Rotary table of a photolithography machine

A technology of rotary table and lithography machine, which is used in microlithography exposure equipment, workbench, photolithography process exposure device, etc. The effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be described in detail below.

[0027] The rotary table of the lithography machine described in the present invention can be realized in a variety of alternative ways. The following is a description of a preferred embodiment. Of course, the present invention is not limited to this specific embodiment. The well-known general replacements are undoubtedly covered by the protection scope of the present invention.

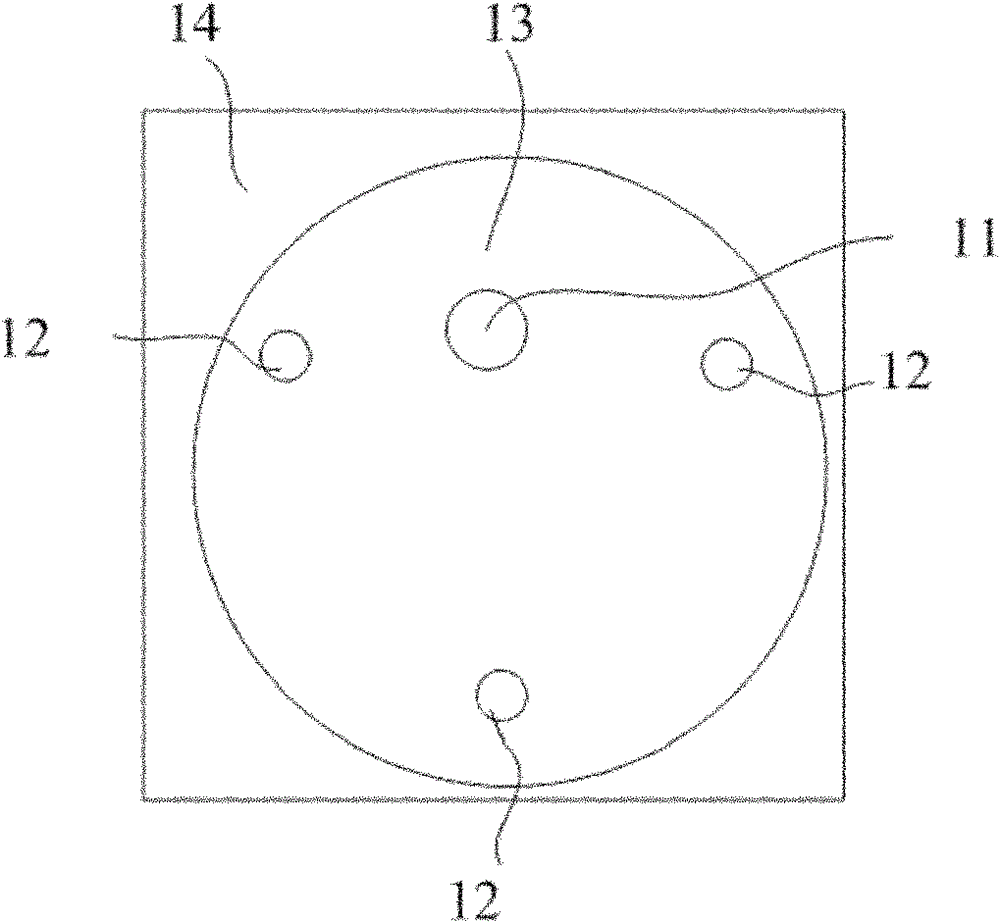

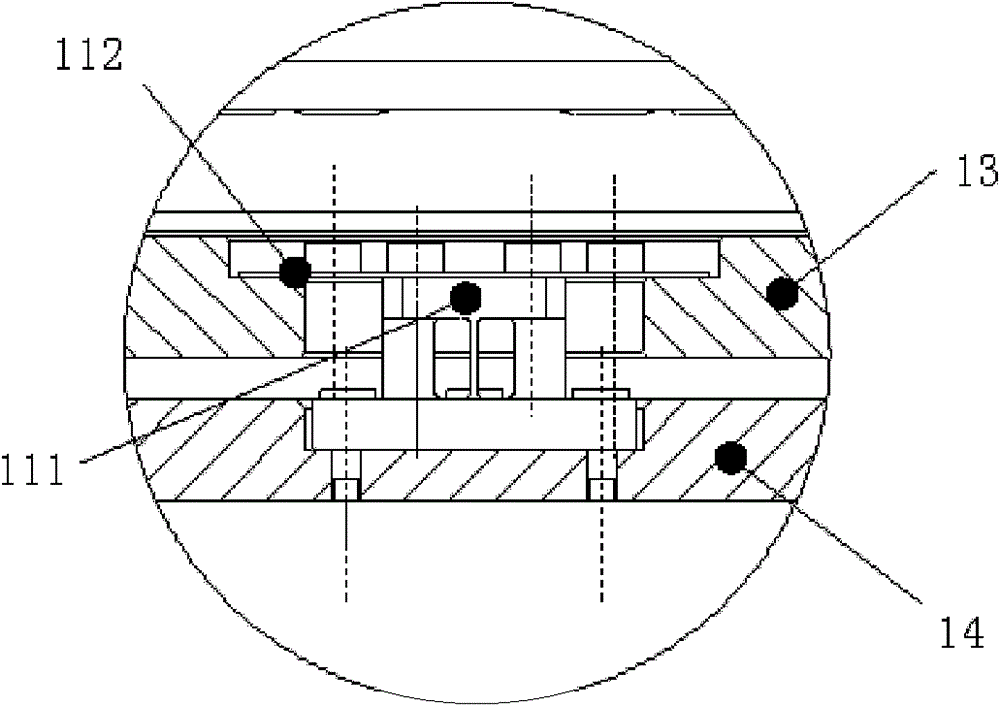

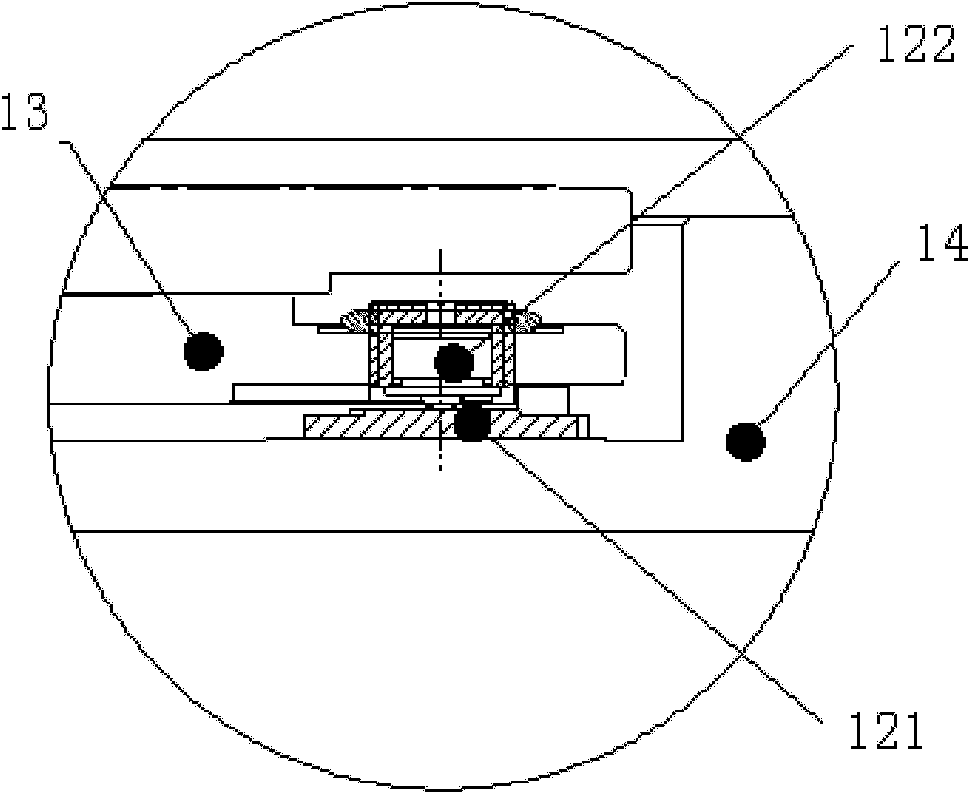

[0028] Please see Figure 4 , Figure 4 It is a schematic diagram of the top view structure of the rotary table of the lithography machine of the present invention, such as Figure 4 As shown, the lithography machine rotary table of the present invention includes: a substrate 24, a work table 23, a supporting mechanism 22, a rotation center positioning mechanism 21 and a driving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com