Pipe fitting processing forming machine and processing method thereof

A technology for processing forming and pipe fittings, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as poor work efficiency, overall material density, poor structural strength, and inability to directly process pipe material into finished pipe products. , to achieve the effect of improving work efficiency and improving material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0066] Before going into details, it should be noted that relative positional terms used throughout the specification, such as "left", "right", "top", and "bottom", are based on the normal use orientation, that is, the orientation shown in each figure. benchmark.

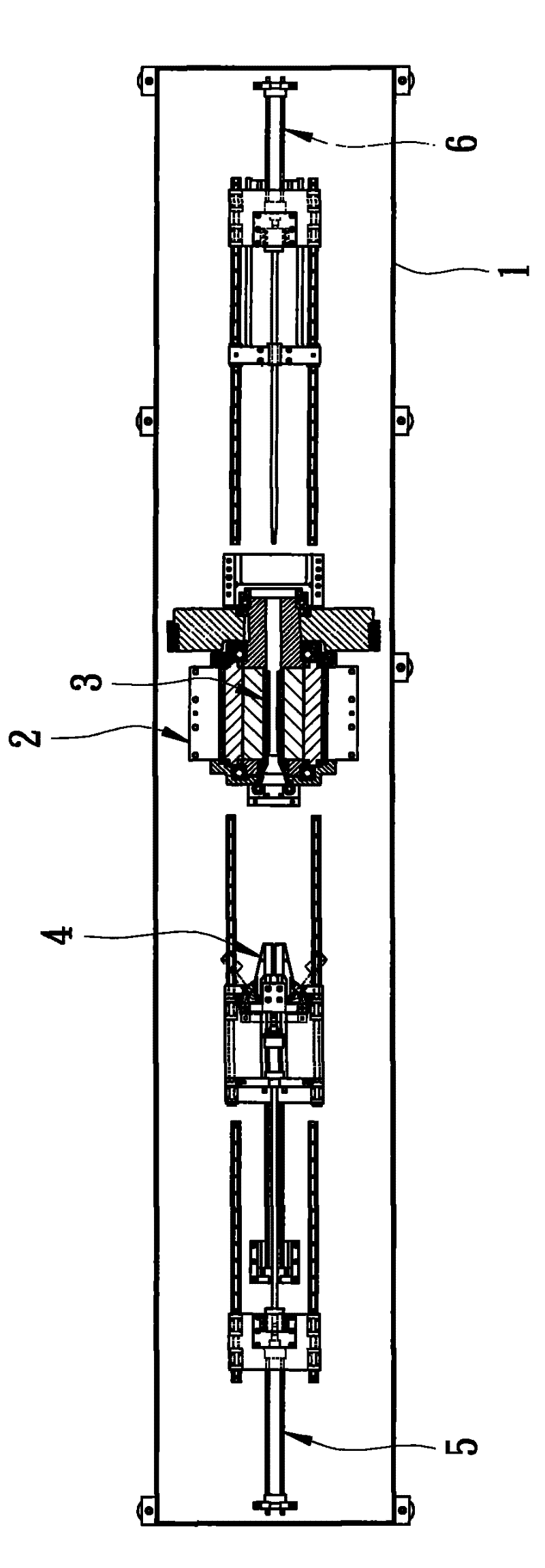

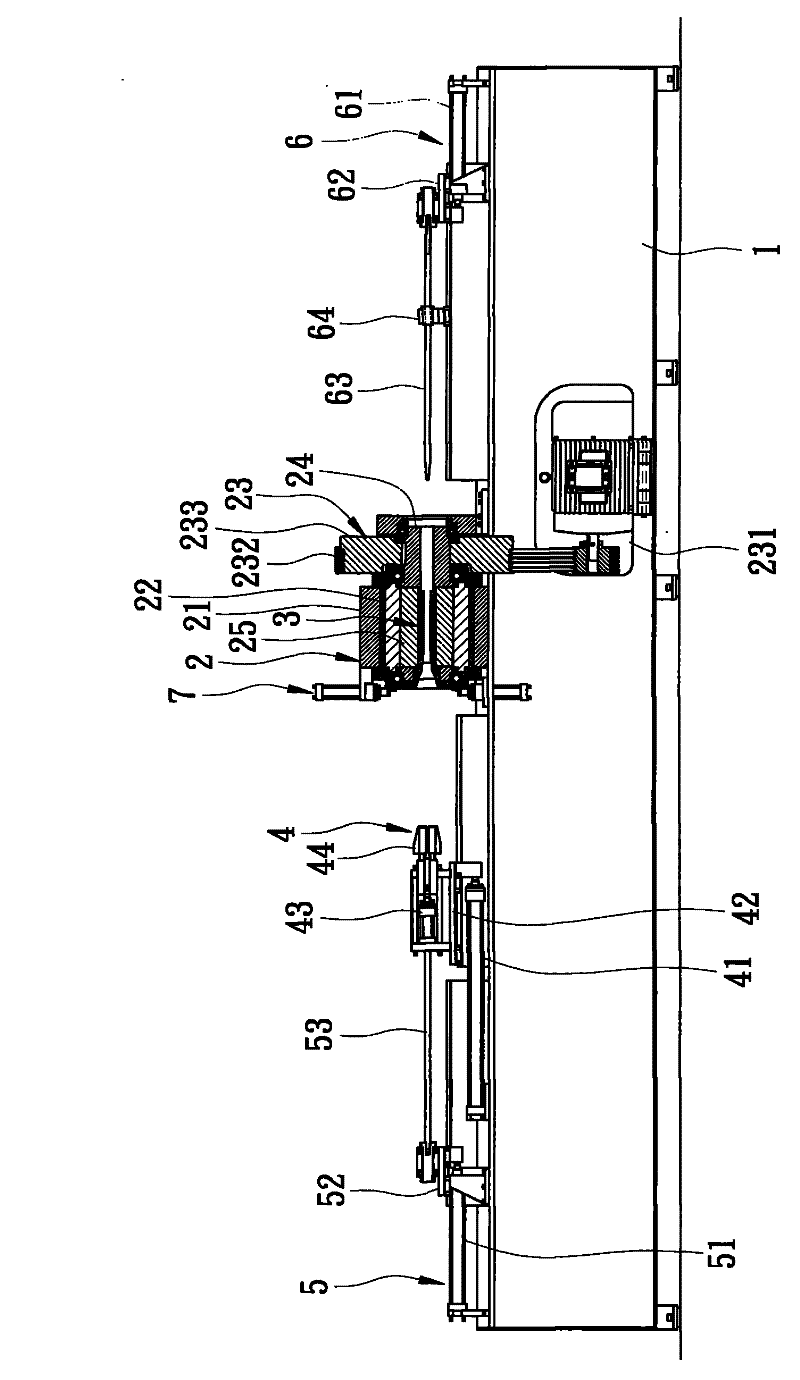

[0067] Such as figure 1 , figure 2 As shown, the preferred embodiment of the pipe fitting processing and forming machine of the present invention includes a machine table 1, a striking device 2, a forming die unit 3, a clamping unit 4, a left feed unit 5, a right feed unit 6 and A material return unit 7 .

[0068] The machine platform 1 is placed along a left-right direction.

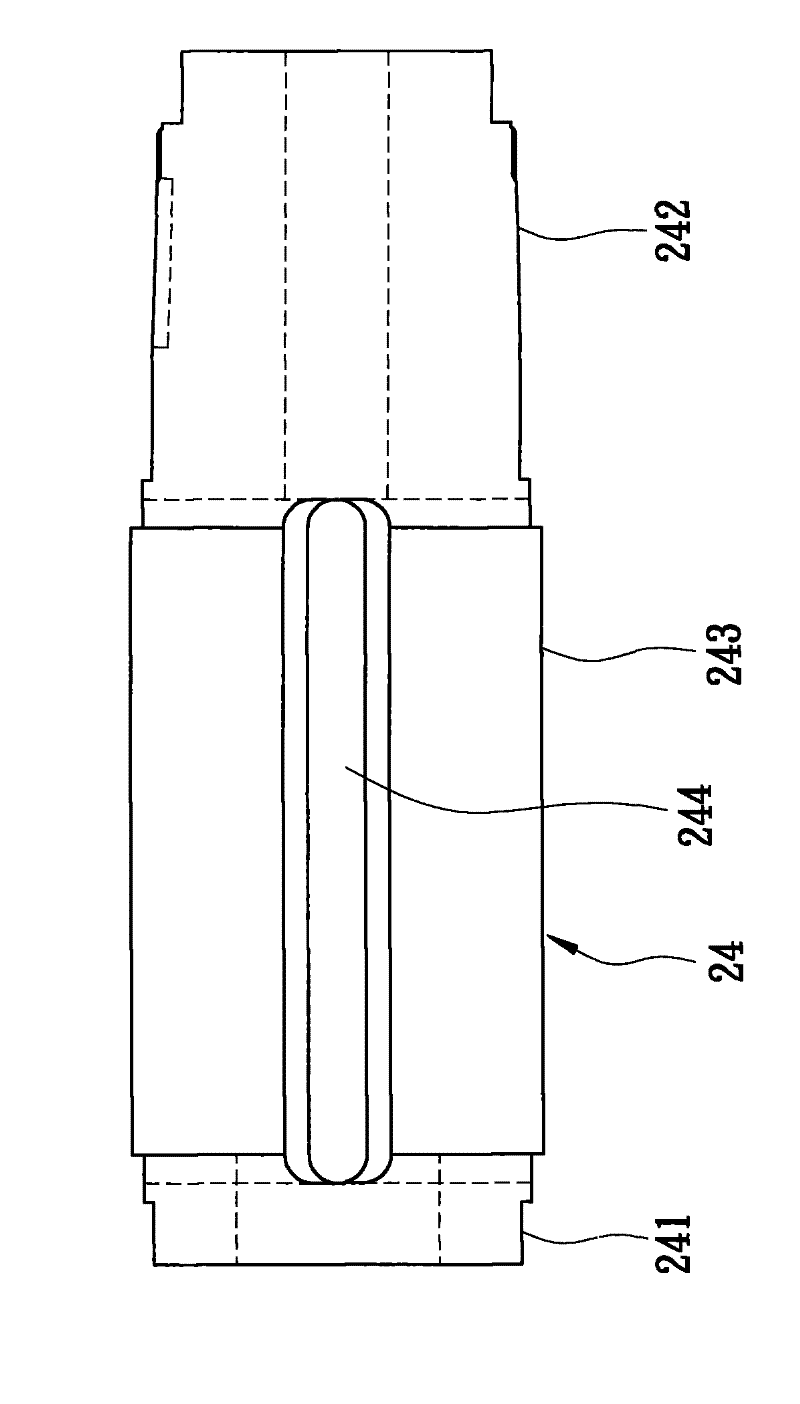

[0069] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 8 As shown, the striking device 2 is installed on the machine platform 1 near the middle position, and includes a fixed unit 21, a roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com