Heat protection self-alignment fine-tuning paper matrix molding equipment

A molding equipment and heat resistance technology, applied in textiles and papermaking, etc., can solve the problems of inconsistent mold gap, dislocation of upper and lower molds, heat loss, etc., to reduce heat transfer area, uniform mold clamping gap, and improve working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

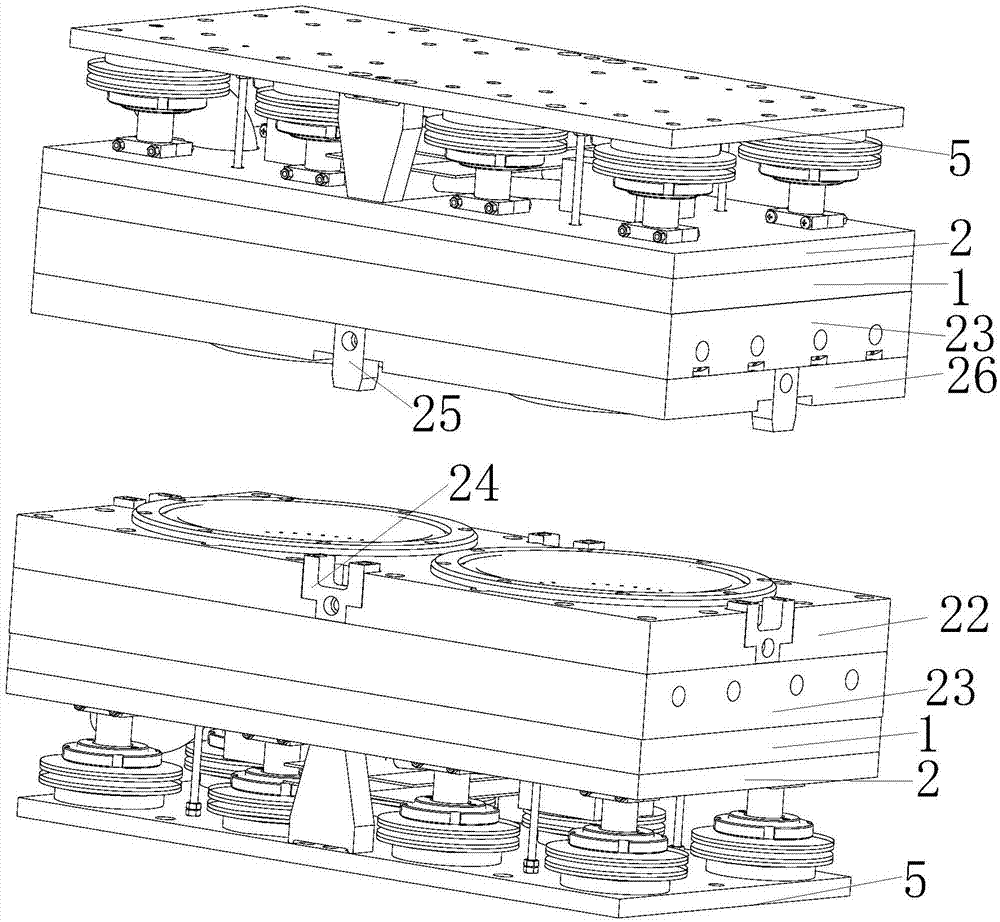

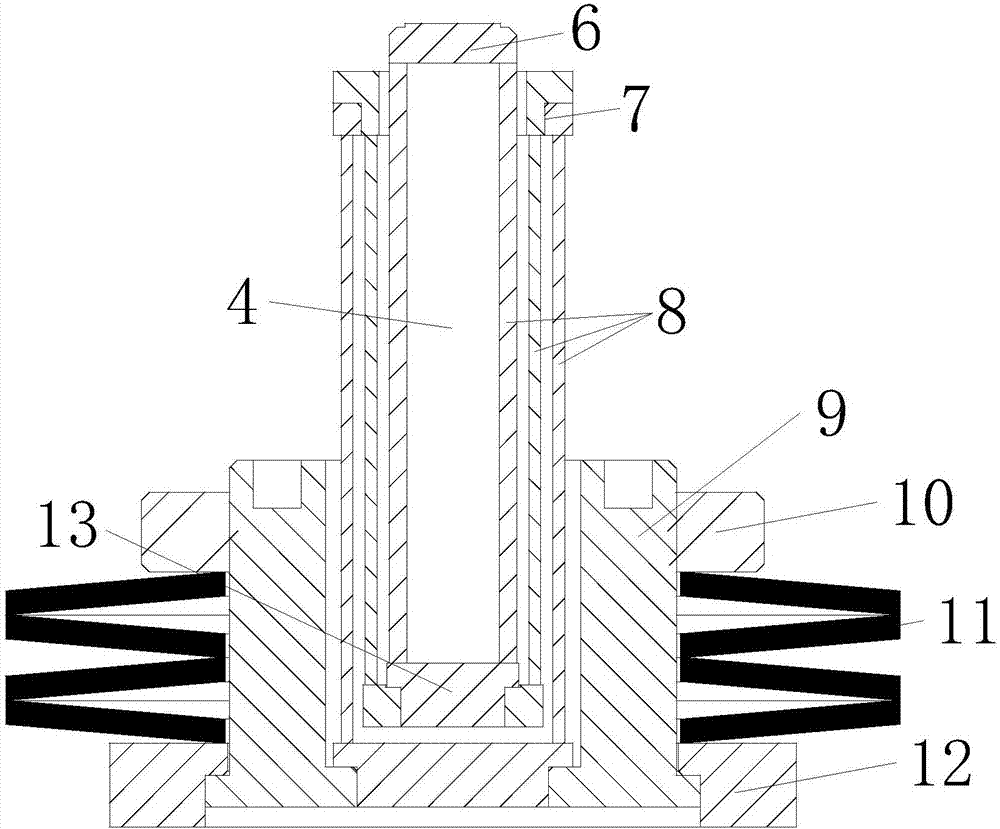

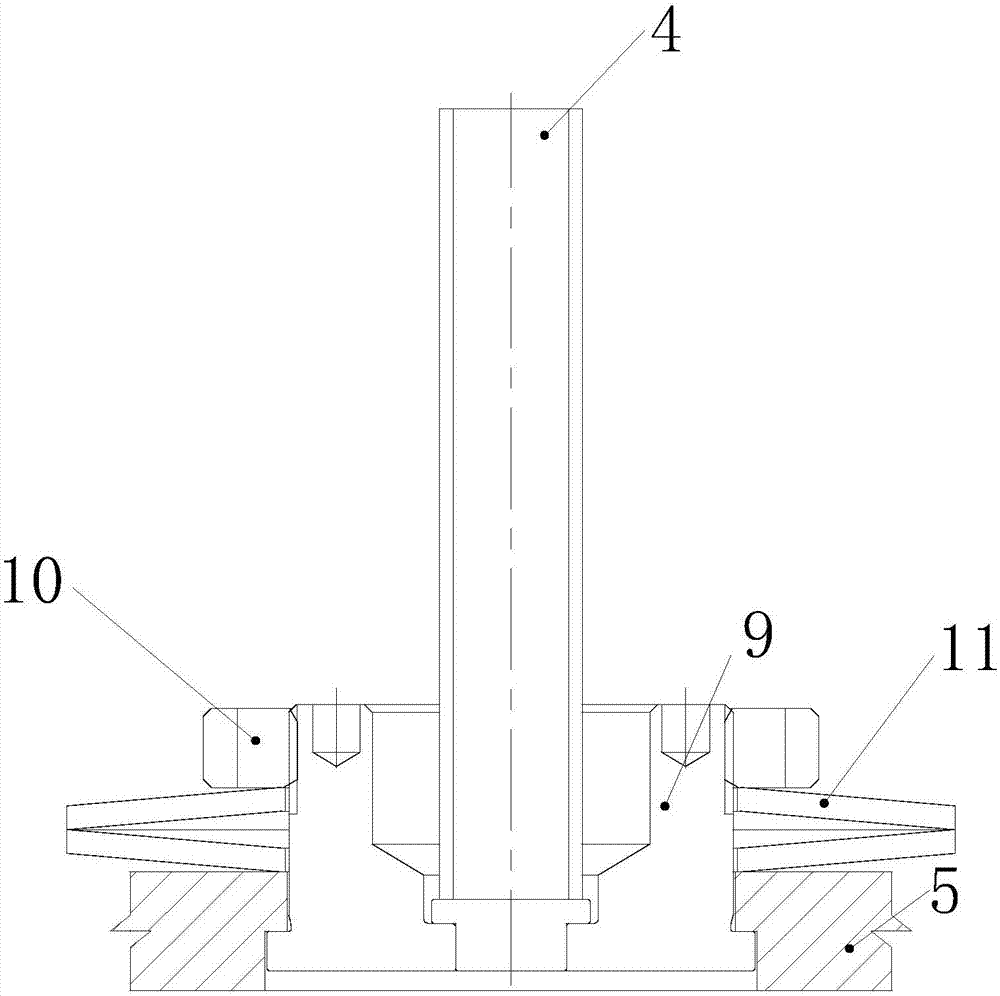

[0035] refer to Figure 1 to Figure 8 . A kind of paper mold forming equipment with self-adjustable thermal resistance, comprising an upper mold 26 and a lower mold 22, the upper mold 26 and the lower mold 22 are respectively connected with a heating plate 23, a heat conducting plate 1 and a bottom plate 5 in sequence, and the heat conducting The plate 1 and the bottom plate 5 are connected to each other through more than two heat-resistant elastic supports 4 and positioning beams. The heat-resistant elastic supports 4 include a heat-resistant column assembly, a mounting base 9 and a flange 12 in sequence from the inside to the outside. The thermal column assembly is placed in the mounting seat 9, the flange 12 is connected to the bottom plate 5, and the thermal column assembly is composed of more than three heat-resisting tubes with an upper connecting plate, a side connecting plate and a lower connecting plate. Columns 8 are press-fitted in sequence, and the heat-resisting ...

Embodiment 2

[0046] refer to Figure 1 to Figure 8 . A kind of paper mold forming equipment with self-adjustable thermal resistance, comprising an upper mold 26 and a lower mold 22, the upper mold 26 and the lower mold 22 are respectively connected with a heating plate 23, a heat conducting plate 1 and a bottom plate 5 in sequence, and the heat conducting The plate 1 and the bottom plate 5 are connected to each other through more than two heat-resistant elastic supports 4 and positioning beams. The heat-resistant elastic supports 4 include a heat-resistant column assembly, a mounting base 9 and a flange 12 in sequence from the inside to the outside. The thermal column assembly is placed in the mounting seat 9, and the mounting seat 9 is placed in the bottom plate 5. The thermal column assembly is a thermal column 8 with a lower connecting plate, and the thermal column 8 is a hollow structure. The lower mold 22 is provided with a pulp placement port, and the upper mold 26 and the lower mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com