Mask with nasal cushion

A mask and lace technology, applied in breathing filters, clothing, life-saving equipment, etc., can solve the problems of blurred glasses, high price, and inability to obtain resilience to ensure tightness, and achieve the effect of improving tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

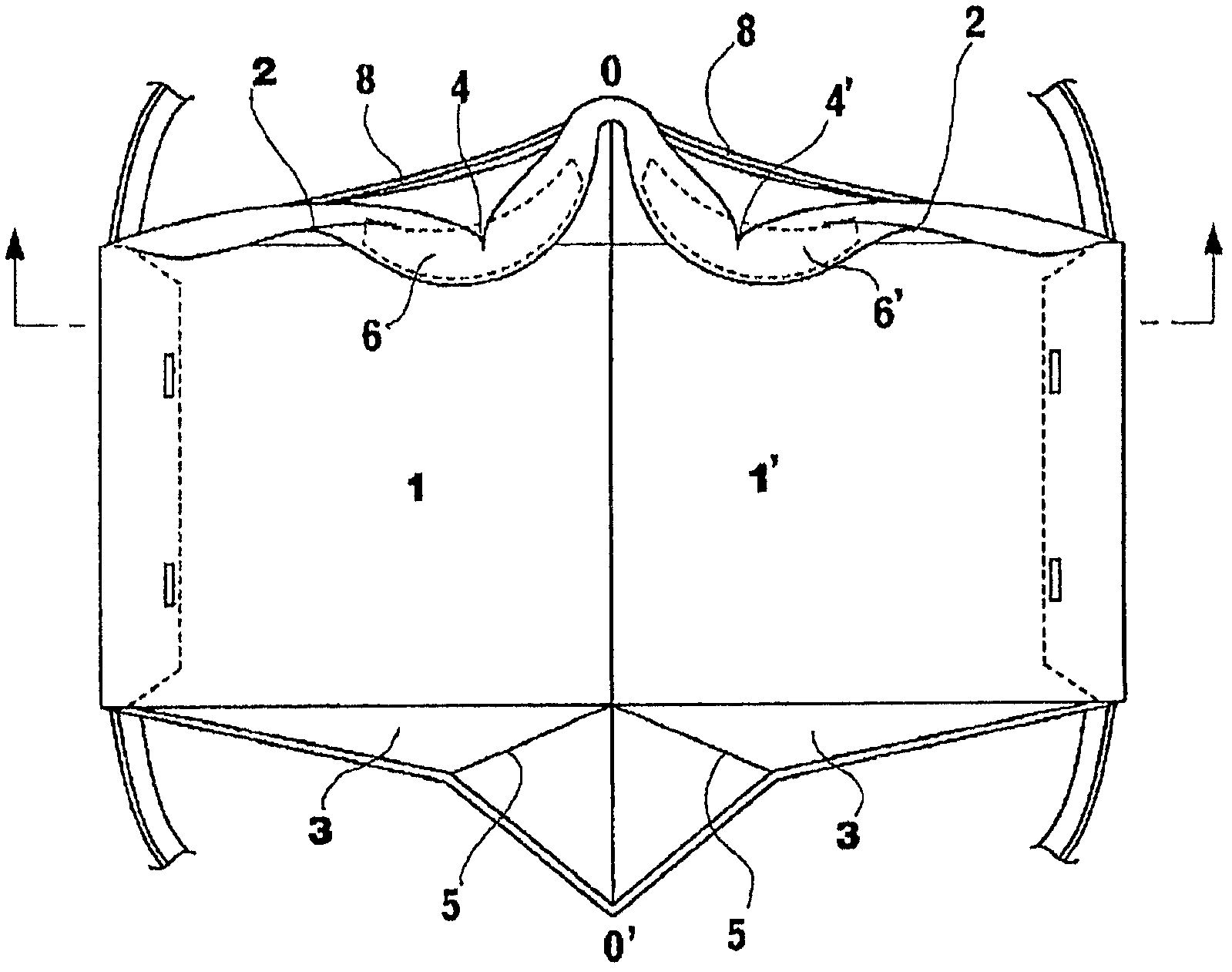

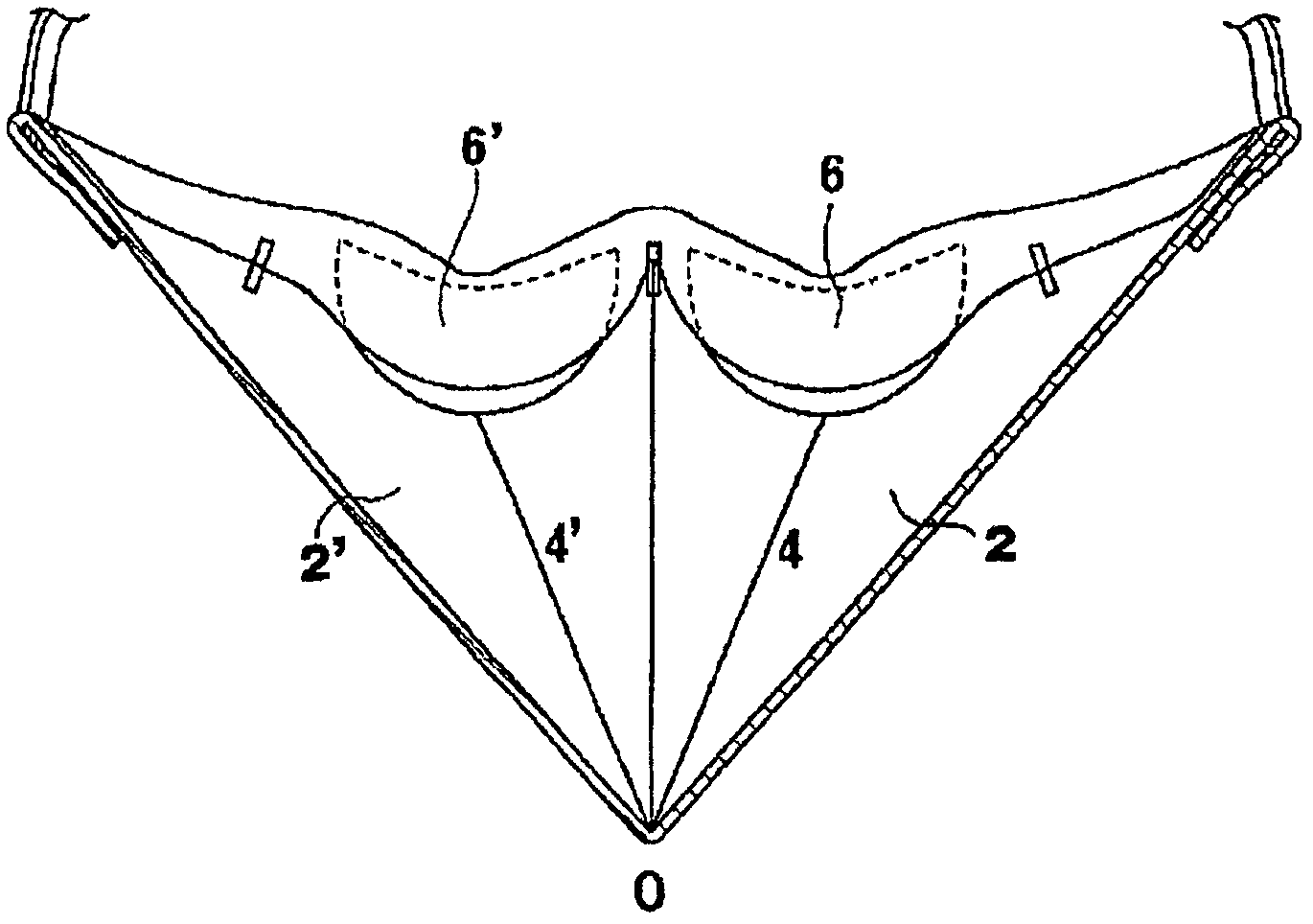

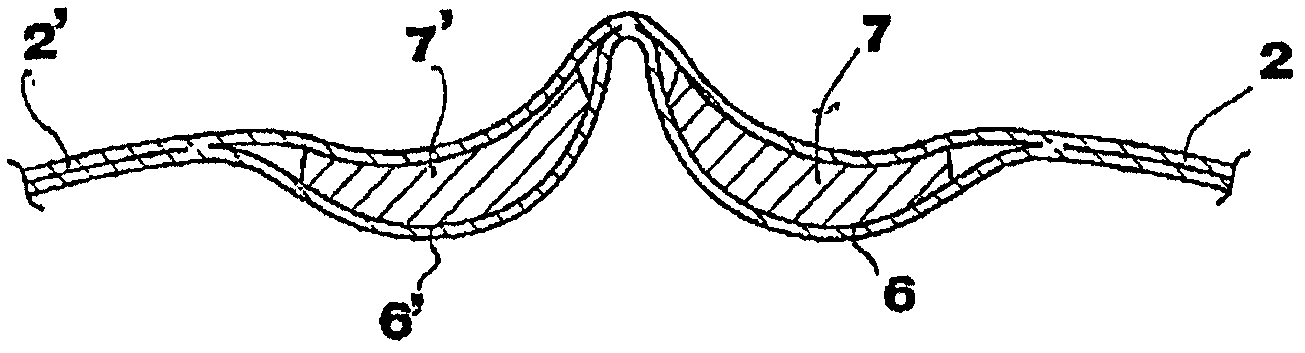

[0026] Fig. is the rear face view of the mouth mask that the present invention relates to, and this mouth mask has rectangular filter 1,1' in central part symmetrically with respect to center line O, O, and triangular filter 2 is integrally set at the top of this rectangle , 2', a triangular filter 3, 3' is integrally arranged at the bottom to form a mask body. The two side edges of the mask body are folded back with tie straps. In addition, in this mask, beams 4, 4' consolidated by ultrasonic welding or the like are provided on the upper triangular filter in a manner that maintains a three-dimensional shape and are easy to fold, and beams 4, 4' consolidated by ultrasonic welding or the like are provided on the lower triangular filter in the same manner. 5, 5'. And, in the present invention, the vicinity of the nose of such a mask is folded back to the side close to the face to set the flaps 6, 6', and the sponge body 7, 7' is inserted into the folded flaps 6, 6'. inside. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com