Mask aligner rotating platform

A technology of a rotary table and a lithography machine, which is used in microlithography exposure equipment, workbenches, photolithography process exposure devices, etc. Reduce the effect of contact point deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below.

[0027] The rotary table of the photolithography machine described in the present invention can be realized in various alternative ways. The following is an illustration through a preferred embodiment. Of course, the present invention is not limited to this specific embodiment. Known general substitutions are undoubtedly covered by the protection scope of the present invention.

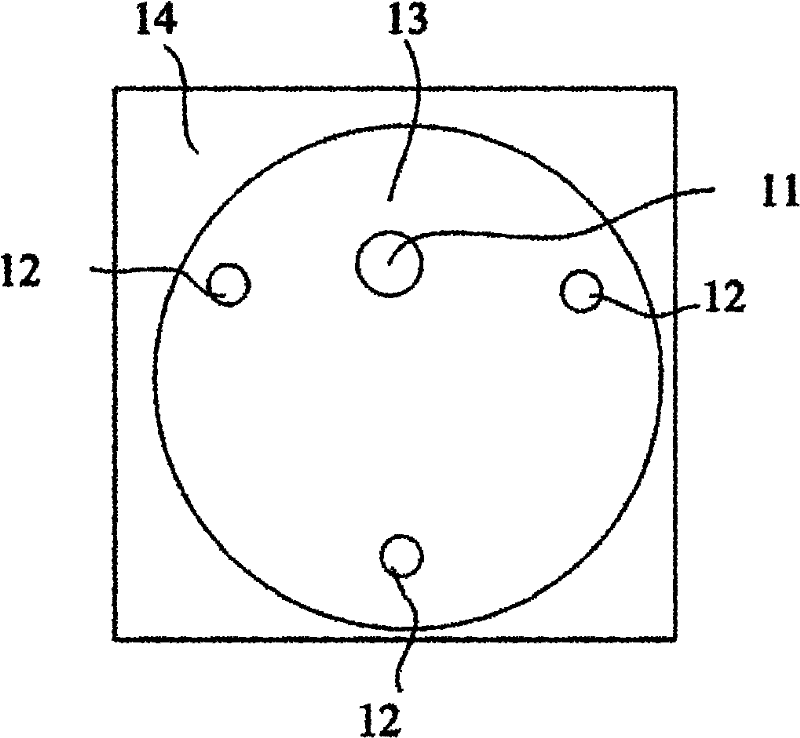

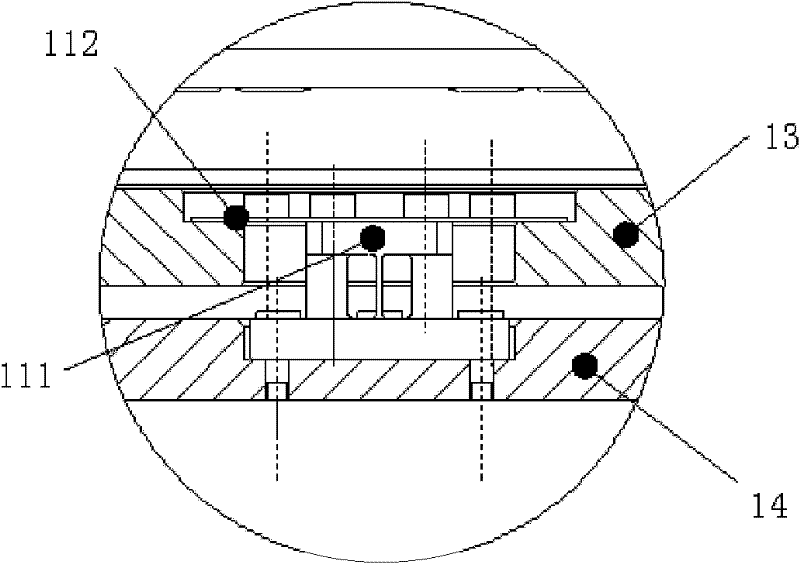

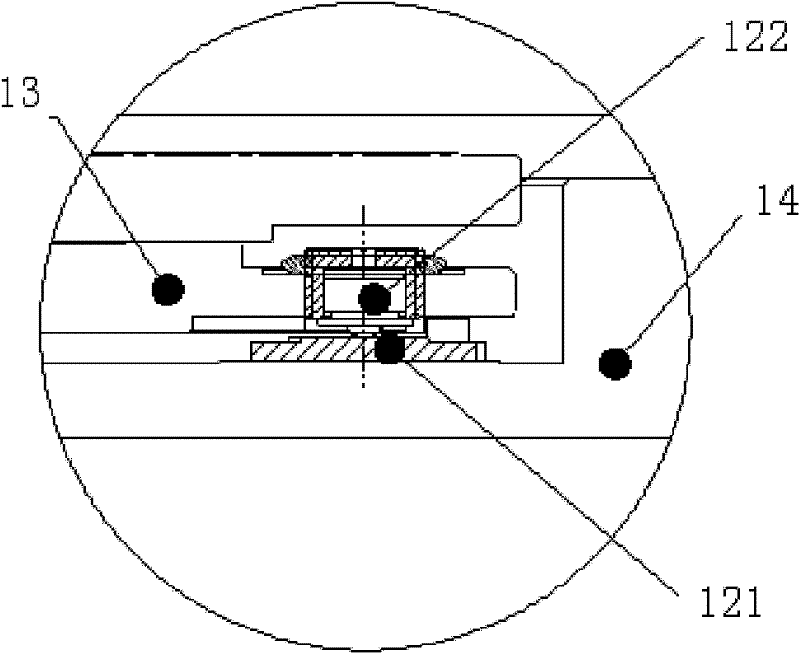

[0028] Please see Figure 4 , Figure 4 It is a schematic diagram of the top view structure of the rotary table of the photolithography machine of the present invention, such as Figure 4 As shown, the rotary table of the lithography machine of the present invention includes: a substrate 24, a worktable 23, a support mechanism 22, a rotation center positioning mechanism 21 and a drive mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com