Structure of guide vane vertical surface for improving accuracy of measurement on hydraulic torque of guide vane of model hydraulic turbine

A technology for measuring accuracy and guide vane elevation, applied in hydroelectric power generation, mechanical equipment, machines/engines, etc., can solve problems affecting the measurement accuracy of guide vane water moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

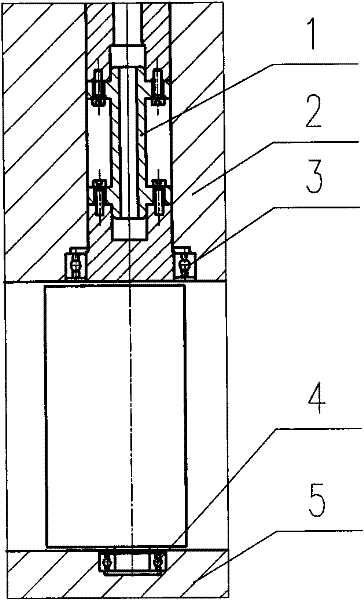

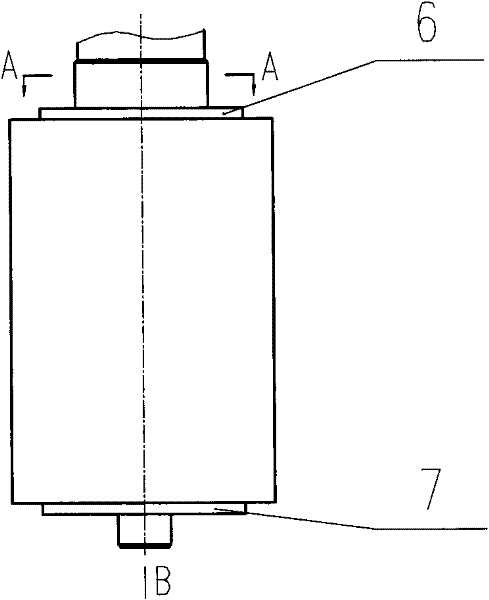

[0009] Such as figure 2 with image 3 As shown, a guide vane elevation structure that improves the measurement accuracy of the guide vane hydraulic moment of a model turbine, such as figure 2 , image 3 with Figure 4 As shown, the upper step 6 protruding from the upper part of the guide vane 1 is mounted on the inner ring of the upper bearing 3, the lower step 7 protruding from the lower part of the guide vane is mounted on the inner ring of the lower bearing 4, and the upper bearing 3 is fixedly mounted on the top In the cover 2, the lower bearing 4 is installed in the bottom ring 5.

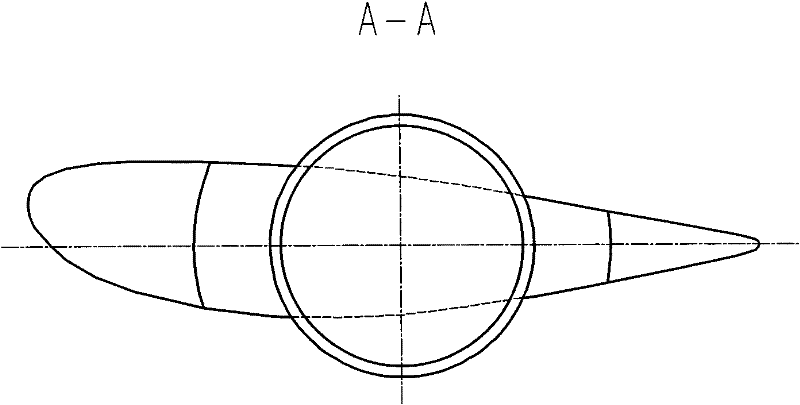

[0010] The working principle of the present invention: Figure 5 As shown, when the guide vane moves upward, the partially protruding upper step 6 on the vertical surface of the guide vane abuts on the inner ring of the upper bearing 3, so that the guide vane cannot continue to move upward in the axial direction, thereby ensuring that the rotating guide vane stands up. There is always no contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com