Solid-liquid separation device

A technology of solid-liquid separation and separation mechanism, which is applied in the direction of separation methods, precipitation separation, chemical instruments and methods, etc., can solve the problems of high labor intensity and low efficiency, and achieve the goals of reducing labor intensity, high degree of automation, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

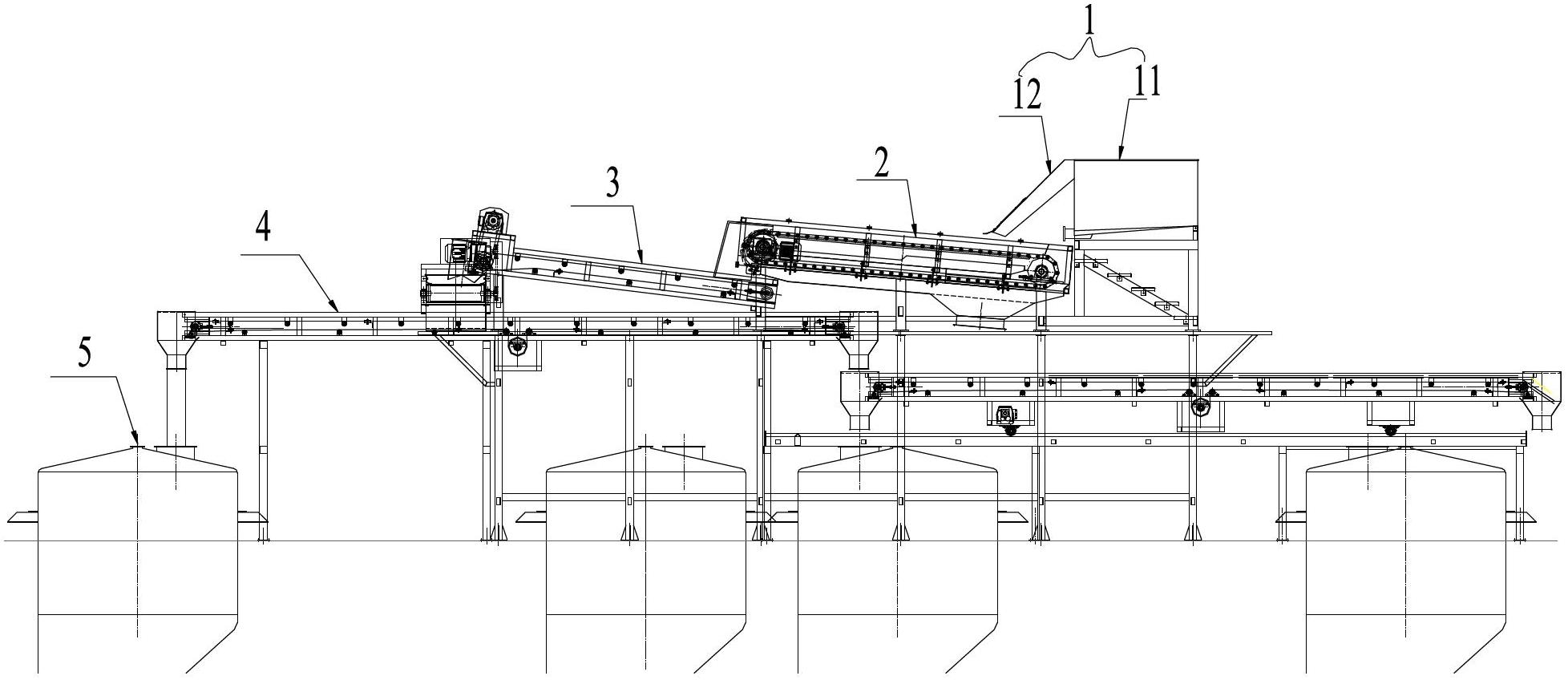

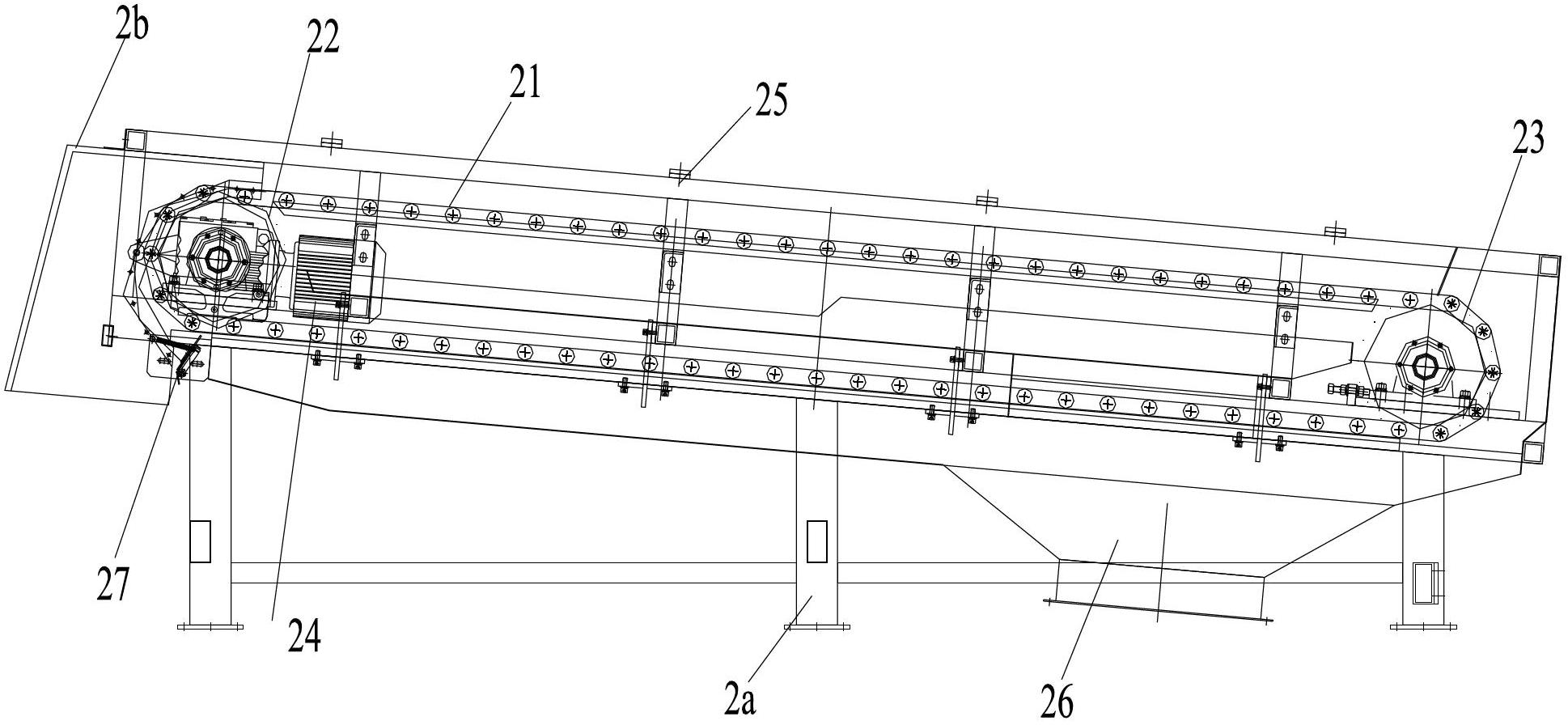

[0024] see Figure 1 to Figure 4 , The solid-liquid separation device in this embodiment includes a layering mechanism 1, a separation mechanism 2, a moisture detection and feedback mechanism 3, a conveying and feeding mechanism 4, and a speed regulating and quantitative mechanism 5.

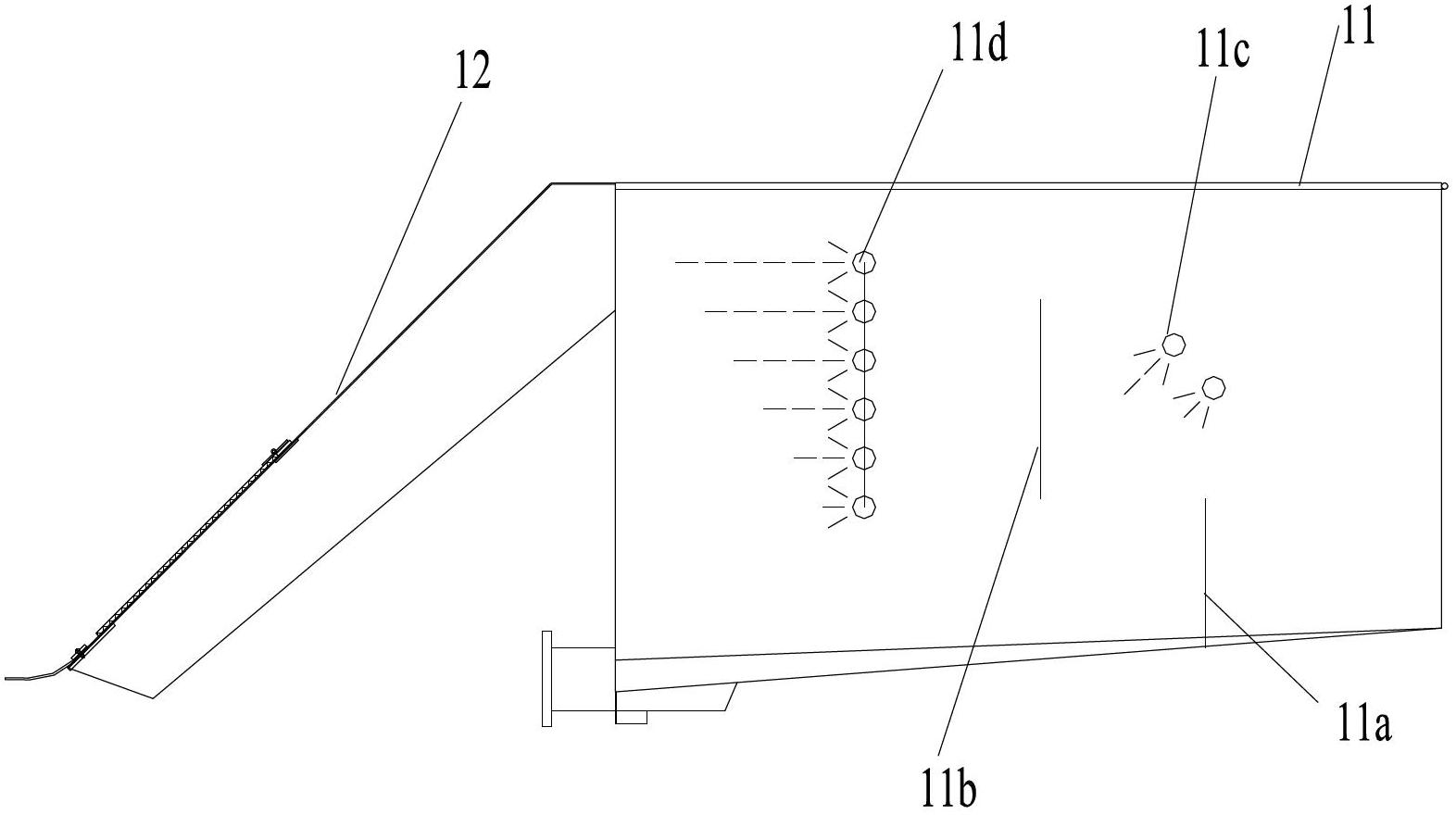

[0025] Wherein, the layering mechanism 1 includes a feeding box 11 and a diversion tank 12, and the feeding box 11 is provided with a first baffle plate 11a, a second baffle plate 11b, a diversion nozzle 11c, and a plurality of shower heads with regulating valves. 11d, the first baffle 11a is arranged at the material inlet of the feeding box, and its lower end is connected to the bottom of the feeding box, the first baffle is used to bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap