A screw transmission efficiency testing device

A technology for screw transmission and efficiency testing, applied in measuring devices, force/torque/work measuring instruments, power measurement, etc., can solve the problem of difficult to simulate the friction and wear state of the screw pair, which affects the authenticity of the test data, and the axial load of the screw pair is small and other problems, to achieve the effect of simple structure, ingenious design, and elimination of frictional moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

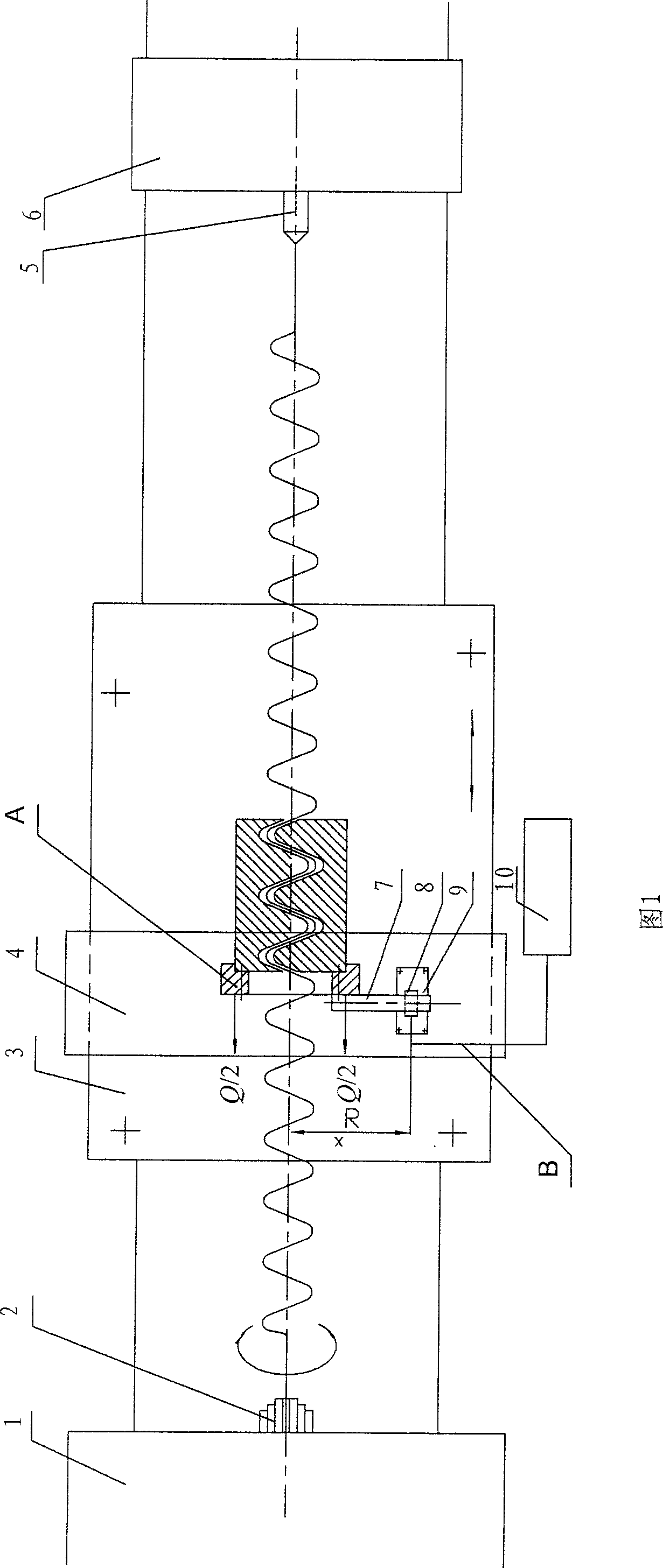

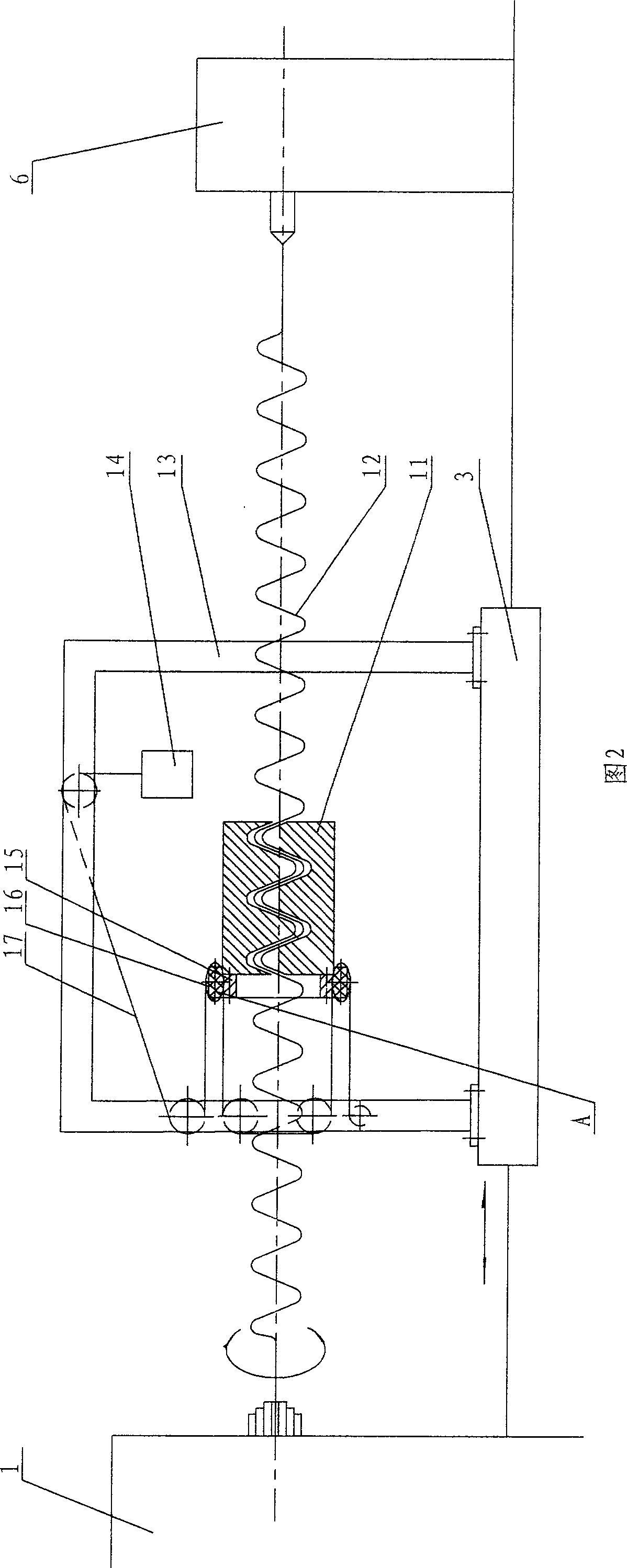

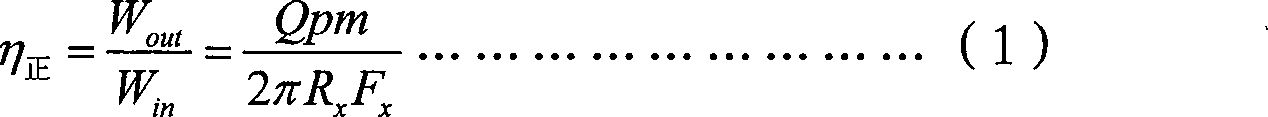

[0010] The principle diagram of the test device of the present invention is shown in Figure 1, comprising a lathe headstock 1, a tool rest carriage containing a large carriage 3 and a middle carriage 4, a lathe tailstock 6 with a tailstock top 5, and a loading device A , test device B, tested nut 11, tested lead screw 12, wherein test device B comprises rigid cantilever bar 7, force sensor 8, sensor seat 9, data acquisition and display system 10, and tested lead screw 12 one ends are clamped on In the chuck 2 of the headstock 1 of the lathe, the top 5 of the tailstock on the tailstock 6 of the lathe is pushed against the center hole at the other end of the screw 12 to be tested, and the nut 11 to be tested and the screw 12 to be tested form a screw transmission pair, and the rigidity One end of the cantilever rod 7 is fixedly connected to the loading device A, and the other end of the rigid cantilever rod 7 is connected to the force sensor 8 floating to prevent the nut under te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com