Sliding type elastic belt

A sliding type, belt technology, applied in clothing belts, clothing, clothing, etc., can solve the problems that the belt tightness cannot be adjusted, can not achieve micro-adjustment, and can only be separated by a certain distance, and achieves simple structure, convenient processing, and comfort. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

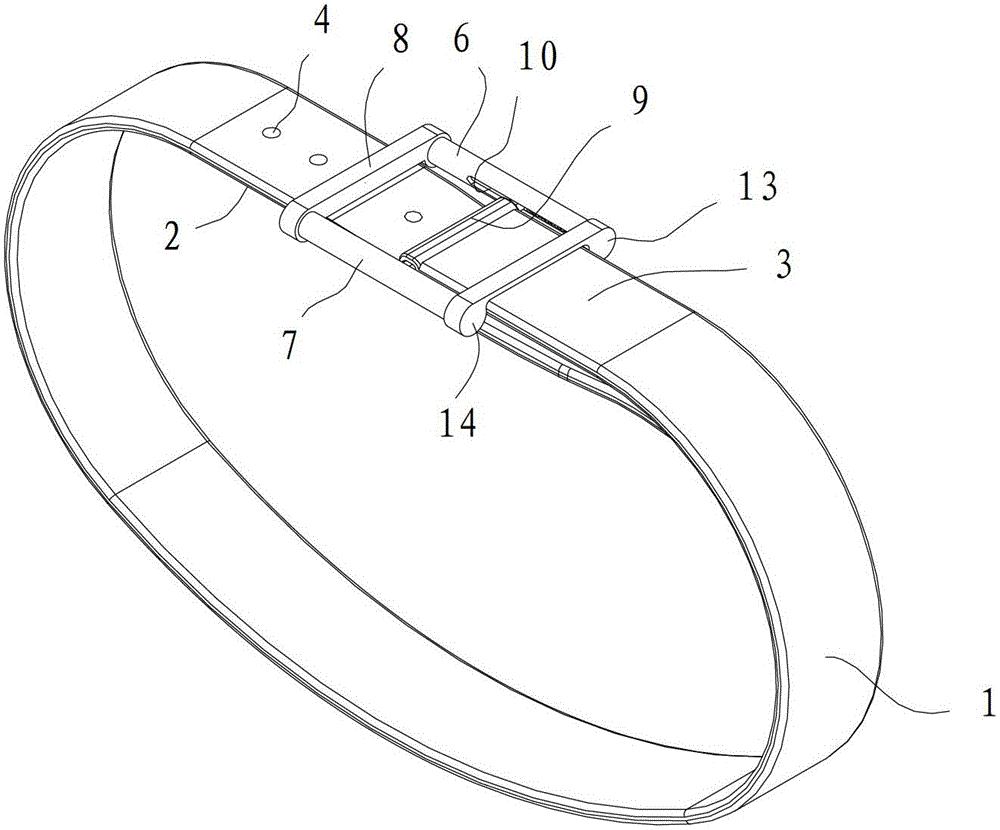

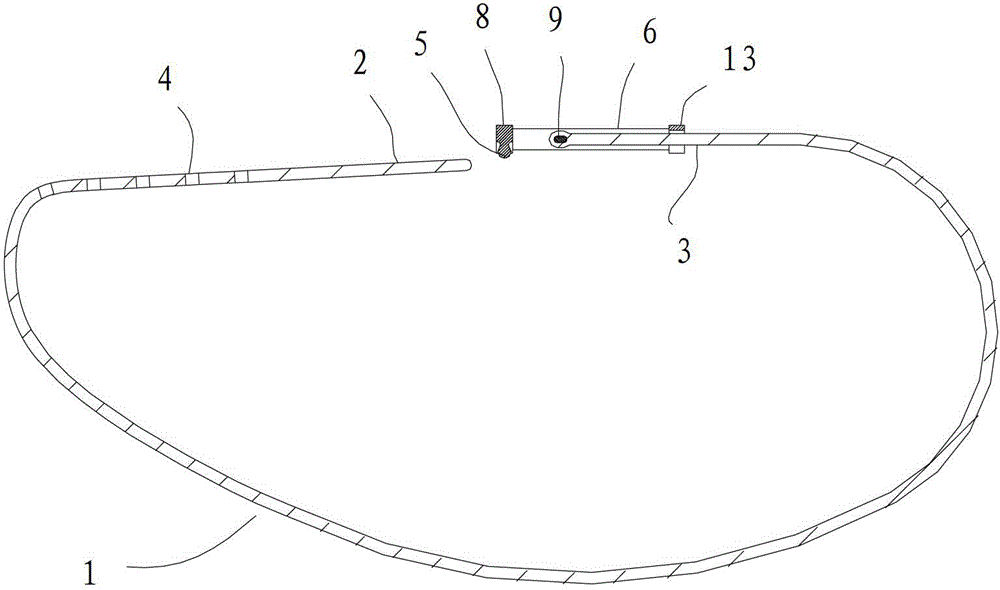

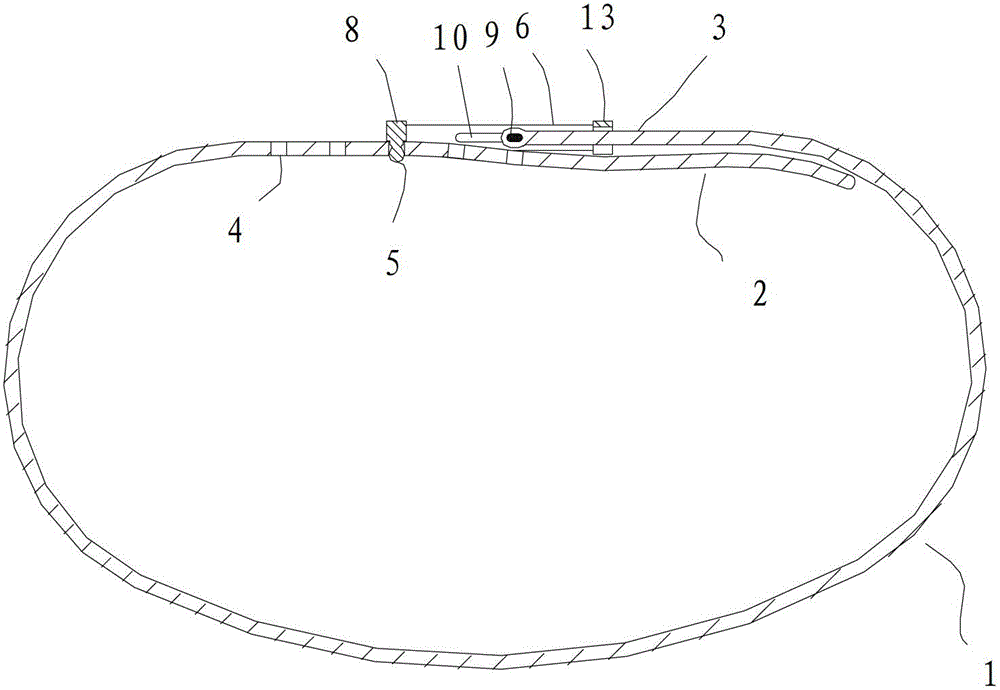

[0028] refer to Figure 1-5 , a sliding elastic belt, which is composed of a belt buckle provided with a hook nail 5 and a belt 1 with a fixed end 3 and a free end 2, and the free end 2 of the belt 1 is provided with several positioning holes for matching with the hook nail 5 4. Two adjacent positioning holes 4 are set at a certain distance. The belt buckle comprises a first bracket 6, a horizontal bracket 8, a second bracket 7 and a sliding bracket 9, wherein the first bracket 6, the horizontal bracket 8 and the second bracket 7 are connected in sequence and form a U shape, and the two ends of the sliding bracket 9 A first plug 13 and a second plug 14 are respectively provided, and sliding grooves 10 are respectively provided on the first bracket 6 and the second bracket 7, and the first plug 13 and the second plug 14 are respectively embedded in the sliding grooves 10 . The sliding slots 10 extend to the ends of the first bracket 6 and the second bracket 7 respectively, an...

Embodiment 2

[0033] refer to Figure 6 , is another kind of sliding elastic belt, the belt buckle includes a first bracket 6, a horizontal bracket 8, a second bracket 7 and a sliding bracket 9, wherein the first bracket 6, the horizontal bracket 8 and the second bracket 7 are connected in sequence and surround U-shaped, the two ends of the sliding bracket 9 are respectively provided with a first plug 13 and a second plug 14, the first bracket 6 and the second bracket 7 are respectively provided with a sliding groove 10, the first plug 13 and the second The plugs 14 are respectively embedded in the slide grooves 10 . The sliding slots 10 extend to the ends of the first bracket 6 and the second bracket 7 respectively, and end covers that can close the sliding slots 10 are respectively provided at the ends of the first bracket 6 and the second bracket 7. In this embodiment , the end cover is composed of a first plug 13 and a second plug 14, and the first plug 13 and the second plug 14 are re...

Embodiment 3

[0035] refer to Figure 7 , is a kind of sliding elastic belt, and the belt buckle includes a first bracket 6, a horizontal bracket 8, a second bracket 7 and a sliding bracket 9, wherein the first bracket 6, the horizontal bracket 8 and the second bracket 7 form a U shape, and the sliding The two ends of bracket 9 are respectively provided with first plug 13 and second plug 14, and first bracket 6 and second bracket 7 are respectively provided with sliding groove 10, and first plug 13 and second plug 14 are embedded respectively in the sliding groove 10. The sliding slots 10 extend to the ends of the first bracket 6 and the second bracket 7 respectively, and end covers that can close the sliding slots 10 are respectively provided at the ends of the first bracket 6 and the second bracket 7. In this embodiment , the end cover is composed of a first plug 13 and a second plug 14, and the first plug 13 and the second plug 14 are respectively connected to the spring 11. The ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com