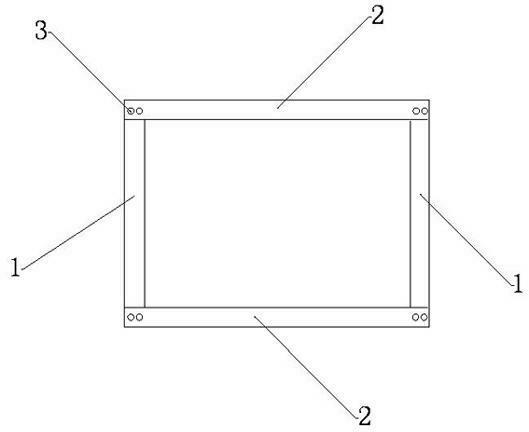

[0010] In order to further reveal the technical solution of the present invention, the implementation mode of the present invention is now described in detail in conjunction with the accompanying drawings: as figure 1 As shown, a TV sheet metal face frame includes a face frame body, the face frame body is connected into a square shape by metal strip sides, and can be composed of two vertical metal strip sides 1 and two horizontal metal strip sides 2, or can be It is composed of two "L"-shaped metal strip sides, and the adjacent two metal strip sides are connected by splicing, which is convenient for installation and disassembly. The edge of the metal strip is formed by stamping with a stamping die, which saves time and effort, and can be mass-produced.

[0011] The connection method of the two adjacent metal strips is inorganic riveting. If the two adjacent metal strips are pasted together, they are riveted together with riveting tools at the riveting position. No auxiliary ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com