Adhesive dispensing device

A technology of dispensing device and dispensing mechanism, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of difficult guarantee, slow dispensing speed, low efficiency, etc., so as to avoid incomplete dispensing Precise, improve dispensing efficiency, high degree of automation and effect of dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

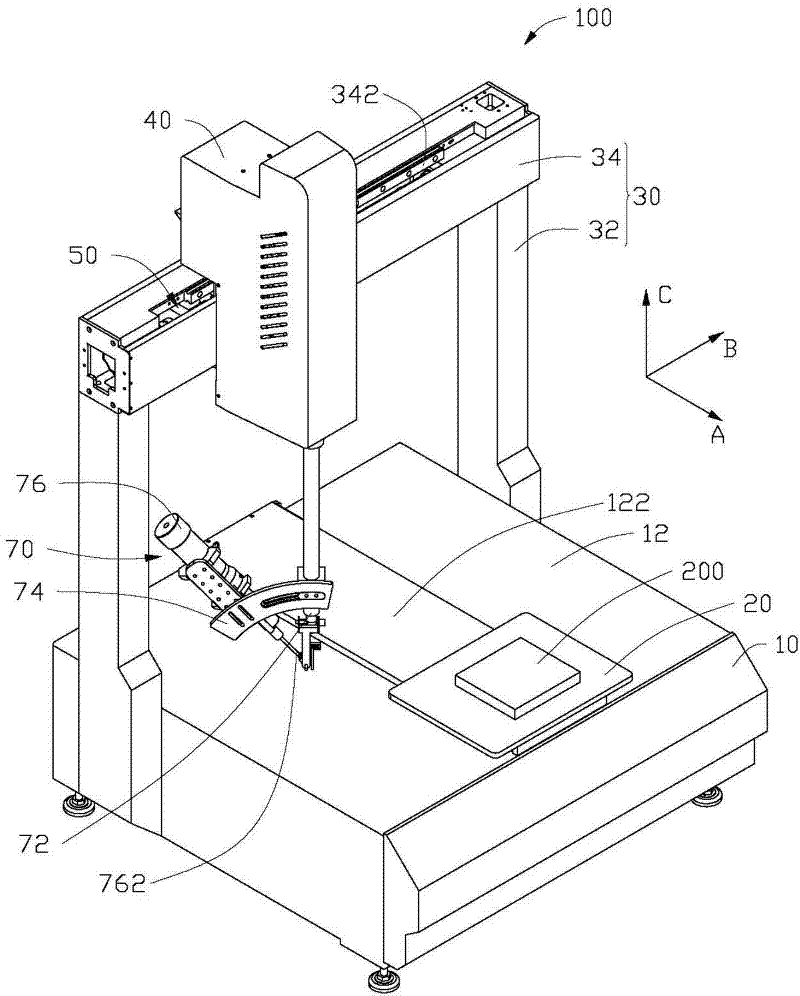

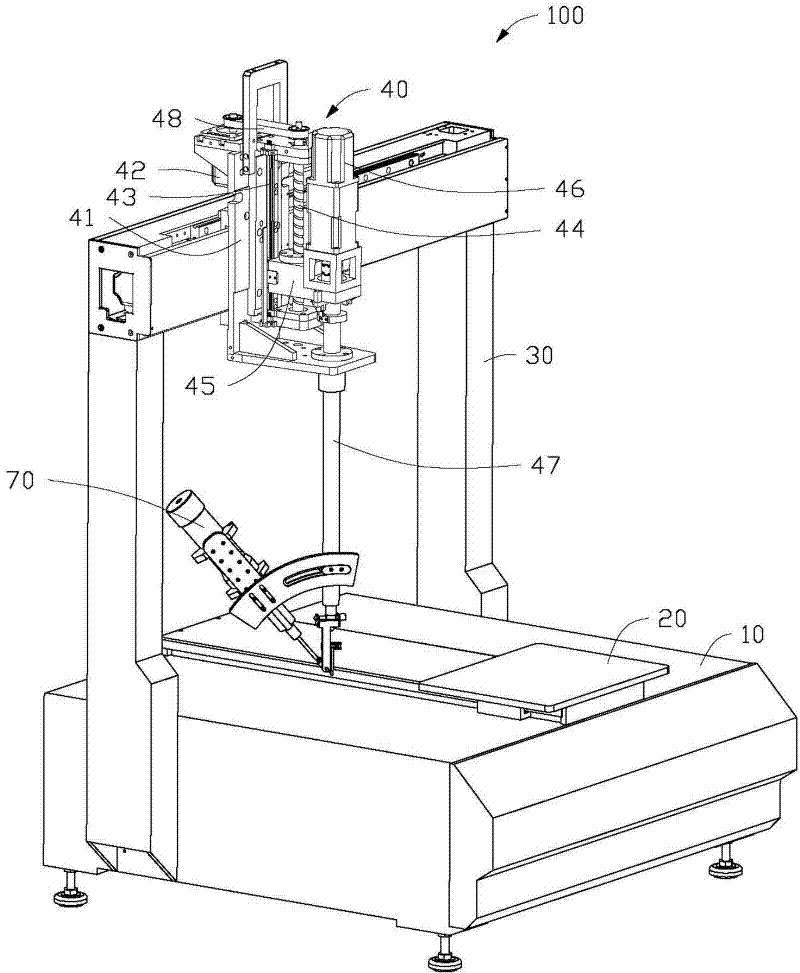

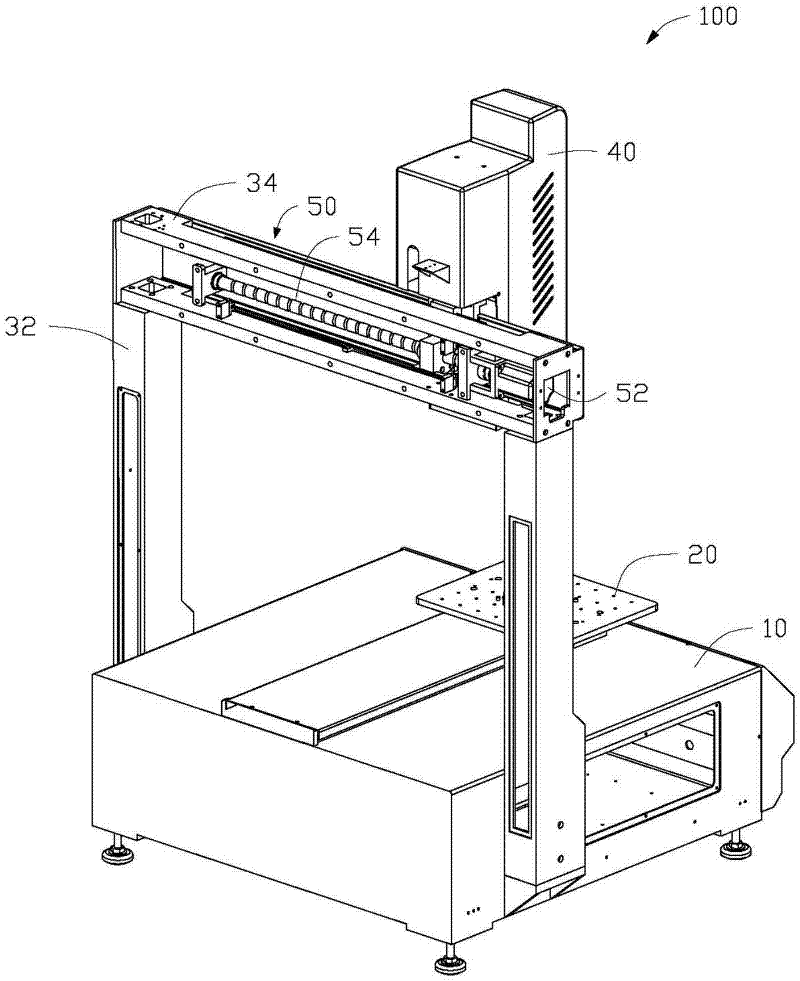

[0013] see figure 1 , the dispensing device 100 includes a control box 10, a workbench 20 mounted on the control box 10, a bracket 30 fixed on the control box 10, a first drive mechanism 40 slidably mounted on the bracket 30 ( ginseng figure 2 ), a second driving mechanism 50 installed on the bracket 30, a third driving mechanism 60 installed in the control box 10 (see image 3 ) and a dispensing mechanism 70 located on the first driving mechanism 40 .

[0014] The control box 10 is used to control the operation of the entire dispensing device 100 . The control box 10 includes a top wall 12 . A first guide rail 122 is parallelly fixed on the top wall 12 along a first direction A, and the workbench 20 is slidably mounted on the first guide rail 122 .

[0015] The bracket 30 includes two uprights 32 fixed on the top wall 12 of the control box 10 and a beam 34 connecting the two uprights 32 . Two second guide rails 342 are parallelly disposed on the beam 34 along a second d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com